Research Article - Der Pharma Chemica ( 2018) Volume 10, Issue 7

The Influence of Fatty Acid Composition and Functional Groups on Fuel Related Properties of Sweet Almond (Prunus Amygdalus Dulcis) Seed Oil Methyl Esters

Esonye Chizoo1*, Onukwuli Okechukwu Dominic2 and Ofoefule Akuzuo Uwaoma3

1Department of Chemical and Petroleum Engineering, Federal university, Ndufu Alike Ikwo, P.M.B 1010 Abakaliki, Ebonyi State Nigeria

2Department of Chemical Engineering, Nnamdi Azikiwe University, P.M.B 5025 Awka, Anambra state, Nigeria

3Department of Pure and Industrial Chemistry, University of Nigeria, P.M.B 410001 Nsukka, Enugu State, Nigeria

- *Corresponding Author:

- Esonye Chizoo

Department of Chemical and Petroleum Engineering

Federal university

Ndufu Alike Ikwo

P.M.B 1010 Abakaliki, Ebonyi State Nigeria

Abstract

The physico-chemical properties of the biodiesel prepared from Sweet almond seed oil was determined and discussed in accordance with ASTM D6751 and DIN 14214 standards for biodiesel. The influence of the fatty acid composition and functional groups on the fuel related properties was carried out using Gas Chromatography-Mass Spectrometry (GC-MS) technique and Fourier Transform Infrared Radiation (FTIR) spectroscopy analyses respectively. The presence of C-H indicates the presence of properties as pour and cloud point that affect the performance of biodiesel during cold weather engine operations but the biodiesel sample was found to contain more C=C that can cause it to remain in liquid state with tendency of poor storage stability. It was equally observed that the Sweet Almond Seed Oil Methyl Ester (SASOME) is mainly composed of monounsaturated fatty acid and expected to possess low values for density, viscosity, heating value and thermal efficiency with average cetane number. This would subsequently be translated into low HC, CO and smoke emissions.

Keywords

Fatty acid composition, Functional groups, Sweet almond, Fuel properties, Methyl ester.

Introduction

The awareness of energy issues and environmental challenges associated with fossil fuel combustion has encouraged investigation on the possibility of using alternative sources of energy. Therefore, replacing petroleum with an inexpensive and renewable resource that can be produced globally has been proposed to be leading efforts towards a second green revolution for human needs going beyond food [1]. Biofuels research has taken aim at augmenting petroleum liquid fuels with chemicals derived from crop and forest residues, algae and birdlimed waste materials with the aim of eventually replacing them. Convinced with scores of reasons, industries and researchers have turned to available technologies in an attempt to begin to displace petroleum fuels immediately. But these technologies were found to have adversely resulted in increase of food prices that rose up to 4.0% in 2007 and 5.5% in 2008 [2]. Consequently, biofuels research drifted more to non-food sources resulting in the existence of first and second generations of biofuel sources. Among them biodiesel attracted more interest for many obvious reasons: it is highly biodegradable, has minimal toxicity and can replace diesel fuel in various applications such as in boilers and internal combustion engines with little modifications. Little decrease in performances has been reported with almost zero emissions of chemical compounds and other substances that degrade the environment. The whole life cycle analysis shows that it has small net contribution to CO2 which results in significant improvement of rural economic potentials [3]. Biodiesel is produced through a chemical process known as transesterifiction. Transesterifiction of vegetable oils with low molecular weight simple alcohols has been discovered as the best approach to reduce the high viscosity, low volatility, heavy engine deposits and toxic substance formation related to the direct application of vegetable oils in combustion engines [4]. A considerable amount of research has been conducted on feedstocks for biodiesel production mainly using non-edible oil seeds such as Jatropha curcas, Mahua, Pongamia, Cotton seed, Karanja, Neem, Jojoba, Moringa, Rubber seed, Passion seed, Tobacco seed, Salmon Oil, Tall, Coffee ground, etc. [5], but little has been reported on Sweet Almond seed.

Almond plants are included in the family Rosaceae in addition to promoideae (apples, pears), prunoideae (apricot, cherry, peach and plum) and rosoideae (blackberry, strawberry) fruits [6]. The almond is native to the Mediterranean climate region of the Middle East. It was spread by humans in ancient times along the shores of Mediterranean into Northern Africa and Southern Europe and recently transported to other parts of the world notably California, United States [7]. World production of almond was 2.9 million tonnes in 2013 with United States as the largest producer of 1.8 million tonnes (FAOSTAT, 2014). The two major varieties of almonds are the bitter almond (Prunus amygdalus “amara”) and the sweet almond (Prunus amygdalus “dulcis”) which found useful application in culinary purposes and making of oils and flavourings respectively [8]. Almond fruit consists of four portions: comprising the kernel or meat, middle shell, outer green shell cover or almond hull with a thin leathery layer referred as brown meat or seed coat [9]. Sweet almond tree is found in the south eastern and south southern part of Nigeria.

