Research Article - Der Pharma Chemica ( 2022) Volume 14, Issue 4

Thermal Behavior and Phase Transformations of Biomimetic Oxygenated Apatites

Soumia Belouafa*, Hassan Chaair and Khalid DiguaSoumia Belouafa, Laboratory of Process and Environment Engineering, Faculty of Sciences and Technologies Mohammedia. University Hassan II of Casablanca, Morocco, Email: soumia.belouafa@univh2c.ma

Received: 23-Mar-2022, Manuscript No. dpc-22-58142; Editor assigned: 25-Mar-2022, Pre QC No. dpc-22-58142 (PQ); Reviewed: 11-Apr-2022, QC No. dpc-22-58142; Revised: 14-Apr-2022, Manuscript No. dpc-22-58142 (R); Published: 22-Apr-2022, DOI: 10.4172/0975-413X.14.4.17-25

Abstract

High temperature calcination is an essential step for the production of some apatite-based biomaterials. This requires an in-depth study of thermal stability and transformations during heating.

The thermal behavior and phase transformations of biomimetic oxygenated apatites, prepared from different calcium salts (CaCO3, Ca(NO3)2, CaCl2) and orthophosphate (H3PO4), are examined, in the present work by chemical analysis, thermo-gravimetric analysis (TGA), Fourier-transform infrared spectroscopy (FTIR) and by X-ray diffraction (XRD). The thermal analysis gives evidence for the dismutation of oxygenated species (O22-, O2) at 400°C and the decomposition of the non-stoichiometric apatitic structure to a biphasic mixture (hydroxyapatite (HAP) and beta-tricalcium phosphate (β-TCP) (HAP/β-TCP)) at 900ºC.

Keywords

Apatite; Oxygenated Species; TGA; Calcination; FTIR; XRD

Introduction

Oxygenated apatites are among the most encouraging apatites by dint of their active properties which make them capable of restricting the multiplication of micro-organisms at the site of implantation. These properties result from the presence of the oxygenated species (peroxide ions: O22– and/or oxygen particles: O2) in the channels of the apatitic structure [1]. These species were released into the living environment by gradual dissolution of the material, or by exchange with the living environment. The peroxide ions so released act in situ to destroy the micro-organisms with a notable effectiveness for these species. The oxygen particles act in a particular way on anaerobic micro-organisms while locally increasing the partial pressure of oxygen.

Research on the synthesis of oxygenated apatites is exceptionally limited.

Oxygenated apatites were first prepared, in 1968, by Simpson [1]. Its method consists of a treatment with boiling, for a dozen hours, of a suspension of β-tricalcium phosphate (β-TCP) in an aqueous solution of hydrogen peroxide (H2O2).

Rey also prepared this type of apatite, in 1984, by double decomposition, in the presence of hydrogen peroxide, from calcium nitrate (Ca(NO3)2) and diammonium phosphate ((NH4)2HPO4) [2]. In the strategy of valuing Moroccan wealth, we have developed a new synthesis of oxygenated apatites by using as phosphorus precursor, orthophosphoric acid (H3PO4) derived from the first national wealth (natural phosphate) [3]. Three calcium salts have been used as calcium precursors, namely: calcium carbonate (CaCO3), calcium nitrate (Ca(NO3)2) and calcium chloride (CaCl2).

Taking into account the importance of amorphous calcium phosphates [4, 5], it seemed interesting to us to prepare poorly crystallized oxygenated apatites. We, therefore, chose to work under biomimetic conditions of pH and temperature which make it possible to obtain apatites of crystallinity similar to that biological apatites [6, 7].

These apatites can be used, without preliminary heat treatment, in several clinical filling cases: Filling after extraction, filling of peri-implant defects, filling of cavities after apical surgery and filling of periodontal pockets. In order to broaden the medical applications of these biomaterials, a consolidation of these materials by sintering is necessary. For that, we are interested, in this work, to study the thermal stability of these apatites by controlling their physicochemical characteristics according to the temperature of the thermal treatment.