They provide shades to homes, offices and the environment [10]. Their fruits litter the environment and are picked either by children or disposed off as wastes and as such their use as feedstock for biodiesel production would also serve as a waste disposal option. Giwa and Ogunbona, [6] studied the extraction and characterization of the seed oil biodiesel from sweet almond obtained from Nigeria. Their study revealed that the seed oil has an oil yield of 51.45%, acid value of 1.07 mg KOH/g and fatty acid composition of oleic acid (69.7%), linoleic acid (18.2%) and palmitic acid (9.3%). Their result equally showed that the cold flow properties were -3 and -9 for the cloud point and pour point respectively with the specific fuel properties found to satisfy both EN 14214 and ASTM D6751 biodiesel standards. Mehdic and Kariminia, [11] also studied the optimization of biodiesel production from Iranian bitter almond oil using statistical approach. Their investigation revealed that at the following optimal conditions: temperature of 35ºC, catalyst concentration of 1.4 wt% and methanol to oil molar ratio of 9.7 mol/mol, the actual values of the product yield, biodiesel yield and biodiesel purity were 96.7, 94.7 and 97.9 wt% respectively while the predicted values were 98.1, 96.3 and 98.2 wt% respectively. Amongst the reported works on biodiesel production studies from sweet almond oil so far none has focused on detailed spectroscopic studies on the feedstock.

The Fourier Transform Infra-Red (FT-IR) spectroscopy has an excellent potential in providing qualitative and quantitative data for fuels including biodiesel with little or no vigor during the sample preparation. It has been reported to have been applied extensively as a quantitative analytical method for investigating edible oil quality parameters [12]. Similarly, it was developed for determining the acidity and moisture content in lubricants [13], as well as providing information about the functional groups in molecules and the structure of molecular vibration [14]. Gas Chromatography-Mass Spectroscopy (GC-MS) analysis mainly identifies the quality and quantity of the produced biodiesel in the methyl esters present in the product sample and applied to ascertain specific methyl esters predominant in the produced FAME [15]. Many works have been done on the application of FT-IR and GC-MS to characterize biodiesel samples [16,17] but none has been carried out to determine the effect of fatty acid compositions and functional groups on the fuel related properties of Sweet Almond Seed Oil Methyl Esters (SASOME).

This work therefore seeks to ascertain the prevalent functional groups and fatty acids in biodiesel produced from sweet almond seed oil and their effect on fuel related properties using FT-IR and GC-MS techniques.

Materials and Methods

Materials

Sodium hydroxide (99% Sigma-aldrich), potassium hydroxide (loba chemie, gmbH 85%), methanol (Merck, Germany 99.5% purity), carbon tetrachloride (chloroform), Wij’s solution (iodine monochloride), potassium iodide solution and phenolphthalein (Merck Germany) were all of analytical grade.

The Fresh fruits of the Sweet Almond were sourced locally in Nigeria. The fruits were washed properly and separated into seeds and pulp. The husks containing the seeds were sun-dried for 5 days to ensure free movement of the seed (an indication of readiness for seed separation). The seed were manually separated from hulls by cracking and the seeds collected were sun-dried in the open for 7 days. The oil was extracted using n-hexane with repeated extractions after which it was recovered from the solvent by rotary evaporator. The oil was allowed to further dry in the open air and was subsequently degummed to remove phosphatides, lysophasidic acids which are strong emulsifiers which lower the yields of neutral oils.

Analytical methods

The properties of the sweet almond seed oil were determined in accordance with Association of Official Analytical Chemists (AOAC) [17] method (the acid value by AOAC Ca5a-40, saponification value by AOAC 920:160; iodine value by AOAC 920:158 and peroxide value by AOAC 965.33) while the viscosity was determined by using Oswald viscometer apparatus, the density by using density bottle, moisture content by the Rotary Evaporator Oven (BTOV 1423), the ash content by heating to dryness in Veisfar Muffle furnance and the refractive index by using Abbe Refractometer (Model: WAY-25, Search tech. Instruments). The fuel properties of the synthesized biodiesel were determined by ASTM standards: the kinematic viscosity was determined by ASTM D-445 method, the density was determined by ASTM D-1298 method, and the pour point determination was made using ASTM D-97 methods. The flash point of the fuel was determined as ASTM D-93, the value of cloud point was estimated according to ASTMD-2500, and Acid value was measured following the ASTM D-664 method. Cetane Number (CN) was calculated by the equation developed by Patel [18] (Equation 3), the FAME content in percentage was obtained by using correlation developed by Felizardo et al. [19] (Equation 4), while the Higher Heating values were determined by using correlation applied by Sivaramakrishnan and Ravikumar, [20] (Equations 5 to 8).

The Oil and Biodiesel yield were calculated using the following expressions (Equations 1 and 2)

% Oil Yield=((Grams of Oil Extracted)/(Grams of Seed Meal used))×100 (1)

% Biodiesel Yield=((Grams of methyl ester produced)/(Grams of Oil taken))×100 (2)

Cetane Number (CN) = CI-2.6 (3)

Where CI-Cetane Index

FAME%=-45.055 lnμ+162.85 (4)

Where μ-kinematic viscosity

HHV=0.0317V+38.053 for vegetable oil (5)

=0.4625V+39.450 for biodiesel based on Viscosity (6)

=- 0.0259ρ+63.776 for biodiesel; based on density (7)

=0.021FP+32.12 for biodiesel based on flash point (8)

Where V-viscosity (cP), ρ-density(g/ml) and FP-Flash point(˚C)