Experimental

Materials and Methods

Oxygenated apatite powders are prepared by precipitation from a solution (or suspension) of calcium ions (1 M) and a solution of phosphate ions (0.6 M), according to the experimental protocol described in reference [3]:

The calcium solution (1 M) was prepared by dissolution of calcium salt (CaCO3, purity: 95%, Ca(NO3)2, purity: 99% or CaCl2, purity: 99.9%) in oxygenated water (H2O2, purity: 30%). The phosphate solution (0.6 M) was prepared by adding phosphoric acid (H3PO4, purity: 84%) in oxygenated water (30%). The synthesis method consists in putting the calcium solution into 1 L capacity reactor maintained at 37 °C. The pH was adjusted to 7.4 by addition of NH4OH solution (purity: 25%, d = 0.92). Then the phosphoric acid solution was poured into the reactor. The reacting medium was kept under agitation for 4 hours at the pH value of 7.4.

All reagents used in this study were analytical grade and were supplied by Prolabo or Merck.

After drying, the powders are ground and then characterized by different analysis techniques: chemical analysis, thermo-gravimetric analysis, Fourier-transform infrared spectroscopy and X-ray diffraction.

Five parts of each dried powder were calcined at 200, 400, 600, 750 and 900°C, respectively, for 2 hours in air. The calcined powders are characterized by chemical analysis, Fourier-transform infrared spectroscopy and by X-ray diffraction.

Calcium, phosphorus and carbonate ions and oxygenated species contents were determined by wet chemical methods:

Calcium was titrated by complexometry [8] with ethylenediaminetetraacetic acid (EDTA, purity: 99%) in the presence of ammonia. The excess EDTA is then determined with a standard solution of zinc chloride (ZnCl2, purity: 99.9%). The complexometric indicator is eriochrome black (pure). The error on the calcium content is around 0.5%.

Phosphorus contents were analyzed by colorimetry; the PO43– content is determined before calcination and that of HPO42– is obtained by the difference between the numbers of phosphorus atoms determined before (P of PO43–) and after calcination followed by hydrolysis (P of PO43– and HPO42–) [9]. The principle of this method consists in measuring, in an acidic medium, the optical density (absorbance) of the yellowish coloration of the prepared phosphovanadomolybdic complex (VO3 [P (Mo3O10)4]) at = 460 nm. The accuracy of this dosage was determined with a relative error of 0.5%.

Molecular oxygen was determined by measuring the volume displaced during the acid dissolution of powder using asbestos sodé to adsorb the CO2 released [3]. The same dosage was achieved without using asbestos sodé; the quantity in carbonate ions is determined by the difference between the two volumes [3]. Uncertainty in these dosages is about 2%.

Peroxide ions were titrated by manganimetry [10] on the acid solution resulting from the dissolution of the oxygenated apatites. The relative error on this dosage is approximately 1%.

We used a TGA TA-2950 Hi-Res with a resolution of 0.1 μg and a precision of ± 0.1%, the temperature range of this device is 25 ºC up to 1000 ºC, the sample holder boats used are made of aluminum.

For infrared absorption analysis, 1 mg of the powered samples was carefully mixed with 300 mg of KBr and palletized under vacuum. The pallets were analyzed using a Perkin Elmer 1600 FTIR spectrophotometer. X-ray diffraction analysis was carried out by means of a SEIFERT XRD 3000 P using CuK radiation. In what follows, the products obtained from the three calcium salts; CaCO3, Ca(NO3)2 and CaCl2, will be noted successively: Ap.OxCaCO3, Ap.OxCa(NO3)2 and Ap.OxCaCl2

Results and Discussion

Chemical analysis

(Table 1) shows the percentage by weight of constituent ions of the synthesized powders leading to their chemical formulas [3]:

%: percent by weight; Δ(Ca/P) = ±0.01; Δ(Ca) = ±0.005; Δ(PO4) = ±0.005; Δ(HPO4) = ±0.01; Δ(CO3) = ±0.02; Δ(O22-) = ±0.01; Δ(O2) = ±0.02.