The mid Infrared spectra of oil and biodiesel samples were obtained in Fourier Transform Spectrometer by IR Affinity-1 Shimadzu, Japan FJS: JPN patent No: 2115670, No 3613171 and JPN reg. of utility model No: 3116465. The FT-IR has SN ratio of its class of 30000: 1, 1 minute accumulator in the neighborhood of 2100 cm-1 peak to peak with a maximum resolution of 0.5 cm-1 in the region of 400 cm-1-4000 cm-1. The gas chromatographic analysis was carried out using GCMS-QP2010 plus, Shimadzu, Japan instrument. The GC column used was calibrated by inject ting methyl ester standards. Good separations were achieved by diluting the sample in a small amount of ethyl acetate. The carrier gas used was hydrogen and its flow rate was regulated at 41.27 ml/mins while the column flow was at 1.82 ml/min. The oven temperature was set at 80ºC before ramping up at 6ºC /min until 340ºC. The identification of peaks was done by comparison of their retention time and mass spectra with mass Spectra Library (NIST05s LIB).

Experimental procedures

The oil was heated fairly at 8ºC for 30 min using Gallenkamp Magnetic Stirrer thermostat hot plate (Weiss Technik England) to reduce the viscosity of the oil.

Sodium methoxide was prepared by adding 2% weight of oil of NaOH to 175 ml of methanol and stirred at 300 rpm until it dissolved completely for about two minutes in the reaction vessel. The Base transesterifiction was carried out at catalyst concentration of 1.5%, reaction time of 65 min, methanol to oil molar ratio of 5: 1 and temperature of 50ºC in a Sohxlet extractor fitted with thermo-regulator heater and stirrer. 200 ml of the oil was measured into the flask and was heated to the specified temperature. The Sodium methoxide was then poured into the flask containing oil and was immediately covered. The temperature was maintained for the specified time at constant agitation. After the base transesterification process, the biodiesel was allowed to settle for 24 h inside a separatory flask to allow clear separation of biodiesel from glycerol by gravity. This was subsequently separated by removing the glycerol from the bottom of the flask. Purification of the biodiesel was carried out by washing with distilled water (20% of biodiesel volume at 50ºC). This was carried out five times until a clear biodiesel was obtained. Drying of the biodiesel was carried out by adding anhydrous CaCl2 and heating gently to 50ºC till the CaCl2 had adsorbed the moisture. This was also separated from the biodiesel to obtain a clean, dry methyl ester. The volumetric yield of the biodiesel was noted.

Results and Discussion

Tables 1 and 2 show the physico-chemical properties of the Sweet Almond Seed Oil (SASO) and the Sweet Almond Seed Oil methyl ester (SASOME) respectively.

| S. No. | Parameters | Results |

|---|---|---|

| 1 | Yield (%) | 60.15 |

| 2 | Colour | Golden |

| 3 | Density (g/m3) | 855.2 |

| 4 | Moisture content (%) | 0.57 |

| 5 | Refractive Index | 1.4472 |

| 6 | Saponification Value (mg KOH/g ) | 165.5 |

| 7 | Iodine Value (g/100 g) | 35.77 |

| 8 | Peroxide Value (milli eq. oxy/kg) | 1.48 |

| 9 | Acid value (mg KOH/g) | 2.805 |

| 10 | Free Fatty Acid as oleic (%) | 1.402 |

| 11 | Ash Content (%) | 1.02 |

| 12 | Viscosity (cP) | 8.05 |

| 13 | Smoke point (˚C) | 40 |

| 14 | Titre point (˚C) | 52 |

| 15 | Flash point (˚C) | 157 |

| 16 | Cloud point (˚C) | -2 |

| 17 | Higher Heating Value(HHV) (MJ/kg) | 38.31 |

Table 1: Physico-chemical properties of SASO

| S. No. | Parameter | SASO FAME | ASTM D 9751 | ASTMD 6751 | DIN 14214 |

|---|---|---|---|---|---|

| 1 | Biodiesel Yield (%) | 94.36 | - | - | - |

| 2 | Seed Oil Yield (%) | 60.15 | - | - | - |

| 3 | Density (g/m3) | 849.1 | 850 | 880 | 860-900 |

| 4 | Moisture content (%) | 0.02 | - | - | - |

| 5 | Refractive Index | 1.4402 | - | - | - |

| 6 | Acid value (mgKOH/g) | 0.46 | 0.062 | 0.5 | 0.5 |

| 7 | Free fatty acid (%) | 0.23 | 0.31 | 0.25 | 0.25 |

| 8 | Iodine value (mgKOH/g) | 28.02 | 42-46 | - | 120 max |

| 9 | Saponification value (mgKOH/g ) | 161.05 | - | - | - |

| 10 | Ash Content (%) | 0.01 | 0.01 | 0.02 | 0.02 |

| 11 | Kinematic viscosity (mm2/s) | 4.75 | 2.6 | 1.9-6.0 | 3.5-5.0 |

| 12 | Smoke point ( ºC ) | 34 | - | - | - |

| 13 | Fire point ( ºC ) | 40 | - | - | - |

| 14 | Flash point ( ºC ) | 136 | 60-80 | 100-170 | 120 |

| 15 | Cloud point ( ºC ) | -2 | -20 | 3 to 12 | - |

| 16 | Pour point ( ºC ) | -6 | 35 | 15 to 16 | - |

| 17 | Calorific Value (KJ/Kg) | 31178.39 | 42-46 | - | 35 |

| 18 | Conductivity (Us/CM) | 0.4 | - | - | - |

| 19 | Cetane Index | 73 | - | - | - |

| 20 | Cetane Number | 70.4 | 40-55 | 47 min | 51 min |

| 21 | Higher Heating Value(HHV)a (MJ/kg) | 34.72 | - | - | - |

| 22 | Higher Heating Value(HHV)b (MJ/kg) | 40.76 | - | - | - |

| 23 | Higher Heating Value(HHV)c (MJ/kg) | 63.75 | - | - | - |

| 24 | % FAME | 92.27 |

min-minimum, max- maximum

Table 2: Physico-chemical properties of the SASOME

The physico-chemical properties of the biodiesel (Table 2) showed that the ash content, specific gravity, saponification value, viscosity, acid value and iodine value decreased when compared with the values obtained from the seed oil. This indicates improved fuel quality after the transesterification process. Densities and other gravities are important parameters for diesel fuel injection systems. The value obtained was within the standard limit of ASTM D6751 and DIN14214. The Ash content of the biodiesel sample was below the maximum limit of ASTM and EN standards. This indicates that it may not likely have high mineral contents that would lead to presence of high level of air pollutants like SOX and NOX [21]. Viscosity is important in determining optimum handling, storage and operational conditions since liquid fuels need to have suitable flow characteristics to ensure that adequate supply reaches injectors at different operating temperatures The value was lower than 5.5 mm2/s obtained from Neem seed oil reported by Awolu and Layokun, [22], 3.01 mm2/s obtained from corn oil reported by De Lima et al. [23], 8.08 mm2/s obtained from tigernut oil reported by Ofoefule et al. [21] and 4.23 mm2/s obtained from sweet almond oil reported by Giwa and Ogunbona, [6] but compared well with 2. 56 mm2/s obtained from waste cooking oil (WCO) reported by Adepoju and Olawale, [24]. Oil with high viscosity can form droplets on injection which result in poor atomization. The Acid value obtained after transesterification was within the limit of ASTM D6751 and EN14214 which is an indication of good biodiesel quality. These values compare well with the results from other researchers [6,23], but lower than 1.122 obtained from tigernut oil biodiesel by Ofoefule et al. [21] and 3.86 obtained from waste cooking Oil (WCO) biodiesel by Adepoju and Olawale, [24]. The iodine value is an index of the number of double bonds within a mixture of fatty acids contained in biodiesel. Therefore, it is a measure of the total unsaturation of a fatty material. The iodine value of the methyl ester satisfied the specification recommended by EN 14214 standards. The value was lower than 70.5 from Neem oil biodiesel [22], 116 for WCO biodiesel [24], 98.38 for tigernut biodiesel [21]. The Calorific value fell below ASTM standards but within EN standards. These values support the values obtained on higher heating values based on flash point (34 MJ/kg). The values obtained compared with 39.89 MJ/kg obtained from Neem oil biodiesel [22]. These are important low temperature fuel parameters. SASOME had satisfactory Cloud point (CP) and Pour point (PP) values of -2, and -6 respectively, which are quite within the -3 to 12 and -15 to 16 ASTM D6757 standards for CP and PP respectively. The result is as a result of the higher percentage of long-chain unsaturated fatty acids in SASOME [6]. Moreover, since the pour point is the lowest temperature at which frozen oil can flow and is used to specify the cold temperature stability of fuel oil, this shows that the produced biodiesel would perform well in very cold and temperate regions. The Cetane number (CN) of the sweet almond biodiesel was within the minimum standard limits of ASTM and EN (47 and 57 respectively) and compares well with the results of Sivaramakrishnan and Ravikumar, [20] who obtained CN values of 63, 54, 45, 49, 54 and 62 for Babassu, Rapeseed, Soyabean, Sunflower, Peanut and Palm respectively It implies that SASOME would give low delay period and smooth engine operation.