Thermo-gravimetric analysis

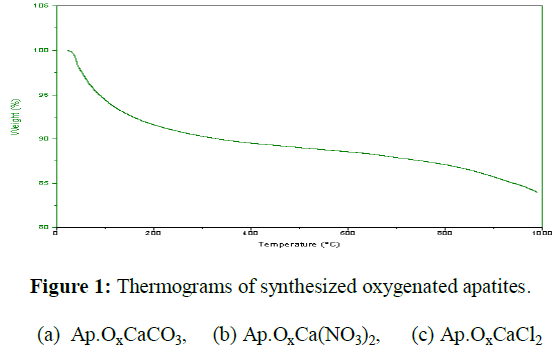

The thermograms recorded up to 1000ºC, at the heating rate 300ºC/h under nitrogen, of the washed and dried oxygenated apatites Ap.OxCaCO3, Ap.OxCa(NO3)2 and Ap.OxCaCl2) are represented in (Figure 1). These thermograms show at least three weight losses of varying amplitudes depending on the samples:

• The first weight loss takes place in a temperature range from room temperature to about 200°C. It corresponds to the departure of water molecules and adsorbed oxygen species.

• The second weight loss is approximately between 200 and 600ºC, it is attributable to the departure of oxygen and water due to the condensation of the hydrogen phosphate ions (HPO42-) depending on the reaction [11,12]:

2 HPO4 2- ⟶ P2O74- + H2O

• It is noted that it is difficult to separate the departure of water and the departure of oxygen. • The third loss, very low, occurs approximately from 600 to 800 °C. It corresponds to the release of water resulting from the reaction of the Pyrophosphate ions (P2O74-) with the hydroxide ions (OH-) of the lattice [11]:

P2O74- + 2 ⟶2 PO43- + H2O

• Finally, the Ap.OxCaCO3 exhibits additional weight loss between 800 and 1000°C. This loss can be attributed to a departure of carbon dioxide from the decomposition of the carbonate ions contained in this apatite: we have indeed seen than the Ap.OxCaCO3 contains a quantity of carbonate ions localized in the B sites [13]. These particles can be to come uniquely from calcium carbonate utilized like calcium reagent.

Isothermal calcination study

The obtained apatites were calcined in air for 2 hours at 200, 400, 600, 750 and 900 ºC, then analyzed by chemical analysis, infrared spectroscopy and X-ray diffraction.

Chemical analysis

Isothermal calcination of the obtained oxygenated apatites, washed and dried leads to significant variations in their oxygen species content (Table 2). Indeed, the calcination of the products at 200 ºC causes a significant decrease in the amount of peroxide ions (O22-) associated with a slight increase in the molecular oxygen content (O2). Beyond this temperature, there is a decrease in the content of oxygen species (O22-, O2) which disappear at 600 ºC.