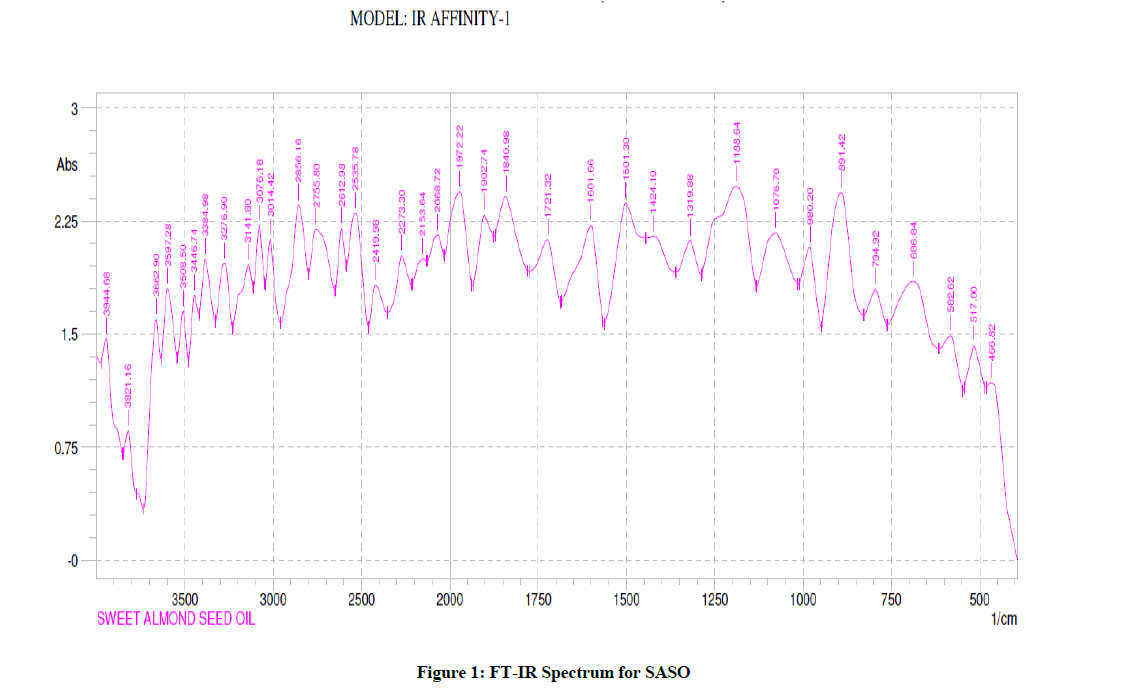

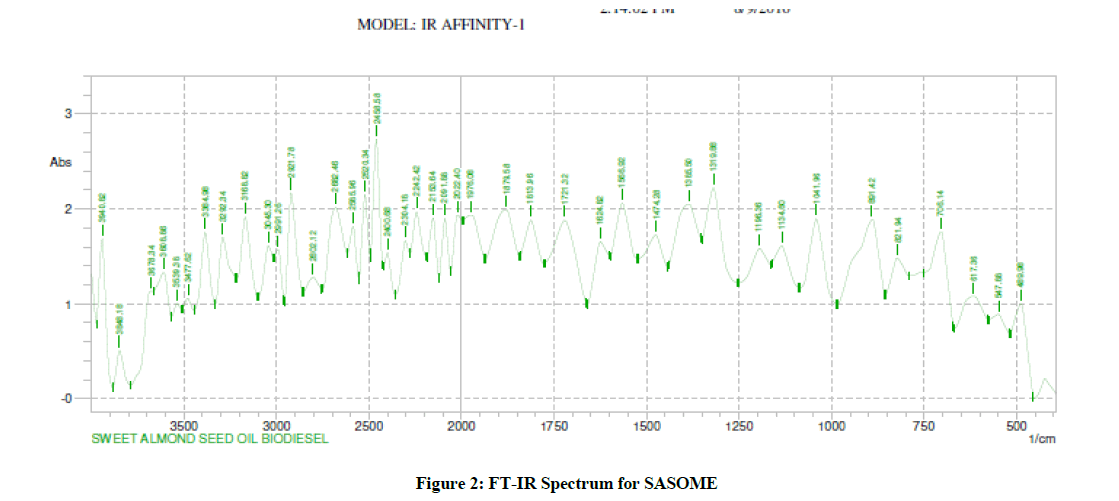

From the spectrum of SASO and SASOME (Figures 1 and 2), the specific peak 891.42 cm-1 indicate the presence of =C–H functional group and possesses bending type of vibrations which appeared at low energy and frequency region in the spectra. They are doubly bonded and attributed to as unsaturated. They are part of fatty acid methyl ester with unsaturated bond in the triglyceride and ester [25]. The following bonds are typical of an ester C=O, C–O, C–C, C–H and O-H. The characteristic peaks found in the region 1076.70 cm-1 and 1196.40 cm-1 show split stretching of C–O and rocking vibration of C–O as carbonyl groups for SASO and SASOME [25,26]. It was observed that 1188.64 cm-1 in the oil sample got split into two definite signals at 1134.60 and 1196.36 cm-1. The band region between 1319.88-1501.30 cm-1 and 1319.88-1566.92 cm-1 for SASO and SASOME spectral respectively could be ascribed to the bending and rocking vibrations of methyl group in the glyceride and ester [27]. The band region between 1721.32-1840.98 cm-1 and 1721.32 -1813.96 cm-1 for SASO and SASOME spectral respectively can be ascribed to the stretching vibrations of C=O group indicating the conversion of the triglyceride, to methyl esters. The characteristic bands of 2419.98 cm-1 and 2400.68 cm-1 appear with C≡C (alkyne group) for SASO and SASOME while the band region between 3384.98- 3597.28 cm-1 and 3384.98-3608.86 cm-1 for SASO and SASOME respectively can be ascribed to O–H stretching vibrations which are single bonded and appear at high energy level.