| Calcination temperature (°C) | % O22- | % O2 |

|---|---|---|

| Ap.OxCaCO3 Ap.OxCa(NO3)2 Ap.OxCaCl2 | Ap.OxCaCO3 Ap.OxCa(NO3)2 Ap.OxCaCl2 | |

| Ambient | 0.69 1.27 1.49 | 0.70 1.28 1.29 |

| 200 | 0.36 1.17 1.18 | 0.75 1.32 1.34 |

| 400 | 0.04 0.06 0.08 | 0.05 0.10 0.11 |

| 600 | 0 0 0 | 0 0 0 |

| 750 | - | - |

| 900 | - | - |

Infrared spectroscopy

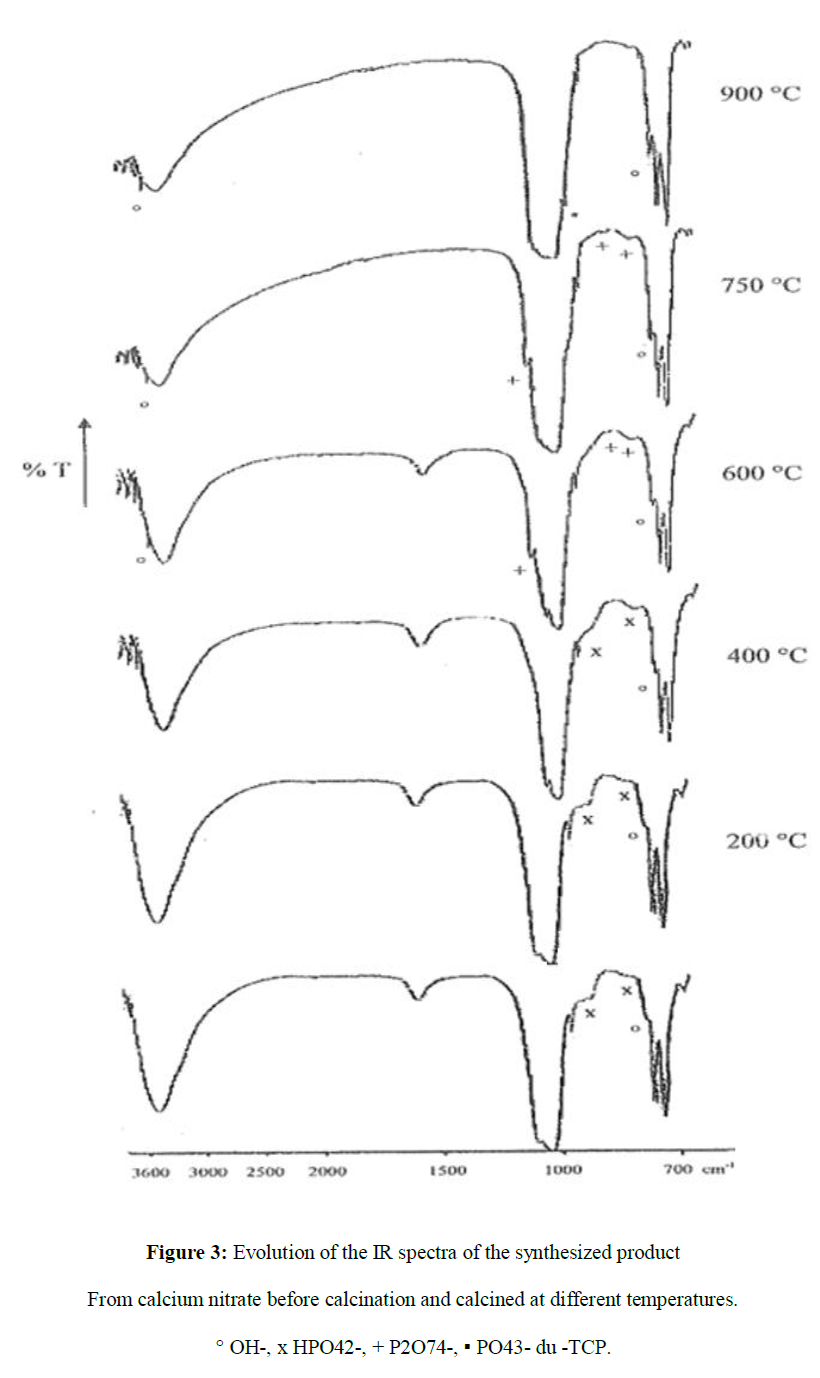

The infrared spectra of synthetized and dried powders [3] (Figure 2) (Figure 3) shows the presence of PO43– (1096-1036 cm–1 and 606-562 cm–1), HPO42– (874 cm–1), OH– (3566 cm–1) and H2O (1640 cm–1 and 3430 cm–1); characteristic bands of non-stiochiometric hydroxyapatites [14]. Furthermore, the spectrum of oxygenated apatite prepared from CaCO3 (Figure 2) shows the presence of bands attributable to the carbonate ions CO32– (1412 and 1465 cm–1); characteristic bands of type B carbonated apatites [13]. These ions can be to come uniquely from calcium carbonate utilized like calcium reagent.

Infrared spectroscopy of apatites calcined at different temperatures (Figure 2) (Figure 3) shows that the bands attributable to hydroxide ions (OH-) and hydrogenophosphate ions (HPO42-) change with increasing calcination temperature. Indeed, the rise in temperature is accompanied by a significant increase in the intensity of the OH- bands. At the same time, we observe a decrease in the intensity of the bands of the HPO42- ions which continues until around 400 °C. Beyond this temperature, we observe the appearance of the characteristic bands of pyrophosphate ions (P2O74-) (1215 cm-1, 720 cm-1) which become more identifiable at 750 °C. In addition, the characteristic band of the PO43- ions of β-TCP appears at 985cm-1 [4].

In addition, the bands attributable to carbonate ions CO32– (1412 and 1465 cm–1) don’t disappear after calcination of carbonated oxygenated apatite at 900ºC for 2 hours (Figure 3). This proves that these carbonate ions are of type B [13].

X-ray diffraction

X-ray diffraction diagrams of synthetized and dried powders [3] (Figure 4) show that the oxygenated apatites before calcination are poorly crystallized and resemble the crystallinity of the mineral part of the bone. Besides, calcined apatites retain a poorly crystallized state up to a temperature of 600ºC. Beyond this temperature, characteristic diffraction peaks of the apatitic phase become more refined. At 900ºC, characteristic diffraction peaks of a biphasic apatite, hydroxyapatite/-tricalcium phosphate (HAP/-TCP), appear [12].

The crystallographic parameters (a) and (c) that we have determined, from miller indexes of diffraction planes (002) and (300), for the formed products are grouped together in the (Table 3). This table shows that the crystallographic parameters of the product obtained after calcination of Ap.OxCaCO3 differ from those of hydroxyapatite which is the case with type B carbonate apatites [15].

| Products calcined at | Crystallographic parameters | References |

|---|---|---|

| 900°C | (a ± 0.003 , c ± 0.002) | (Hydroxyapatites calcined at 900 °C) |

| Ap.OxCaCO3 | a = 9.417 Å, c = 6.890 Å | a = 9.420 Å, c = 6.883 Å |

| Ap.OxCa(NO3)2 | a = 9.422 Å, c = 6.881 Å | (Trombe) [16] |

| Ap.OxCaCl2 | a = 9.421 Å, c = 6.881 Å |

Discussion

The study of the thermal stability of apatites prepared from CaCO3-H3PO4, Ca(NO3)2-H3PO4 and CaCl2-H3PO4 made it possible to highlight the transformations which take place in the powders during heating in the studied temperature range.

The apatites obtained, washed and dried, contain adsorbed water and structural water. The adsorbed water is removed to 200 °C (Figure 1). The so-called structural water is eliminated between 200 °C and 800 °C by progressive dehydration of the apatitic phase (Figure 1). In fact, infrared spectroscopy (Figure 2) (Figure 3) of the oxygenated apatites calcined at different temperatures, for 2 h, demonstrated the decrease in the intensity of the absorption bands of the hydrogenophosphate ions (HPO42−) between 200 and 600 °C. At 750 °C, we note the appearance of characteristic bands of pyrophosphate ions (P2O74-) which disappear at 900 °C, while the characteristic band of PO43− groups of β-TCP appears at this temperature. These observations suggest that during the heating of these apatites, reactions similar to those which have been observed by various authors in the case of calcium deficient apatites occur [17, 18]:

Studies have shown that the dehydration of hydrogenophosphate groups is in fact very complex and is accompanied by the formation of numerous intermediates (meta-phosphate ions, poly-phosphates, etc.). This process explains the temperature shift that exists between the decomposition of the HPO42− ions and the appearance of the P2O74- ions (Figure 4) [2].

The decomposition, at 900 ºC, of oxygenated apatites prepared as a two-phase mixture (HAP /β-TCP) was confirmed by X-ray diffraction (Figure 4). This decomposition can be interpreted if we consider that the obtained apatites are non-stoichiometric and that, in particular, their Ca/P ratios (Table 1) are between 1.5 and 1.667 [4].

| Products | Ca/P | % Ca2+ | % P of PO43 | % P of HPO42- | % CO32- | % O22- | % O2 |

|---|---|---|---|---|---|---|---|

| Ap.OxCaCO3 | 1.585 | 38.03 | 17.64 | 0.93 | 0.32 | 0.23 | 0.69 |

| Ap.OxCa(NO3)2 | 1.595 | 39.26 | 18.66 | 0.39 | - | 0.36 | 1.44 |

| Ap.OxCaCl2 | 1.598 | 39.34 | 18.47 | 0.58 | - | 0.35 | 1.47 |

Likewise, the X-ray diffraction diagrams reveal that the oxygenated apatites prior and after calcination at 200, 400 and 600ºC are poorly crystallized and similar to crystalline bone apatite. After 600ºC, the broad X-ray diffraction peaks characteristic of the apatitic phase becomes narrower and more defined. In fact, the sintering mechanism, called "crystal fusion", is based on the solid state diffusion of chemical species at the grain boundary and crystal growth within amorphous particles [19].