Effect of prevalent functional groups on fuel related properties

The characteristic peaks in the biodiesel showed the range of the functional groups which indicate the presence of the following functional groups: alkyl, methyl, methylene, alcohol, ester and carbonyl. The peak analyses of both spectra show significant differences effected by the ester groups. The change from ester groups to concrete methyl ester was observed to has the strongest impact in the infrared spectrum. All aspects regarding the carbonyl groups were visible in the SASOME while additional chains representing palmitic, stearic, oleic and linoleic acid were visible in both the vegetable and biodiesel spectra with the –CH2 hydrocarbon part. The single bond functional group O-H was observed to be prevalent in the biodiesel with both stretch and hydrogen bonding. The presence of undesirable water molecule was evidenced by the hydrogen bonding [13]. The presence of C-H can be attributed to the presence of properties such as pour and cloud points that influences the performance of biodiesel during cold weather engine operation [13] but the presence of carbon to carbon (C=C, C≡C) unsaturated bonds which are the most abundant can cause the biodiesel samples to remain in liquid state but may be liable to poor storage stability due to oxidation. This implies that the biodiesel would not need cold flow improver for better performance. However, all the absorptions corresponding to C-O and C=O stretches indicate that the biodiesel product contains ester functional groups typical to any biodiesel type.

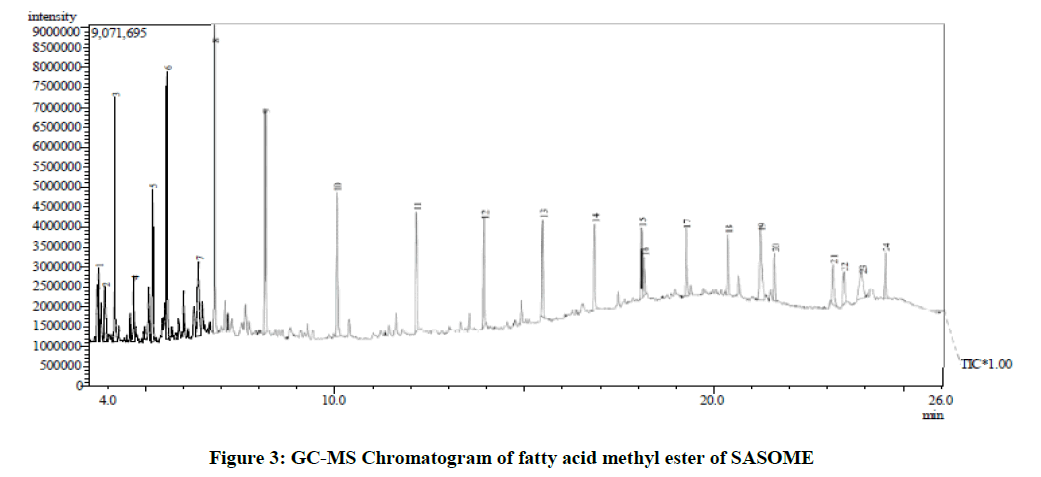

The fatty acid chromatogram showing the different components present in SASOME is shown in Figure 3. Twenty four (24) peaks were recorded which showed different fatty acid methyl esters present.

The major fatty acid component present in SASOME is oleic acid followed by α-linoleic acid and palmitic. Other organic compounds detected by the GC–MS in SASOME include hexadecane and hexanaldimethyl acid. These results are in line with the results obtained by Botinestean et al. [28], who identified decane, tetralin and hexadimethyl acetal in tomato seed oil by GC -MS and those obtained by Sharmila and Jeyanthi, [29] who identified over six non-fatty acid methyl esters through GC-MS of Cladophora vagabund.

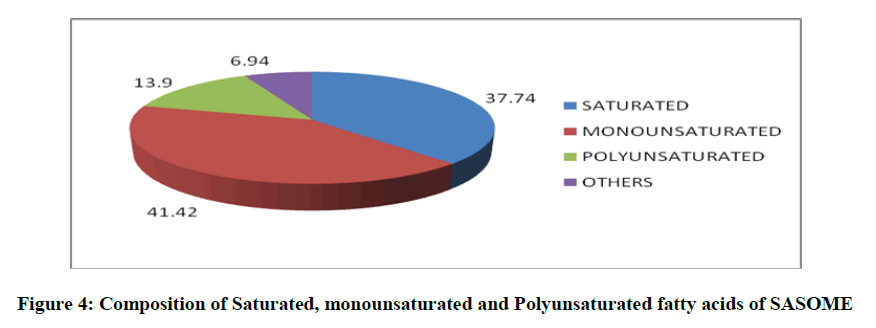

From Table 3 and Figure 4, SASOME contains total of 37.74% saturated fatty acid, 41.42% monounsaturated fatty acid and 13.90% polyunsaturated fatty acid.

| Peak | Retention Time | Fatty Acid | % |

|---|---|---|---|

| 1 | 3.766 | Capric acid methyl ester | 1.06 |

| 2 | 3.929 | Caprylic acid methyl ester | 1.36 |

| 3 | 4.201 | Stearic acid methyl ester | 1.32 |

| 4 | 4.695 | Eicosenic acid methyl ester | 7.14 |

| 5 | 5.192 | Erucic acid methyl ester | 0.73 |

| 6 | 5.572 | Palmitic acid methyl ester | 7.88 |

| 7 | 6.407 | Lignoceric acid methyl ester | 4.75 |

| 8 | 6.845 | Oleic acid methyl ester | 40.34 |

| 9 | 8.179 | α- Linoleic acid methyl ester | 8.07 |

| 10 | 10.076 | Palmtoleic acid methyl ester | 0.58 |

| 11 | 12.171 | Elaidic acid methyl ester | 1.09 |

| 12 | 13.953 | Arachnidic acid methyl ester | 4.3 |

| 13 | 15.953 | Behenic acid methyl ester | 3.71 |

| 14 | 15.868 | Myristic acid methyl ester | 3.69 |

| 15 | 18.111 | Hexadecane | 0.69 |

| 16 | 18.185 | 9-dodecanoic acid methyl ester | 0.54 |

| 17 | 19.26 | Pentadecanoic acid methyl ester | 0.56 |

| 18 | 20.347 | Hexanaldimethyl acid | 0.41 |

| 19 | 21.214 | Linolenic acid methyl ester | 0.83 |

| 20 | 21.582 | Gadolic acid methyl ester | 0.14 |

| 21 | 23.13 | 5-octadecanolenic acid methyl ester | 0.63 |

| 22 | 23.41 | γ-linoleic acid methyl ester | 3.41 |

| 23 | 23.875 | Vaccenic acid methyl ester | 1.78 |

| 24 | 24.512 | 10-undecanoic acid methyl ester | 1.97 |

Table 3: Fatty Acid Profile of SASO FAME

Influence of fatty acid composition on the fuel related characteristics

In biodiesel standards the specifications that a biodiesel must meet are related with composition and structure of fatty esters inherent in the biodiesel [30]. These qualities include cetane number, kinematic viscosity, oxidative stability and cold flow properties in the form of cloud and pour points [15]. Other essential properties influenced by fatty acid esters components of biodiesel but not contained in biodiesel standards are exhaust emission, lubricity and heat of combustion [15]. Knothe [15] has reported that methyl oleate can be the desirable fatty acid among the other common fatty acids that can enrich the fuel properties of biodiesel produced. The presence of low levels of saturated and polyunsaturated fatty acids and the prevalence of high levels of monounsaturated fatty acids in biodiesel sample equally enhance properties of high quality biodiesel [15]. In this study, the sweet almond seed oil methyl ester (SASOME) is observed to contain high levels of monounsaturated fatty acids and more of methyl oleate, it would therefore possess good fuel properties. The presence of higher composition of unsaturated fatty acids in the SASOME as shown in Table 3 and Figure 4 would equally enhance cold flow properties like cloud point and pour point but promote poor oxidative stability. This supports the result of FT-IR and physico-chemical properties analyses. The application of SASOME would not result in micro-crystal formation which has been reported to cause serious problems in fuel lines and engine filter because vegetable oils with less content of trans fatty acids and saturated fatty acids tend to possess high viscosity at lower temperatures. Again a high value of cetane number (CN) above 80 has been observed in saturated FAME, a medium range (55-58) in monounsaturated FAME and low value (20-40) in feedstock predominant in unsaturated fatty acids. In the present study, the cetane number is found to be in the medium range (Table 2), reflecting the dominance of monounsaturated fatty acids. The presence of higher concentrations of higher melting point saturated long chain fatty acids in biodiesel feedstocks tends to promote poor cold flow properties [31]. Highly saturated compounds like tallow methyl ester has cloud point of 17ºC while palm oil methyl ester possess cloud point of 13ºC. On the contrary, feedstock with relatively low concentrations of saturated long chain fatty acids such as linseed, olive, rape seed and safflower oils tend to yield biodiesel with cloud point less than 0ºC. In this study, Sweet almond seed oil biodiesel cloud point was determined as -2ºC which shows the occurrence of more unsaturated fatty acid than saturated fatty acids [32-37].

Conclusion

Methyl ester from the seed oil of Sweet almond (Prunus amygdalus dulcis) was synthesized by transesterification using optimized base-catalyzed methanolysis. The physico-chemical parameters of the biodiesel were found to meet the ASTM D 6751 and DIN 14214 standards. The formation of fatty acid methyl esters (FAMEs) was confirmed by FT-IR and GC-MS analyses. The result showed the dominance of monounsaturated fatty acids with average cetane number in the biodiesel fuel. It is expected to possess enhanced cold flow properties, low thermal efficiency and poor storage stability when compared with fuels with high levels of saturated fatty acid composition. This would subsequently be translated into lower HC and CO emissions when compared with highly saturated biodiesel.

Author’s Contribution

C. Esonye, carried out the experimental work, O.D. Onukwuli, and C. Esonye, designed the experiment and A.U. Ofoefule, supervised the experiment and proof read the manuscript. All the authors read and approved the final manuscript.

Acknowledgement

The authors are grateful to the National Centre for Energy Research and Development (NCERD), University of Nigeria Nsukka and National Research Institute for Chemical Technology (NARICT), Ahmmadu Bello University (ABU), Zaria Nigeria for the availability of the laboratory facilities, apparatus and analytical equipment.

Funding

This research did not receive any specific grant from funding agencies in public, commercial, or not-for-profit sector.

Competing Interest

The authors declare that there is no conflict of interests with any financial organization regarding the materials discussed in the paper.

References

- B.P. Mooney, The second green revolution, Production of plant biodegradable plastics, Biochem. J., 2009, 418, 219-232.

- M.A. Martin, N. Biotechnol., 2010, 27, 596-608.

- M. Ahmad, H. Sadia, M. Zafar, S. Sultana, M.A. Khan, Z. Khan, Energy Sources Part A.,2012, 34, 1480-1490.

- R.D. Tesser, M. Serio, M. Giuda, M. Nastasi, P. Santaceraria, Ind. Eng. Chem. Res., 2005, 44, 7978-7982.

- A.E. Atabani, A.S. Silitonga, A.B. Irtan, T.M.I. Mahlia, H.H. Masjuki, S. Mekhilef, Renewable and Sustainable Energy Review., 2012, 16, 2070-2093.

- S. Giwa, C. Ogunbona, Rev. Ambient Aqua., 2014, 9(1).

- R. Mark, Introduction to fruit crops” published online, retrieved from: https://en..wikipedia.org/w/index.php, 2006.

- S.O. Agunbiade, J.O. Olanlokun, Pakistan J. Nutr., 2006, 5, 316-318.

- J.E. Ali, J. Rashid, J.E. Rana, Food Chem.,2010, 120(2), 349-360.

- A. Mehdic, H. Kariminia, Applied Energy., 2011, 88(7), 2377-2381.

- F. Ma, M.A. Hanna, Bioresrouce. Technol., 1999, 70, 1-15.

- F. Van de Voort, A. Alawi, J. Sedman, Appl. Spectro., 2006, 59(10), 1295-1299.

- M. Ndana, J.J. Grace, F.H. Baba, U.M. Mohammed, Int. J. Sci. Envi. Tech., 2013, 2(6), 1116-1121.

- M.F. Elkady, Z. Ahmed, B. Ola, J. Chem., 2015, 2015, 9.

- G. Knothe, Energy and Environ. Sci.,2009,2, 759-766.

- O.D. Silverster, D. Innocent, Y. Mohammad, N. Isioma, O. Linus, European Int. J. Sci. Tech., 2013, 2(7), 1317-145.

- AOAC, Official methods of analysis, (13th Edn.), Association of Official Analytical Chemists, Washington, DC, 1990.

- V. Patel, Cetane Number of New Zealand diesel, Report, office of Chief Gas Engineer, Energy Inspection Group, Ministry of Commerce Press, Wellington, New Zealand, 1999.

- P. Felizardo, M.J. Correia, I. Raposo, J.F. Mendes, R. Berkemeier, J.M. Bordado, Waste Manage., 2006, 26(5), 487-494.

- Sivaramakrishnan, P. Ravikumar, Asian J. Appl. Sci., 2012, 7(2), 205-211.

- A.U. Ofoefule, C.N. Ibeto, U.C. Okoro, O.D. Onukwuli, Phys. Rev. Res. Int., 2013, 3(2), 145-153.

- O.O. Awolu, S.K. Layokun, Int. J Energy and Environ. Engg., 2013, 4, 39.

- A.P. De Lima, A.L. De Lima, D.Q. Santos, W.B. Neto, Rev. Virtual. Quim., 2013, 5(5), 817-827.

- T.F. Adepoju, O. Olawale, Chemical and Process Eng. Res., 2014, 21, 80-84.

- N. Saifuddin, H. Refai, Res. J. Appl. Sci. Eng. Technol., 2014, 8(9), 1149-1159.

- M.M. Conceicao, V.J. Fermardes, A.S. Araiyo, M.F. Farais, I.M. Santos, A.G. Souza, J. Energy Fuel., 2007, 21(1), 1522-1527.

- E.D. Gunstone, JAOCS.,2004, 33, 132-139.

- C. Botinestean, N.G. Hadaruga, D.J. Hadaruga, I. Jiami, J. Agroalimentary Process & Techn., 2012, 18(1), 89-94.

- S. Sharmila, L.R. Jeyanthi, J. Chem. Pharmaceut. Res., 2012, 4(11), 4883-4887.

- M. Mittlebach, C. Remschnodt, Biodiesel the comprehensive Handbook, Boersedruck Ges MBH, Vienna, 2004.

- R.O. Dunn, Cold weather properties and performance of biodiesel, In: G. Knothe, J.V. Gerpen, J. Krahl, (Edi.), the biodiesel Handbook, chapter 6.3. Champaign, IL, USA, AOCS Press, FAOSTAT, 2005, Production /Crops for almond with shell” food and agriculture Organization of United Nations, Statistics division.

- C.C. Enweremadu, O.J. Alamu, Int. Agro Physics., 2010, 24, 29-34.

- G. Knothe, J. Knahl, J. Van Gerpen, The biodiesel handbook, AOCS press Champaign, IL, 2005, 42.

- G. Knothe, Chem. Phys. lipids., 2012, 50, 14-34.

- Octave, S. and Thomas, D., Biochem., 2009, 91, 659-64.

- A.Y. Oyerinde, E.I. Bello, British J. Appl. Sci. Tech., 2016, 13(3), 1-14.

- J.A. Rodrgues, F.P. Cardoso, E.R. Lachter, L.R.M. Estevao, E. Lima, R.S.V. Nascimento, J. Am. Oil Chemists’ Society., 2006, 83, 353-357.