The thermal study also highlighted the evolution of oxygenated species during heating, we noticed a significant decrease in the peroxide ion content of oxygenated apatites during heating (Table 2), but we have simultaneously observed a slight increase in molecular oxygen content up to 200 °C (Table 2).

These variations correspond satisfactorily to the dismutation reaction of the peroxide ions represented by the equation [2]:

2 O22− 2 ⟶ O2− + O2

This means that a part of molecular oxygen resulting from the dismutation of peroxide ions is retained in the lattice of oxygenated apatite up to 200 °C. By heating at a higher temperature, molecular oxygen is released from the apatitic lattice until it disappears at 600 °C (Table 2).

Conclusions

The study of the thermal behavior of oxygenated apatites powders prepared, from orthophosphoric acid and calcium carbonate, calcium nitrate or calcium chloride, under biomimetic conditions of pH and T reveals that the oxygenated species responsible for the antiseptic properties of the studied apatites diffuse from the apatitic structure by heating (T > 200 °C). In effect, a part of molecular oxygen resulting from the dismutation of peroxide ions is retained in the lattice of oxygenated apatite up to 200 °C. Past this temperature, there is a lessening in the substance of oxygen species (O22-, O2) which disappear, at 600 °C. Thus, these apatites cannot be sintered without losing their oxygen species. Hence the need for consolidation of these biomaterials by very low temperature sintering such as spark plasma sintering (SPS). The objective is to keep a low crystallinity and to avoid the diffusion of oxygenated species.

REFERENCES

- Simpson DR. Am Min. 1969, 54(3-4): p.560-562.

- Rey C. National Polytechnic Institute, Toulouse, France. 1984.

- Belouafa S, Chaair H, Loukili H et al., Mater Res. 2008, 11: p.93-96.

- Heughebaert JC. National Polytechnic Institute, Toulouse, France. 1977.

- Assis CMD, Vercik LCDO, Santos MLD et al., Mater Res. 2005, 8: p.207-211.

- LeGeros RZ. Hydroxyapatite and related materials. 1994, 3: p.3-28.

- Peters F, Schwarz K and Epple M. Thermochim Acta. 2000, 361(1-2): p.131-138.

- Eanes ED and Meyer JL. Calcif Tissue Res. 1977, 23(1): p.259-269.

- Gee A and Deitz VR. Anal Chem. 1953, 25(9): p.1320-1324.

- Charlot G. Analytical chemistry methods: Qualitative and mineral analysis, Masson, Paris. 1966.

- Yubao L., Klein CPAT, Xingdong Z et al., Biomaterials. 1994, 15(10): p.835-841.

- Elfeki H, Khattech I, Jemal et al., Thermochim Acta. 1994, 237(1): p.99-110.

- Stutman JM, Posner AS and Lippincott ER. Nature. 1962, 193(4813): p.368-369.

- ASTM (American Society for Testing Materials) issues emergency standard test methods for protective-clothing. Healthc Hazard Mater Manage. 1993, 6(10):9-10.

- Trombe JC. National Polytechnic Institute, Toulouse, France. 1972.

- Vignoles M. National Polytechnic Institute, Toulouse, France. 1984.

- Bett JA, Christner LG and Hall WK. J Am Chem Soc. 1967, 89(22): p.5535-5541.

- Monma H, Ueno S and Kanazawa T. J Chem Technol Biotechnol. 1981, 31(1): p.15-24.

- Uskoković V, Marković S, Veselinović L et al., Phys Chem Chem Phys. 2018, 20(46): p.29221-29235.

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref