Research Article - Der Pharma Chemica ( 2024) Volume 16, Issue 5

Synthesis of Biodiesel from Waste Cooking Oils Using Chicken Eggshell-Derived Calcium Oxide: A Sustainable Approach

Sownthari K*, Nithila Priya B and Josephine DianaSownthari K, Department of Physics, Stella Maris College, Chennai, India, Email: sownthari@gmail.com

Received: 30-Sep-2024, Manuscript No. DPC-24-146542; Editor assigned: 03-Oct-2024, Pre QC No. DPC-24-146542 (PQ); Reviewed: 17-Oct-2024, QC No. DPC-24-146542; Revised: 18-Oct-2024, Manuscript No. DPC-24-146542 (R); Published: 29-Oct-2024, DOI: 10.4172/0975-413X.16.5.482-487

Abstract

The need for clean, renewable energy sources has led to extensive research in the field of biodiesel production. This study explores the synthesis of biodiesel from waste cooking oils, including sunflower oil, palm oil and coconut oil, using a novel catalyst derived from chicken eggshells. The catalyst, Calcium Oxide (CaO), was prepared through a simple calcination process, effectively utilizing eggshell waste. The biodiesel production process involved transesterification, wherein the waste oils were reacted with methanol in the presence of the CaO catalyst. The synthesized biodiesel was characterized using ASTM standards for viscosity, flash point, cloud point and pour point. Results indicate that the biodiesel properties meet the ASTM specifications, validating its suitability as an alternative fuel source. Furthermore, the use of waste cooking oils and eggshell-derived CaO catalyst contributes to environmental sustainability by reducing waste and utilizing renewable resources. This study demonstrates the potential of repurposing waste materials for energy production, offering a viable solution to the challenges posed by fossil fuel dependence.

Keywords

Biodiesel; Eggshell catalyst; Transesterfication; Waste cooking oil; Nanocatalyst

Introduction

There is a vast need for energy in the current world. Since the rise of civilization, the consumption of energy in the world has increased significantly. Readily available and inexpensive fossil energy, concentrated by nature over tens and hundreds of millions of years, enables our current lifestyle and can be conveniently extracted from mines or wells in the earth's crust.

The energy sector is beginning to comprehend the intricate effects and recognize developing possibilities. The two greatest challenges faced by man-kind in this century are the accessibility of energy sources and climate change. The rapid rise in energy demand is a result of the fast-growing population and increasing prosperity. The utilization of energy plays a big role in socio-economic development by improving the standard of living and it is the predominant dependence of human civilization. By 2035, annual energy consumption is predicted to reach approximately 778 Etta Joule, indicating an upward trend in global energy demand projections. The oil and gas industry sector, a major producer and consumer of energy, will face significant challenges. Their limits, exhausting supplies and environmental impact make energy from fossil fuels non-sustainable. About 81.1% of the world's energy supply comes from petrochemical sources such as coal, oil and natural gas, which are used by the majority. Only 18.9% of energy systems are accounted for by nuclear, hydro, bio-fuel and other renewable sources. One day, the world will exhaust its reserves of fossil fuels. Therefore, there is a growing demand for environmentally friendly and sustainable alternative sources. Wind power, hydropower, solar energy, biomass and biofuels are all common forms of renewable energy. Biodiesel could be one of the solutions due to the economic and environmental reasons, highlighting the importance of all these resources' contribution [1-5].

A renewable energy source, biodiesel, derived from the triglycerides of vegetable oils or animal fats, can be used as a substitute for fossil-based diesel fuel and can reduce the drawbacks of diesel emissions. Waste cooking vegetable oils like palm oil, sunflower, soybean, rapeseed, canola oil, corn oil and other feedstock oils like castor oil and animal fats can be used with different types of catalysts and a certain amount of alcohol to produce biodiesel. The phrase Waste Cooking Oil (WCO) refers to edible oil which has formerly been used for frying in restaurants and hotels and no longer be used for similar purpose. In most of the countries, waste cooking oil is simply dumped into the environment [6]. This has major negative effects on the environment, society, the economy and people's health.

There are three solutions for producing biodiesel from used cooking oil: Economic, environmental and waste management. Biodiesel generates no sulphur, no net carbon dioxide, less carbon monoxide, no particulate matter, no smoke and no hydrocarbons when compared to diesel [7]. Biodiesel aids enhanced energy security and balance, less emissions and better air quality, higher engine performance and increased environmental safety.

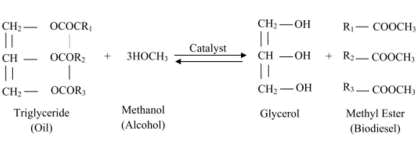

Triglycerides, which are esters of three free fatty acids and glycerol, make up the cooking oils. Alcohol serves as a reactant for the alcoholysis step in the transesterification reaction. During alcoholysis, the alcohol molecule reacts with the triglyceride molecule, leading to the formation of Fatty Acid Alkyl Esters (FAMEs) and glycerol. This process occurs in the presence of a catalyst, typically a base or acid, which facilitates the conversion of triglycerides into biodiesel. Heating is employed to speed up the reaction utilizing a catalyst, as it would otherwise proceed extremely slowly. Sodium hydroxide, potassium hydroxide, sodium methoxide and calcium oxide are typical transesterification catalysts. Homogeneous catalysts are soluble in the same phase as the reactants, resulting in a uniform distribution throughout the reaction mixture. These catalysts typically involve metal ions or complexes, acids or bases in solution. One advantage of homogeneous catalysts is their high catalytic activity and selectivity, as they can interact directly with reactant molecules. However, homogeneous catalysts often suffer from drawbacks such as difficulty in separation and recycling, as they remain dissolved in the reaction medium and require additional purification steps to recover them from the product. Moreover, homogeneous catalysts may pose challenges in terms of environmental impact and waste generation due to the need for solvents and potential catalyst contamination in the final product.

In contrast, heterogeneous catalysts are insoluble in the reaction medium and exist in a different phase from the reactants. These catalysts are typically solid materials with active sites on their surface, such as metal oxides, zeolites or supported metal nanoparticles. Heterogeneous catalysts offer several advantages, including ease of separation from the reaction mixture, enabling their reuse and recycling, which contributes to costeffectiveness and sustainability. Furthermore, heterogeneous catalysts often exhibit higher stability and tolerance to harsh reaction conditions compared to homogeneous catalysts. However, heterogeneous catalysts may suffer from limitations related to mass transfer and surface area accessibility, which can impact their catalytic activity and efficiency. In order to achieve a sustainable alternative to homogeneous catalysts for the generation of biodiesel, heterogeneous catalysts from waste biocatalysts are crucial.

The utilization of Calcium Oxide (CaO) derived from eggshells as a catalyst for biodiesel production is an innovative and promising approach with several notable advantages [8-12]. Eggshells, which are often discarded as waste, contain Calcium Carbonate (CaCO3) as their primary component. Through a thermal decomposition process, CaCO3 can be converted into CaO nanoparticles, which exhibit high catalytic activity due to their abundant surface area and basicity. One significant advantage of using CaO derived from eggshells is its eco-friendliness and sustainability. Eggshell-derived CaO offers a low-cost and readily available alternative to conventional catalysts, making it particularly attractive for small-scale biodiesel production or in regions with limited access to specialized catalysts.

Their high basicity facilitates the conversion of triglycerides into FAME’s by promoting the deprotonation of alcohol molecules and the subsequent attack on triglyceride ester bonds. Moreover, the nanoparticulate nature of CaO enhances its surface area, allowing for increased catalytic activity and efficiency [13-14]. Despite these advantages, there are certain limitations and considerations associated with the use of CaO derived from eggshells as a catalyst for biodiesel production. One challenge is the variability in the composition and quality of eggshells, which may affect the properties and performance of the resulting CaO catalyst. And the synthesis process of CaO nanoparticles from eggshells may require optimization to ensure consistent and reproducible catalyst properties [15].

Methanol is preferable for biodiesel production due to several factors. Methanol is a relatively inexpensive and readily available alcohol, making it economically viable for large-scale biodiesel production. Additionally, methanol has a high reactivity and selectivity in transesterification reactions, leading to high conversion rates and yields of biodiesel. Its low molecular weight also facilitates efficient mixing with the feedstock and catalyst, ensuring uniform reaction kinetics and product distribution.

Moreover, methanol serves as a solvent in the transesterification reaction, aiding in the dissolution of both the triglyceride feedstock and the catalyst. This enhances the interaction between the reactants and the catalyst, promoting the efficiency of the transesterification process. Methanol's solubility properties allow for the removal of excess glycerol and other impurities from the biodiesel product through washing and purification steps.

One significant drawback is the toxicity and flammability of methanol, which poses safety risks to workers and requires careful handling and storage. The production of methanol typically involves fossil fuel-derived feedstock’s and energy-intensive processes, which may offset some of the environmental benefits of biodiesel as a renewable fuel. Efforts to develop sustainable and green alternatives to methanol, such as ethanol or bio based alcohols, are underway to address these concerns and improve the sustainability of biodiesel production processes.

The depletion of fossil fuels and the environmental concerns associated with fossil fuels exhibits the importance of exploring renewable and sustainable alternatives in order to mitigate environmental impact and advance towards a more sustainable energy future.

Materials and Methods

Raw materials

Waste sunflower oil, coconut oil and palm oil were collected from the household which has been used for food frying. The oils were settled for 3-4 days at room temperature, filtered to remove the inorganic residues and food particles and used as a precursor for the biodiesel production. Chicken eggshells were also collected from the household and rinsed with water to remove impurities. These eggshells were sun-dried for a whole day.

Preparation of catalyst

The eggshells were then broken and ground into a fine powder using a porcelain mortar and pestle. The powder was calcined for 5 hours in a muffle furnace at a heating rate of 100°C/min at various temperatures of 500°, 700° and 900°C. The samples were then stored in an airtight container for further characterization. The sample's physical characteristics, including color, smell and tenderness, were investigated and tabulated in Table 1 and a representative image of the sample calcined at 900°C is shown in Figure 1. Calcium Carbonate (CaCO3) gets converted into Calcium Oxide (CaO) during the calcination by the following process (Table 1 and Figure 1).

| Calcination temperature | Duration in hours | Color | Odor | Softness |

|---|---|---|---|---|

| 500°C | 5 | Blackish gray | Slight odor | Hard, flaky |

| 700°C | 5 | Light gray | Slight odor | Hard, flaky |

| 900°C | 5 | Pure white | Odorless | soft |

Table 1: Physical characteristics of the samples of chicken eggshells calcined at different temperatures.

Catalyst characterization

X-ray Diffraction (XRD) analyses of all the synthesized samples were carried out using a PANalytical model diffractometer at a step size of 0.02 with a Cu Kα radiation. Fourier Transform Infrared Spectroscopy was performed using SHIMADZU IRTRACER 100 spectrometer with a wavenumber range of 400 cm-1 and 4000 cm-1 to determine the functional group of the egg shell catalyst. Surface morphology and the elemental composition of the catalysts were observed under a High Resolution Scanning Electron Microscope (HR-SEM) using a FEI-Quanta FEG 200F.

Preparation of biodiesel

Used cooking oils were converted into biodiesel by transesterification process involving an alcohol and a catalyst. 200 ml of used cooking oil was heated to a temperature of 60°C. 50 ml of methanol and 1.1 g of CaO were then added with the oil and continuously stirred at 500 rpm for 45 minutes. To keep track of the reaction temperature, a thermometer was placed inside the beaker. During this step, the transesterification reaction occurs. The transesterification process is given below:

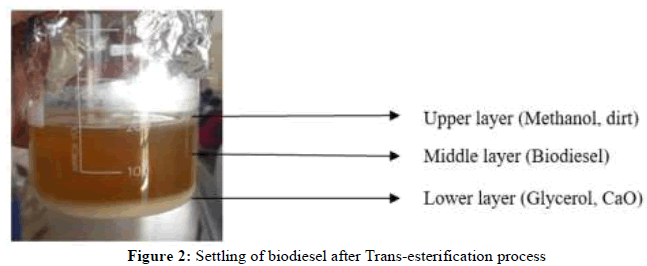

The mixture was allowed to settle for 24 hours after the procedure has been performed. The mixture had three layers as shown in Figure 2. The topmost layer contained the methonal and dirt and the middle layer with biodiesel and the denser bottom layer contained glycerol (by-product of transesterification process) and CaO catalyst. The surplus methanol was removed from the biodiesel after the biodiesel had first been separated from it using a syringe filter. Since glycerol immiscible with biodiesel, it may be conveniently removed using either the settling process or a syringe filter (Figure 2).

After manual separation, residues of CaO, methanol and glycerol may still be present. The unreacted methanol in biodiesel possess a safety issue and has the potential to cause damage to engine parts. Additionally, the biodiesel's glycerol can diminish gasoline lubricity and result in various deposits. Since these unreacted leftover products are water soluble, they can be eliminated by washing them 2 to 3 times in warm distilled water of 50°C-60°C and centrifuged to remove any excess water present in the biodiesel. The products were then stored in containers for further analysis. The biodiesel obtained from used palm oil, sunflower oil and coconut oil are shown in Figure 3.

Biodiesel characterization

The biodiesels obtained from the various waste cooking oils using chicken eggshell catalyst calcined at 900°C were further analyzed in accordance to American Society for Testing and Materials (ASTM) test methods.

Results and Discussion

X-Ray Diffraction Technique (XRD)

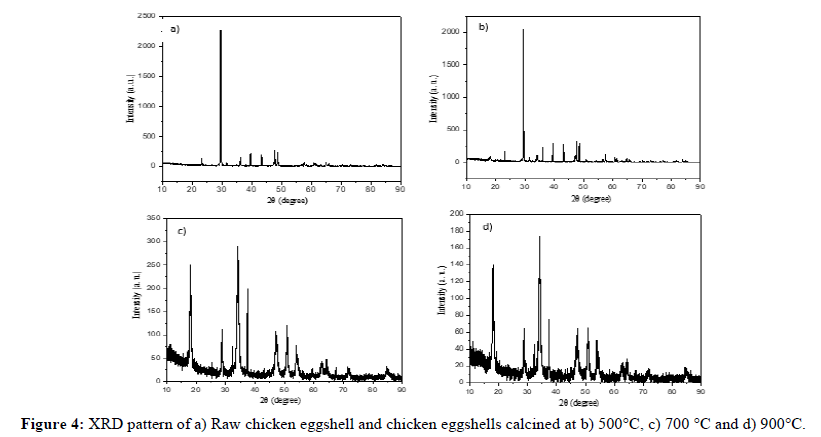

X-ray diffraction patterns of chicken egg shells before calcination and after calcination at 500°C, 700°C and 900°C are shown in Figure 4 respectively. The XRD of the raw eggshells shows a major peak at 2θ equal to 29.59° which corresponds to the Calcite (CaCO3) as a major constituent of the raw egg shell. The pattern matches with the JCPDS card No. 47-1743. The XRD diffraction peaks of the samples calcined at 500°C for 5 hours exhibited peaks characteristic of CaCO3, indicating that calcite remained intact and was not decomposed during the heating process. At a calcination temperature of 700°C, the XRD peak associated with CaCO3 vanished entirely, indicating the decomposition of CaCO3 into CaO. Furthermore, the XRD peaks exhibited increased broadness representing a reduction in particle size. This reduction in particle size is likely attributable to the thermal decomposition process, which results in the formation of smaller CaO nanoparticles. The disappearance of the CaCO3 peak and the broadening of XRD peaks affirms the structural transformation of the eggshell-derived catalyst during calcination, leading to the formation of CaO nanoparticles with enhanced catalytic properties. The XRD peaks of the calcined eggshells can be seen at 2q equal to 28.68°, 34.17°, 37.38°, 47.13°, 50.82°, 53.92°. The XRD peaks of calcined eggshells at 900°C for 5 hours compared with JCPDS card No. 01-077-2010 corresponds to the Calcium Oxide (CaO) or the lime of the face-centered cubic form, with a small amount of calcium hydroxide (Ca(OH))2 of the hexagonal form as a result of the moisture absorption.

The interplanar spacing or the d-spacing was obtained using the relation, dhkl=l/2sinq, where q is the angle of diffraction and l is the X-ray wavelength. The crystalline size of the CaO is found using Debye Scherrer’s formula given by, D=kl/βcosq where D is the crystalline size, k is the Scherrer constant or shape factor, l is the XRD wavelength, β is the Full Width Half Maximum (FWHM) peak intensity and q is the angle of diffraction. The crystallite size of the chicken eggshells calcined at 900°C for 5 hours was calculated to be 43.52 nm (Figure 4).

Fourier Transform Infrared Spectroscopy (FTIR)

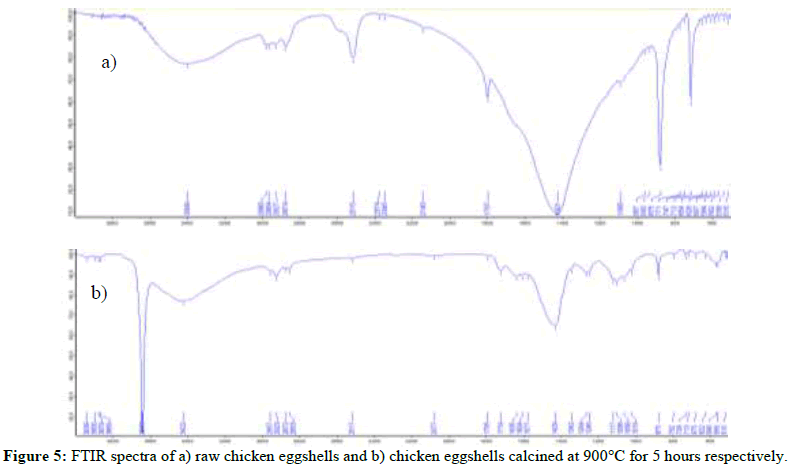

FT-IR analyses were carried out to determine the functional groups present in the sample. The FTIR spectrum of raw chicken eggshells and chicken eggshells calcined at 900°C for 5 hours are shown in Figure 5 a and b respectively. From the FTIR spectra of the raw chicken egg shells, the bands at 875 cm-1, 1421 cm-1, 2515 cm-1 represents the C-O stretching and bending of the CaCO3 which is the main component of the raw eggshell, bands 3399 cm-1 stands for H2O, bands 2874 cm-1 and 1797 cm-1 stand for C=O. The sharp band at 712 cm-1 represents the Ca-O bond. The carbonate, CO3 spectra of raw eggshell and CaO nanoparticles both appear at 875 cm-1. The oxygen atom of the carbonate and calcium in the raw eggshell is shown by the presence of this band. The sharper CaO band at 1429 cm-1 indicates that the carbonization of CaO nanoparticles caused the C-H bond to extend. The O-H bond from moisture on the surface of CaO nanoparticles has caused the adsorption peak at 3643 cm-1. Raw eggshells' sharp band at 654 cm-1 was absent, however it was no longer there since it had already been changed into calcium oxide nanoparticles. The adsorption of moisture and carbon dioxide from the atmosphere was responsible for almost the homogeneity of peaks for both CaO nanoparticles and raw eggshells during the experiment (Figure 5).

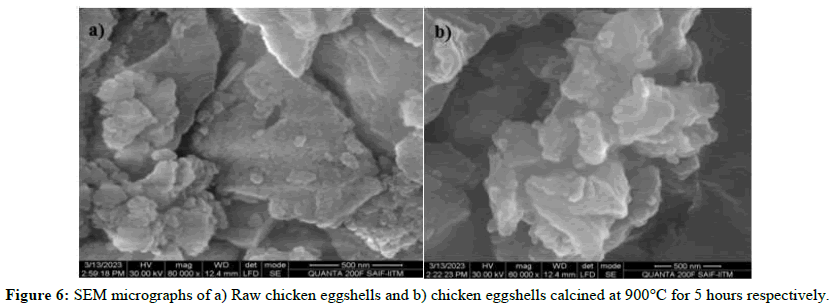

Scanning Electron Microscopy (SEM)

SEM micrographs of raw chicken eggshells and chicken eggshells calcined at 900°C for 5 hours are shown in Figure 6 respectively. The micrographs demonstrate a clear change in the morphology of the catalyst upon calcination. The irregularity in shape of the raw chicken eggshell is modified to a fine structure. The change in morphology is attributed to the change of composition of the eggshell which is the decomposition of Calcium Carbonate (CaCO3) to Calcium Oxide (CaO) and Carbon Dioxide (CO2) thereby decreasing the size of the particles.

Biodiesel characterization

The density, kinematic viscosity, flash point, cloud point and pour point of the synthesized biodiesels from waste cooking oils such as palm oil, sunflower oil and coconut oil were performed as per ASTM standards and are tabulated in Table 2. Measuring the density of biodiesel helps to ensure compliance with quality standards and specifications set by regulatory bodies like ASTM (American Society for Testing and Materials). Density serves as an indicator of biodiesel's purity and suitability for use as a fuel. Moreover, density data are essential for calculating other important fuel properties such as energy content, viscosity and combustion characteristics, which impact engine performance and emissions. The observed density satisfies the ASTM standard value of 820 kg/m3-845 kg/m3 for biodiesel.

Kinematic viscosity of biodiesel is important because it indicates the fluid's resistance to flow, which can affect its performance in engines. A higher viscosity can lead to challenges with fuel injection, combustion and lubrication, potentially impacting engine efficiency and durability. According to ASTM standards, the kinematic viscosity of biodiesel should typically fall within the range of 1.9 to 6.0 centistokes (cSt) at 40°C. The synthesized biodiesels satisfy the ASTM standards.

Cloud point is the temperature at which wax crystals begin to form in the biodiesel, causing it to appear cloudy or hazy. It indicates the lowtemperature operability of the fuel. The standard cloud point for biodiesel is typically around 12°C. Pour point is the lowest temperature at which biodiesel can flow freely without solidifying or becoming too viscous. It reflects the fuel's ability to withstand cold temperatures without causing fuel flow issues. The standard pour point for biodiesel is usually around 9°C. Flash point is the temperature at which biodiesel emits vapors that can ignite when exposed to an open flame or spark. It indicates the fuel's flammability and safety during handling, storage and transportation. The standard flash point for biodiesel is typically above 130°C. It is observed from the Table 2 that the synthesized biodiesels very well satisfy the ASTM standards and is suitable to be used as a fuel (Table 2).

| Type of oil | Palm oil | Sunflower oil | Coconut oil |

|---|---|---|---|

| Density | 836 kg/m3 | 839 kg/m3 | 854 kg/m3 |

| Kinematic viscosity | 3.7735 cSt | 6.434 cSt | 4.62 cSt |

| Flash point | 250°C | 223°C | 213°C |

| Cloud point | 12°C | 3°C | 6°C |

| Pour point | 8°C | 0°C | 6°C |

Table 2: Comparison of physical properties of the biodiesels obtained from used cooking oils.

Thus, results show that the used palm oil, sunflower oil and coconut oil is suitable to produce biodiesel based on its availability, since most of the food shops use these oils for frying and cooking. These oils can be efficiently recycled to produce biodiesel.

Conclusion

The utilization of waste cooking oils and eggshell-derived Calcium Oxide (CaO) catalyst for biodiesel production presents a promising approach towards sustainable energy production. The successful synthesis of biodiesel from sunflower oil, palm oil and coconut oil using the CaO catalyst demonstrates the feasibility of repurposing waste materials for energy generation. The characterized biodiesel meets ASTM standards for key properties, affirming its potential as a viable alternative to fossil diesel fuel. Moreover, the use of waste materials for catalyst synthesis contributes to waste reduction and promotes a circular economy model. Even though biodiesel offers advantages such as renewability, lower emissions and potential waste utilization, petroleum diesel remains widely used due to its compatibility with existing infrastructure and efficiency. Certain of the characteristics of biodiesel are not optimal from the perspective of engine performance, nevertheless, a wide variety of additives are available to change those characteristics.

Author Contributions

The authors express his thanks to VerGo pharma research laboratories Pvt Ltd., for moral support and encouragement. The author also expresses his gratitude towards analytical colleagues of VerGo pharma research laboratories Pvt. limited for providing analytical support.

References

- Tangboriboon N, Kunanuruksapong R, Sirivat A. Mat Sci Poland. 2012; 30: p. 313-322.

- Gashaw A, Teshita A. Int J Renew Sustain. 2014; 3(5): p. 92-98.

- Arifin SF, Arifin SF. Chem Nat Res Eng. 2009.

- Fadhil AB, Dheyab MM, Ahmed KM, et al. Pak J Anal Environ Chem. 2012; 13(1): p. 7.

- Hossain AB, Boyce AN. Bulg J Agric Sci. 2009; 15(4): p. 312-317.

- Thirumarimurugan M, Sivakumar VM, Xavier AM, et al. J. Biosci Biochem Bioinform. 2012; 2(6): p. 441.

- Sukjit T, Punsuvon V. Eur Int J Sci Technol. 2013; 2(7):49-56.

- Shahid EM, Jamal Y, Shah AN, et al. J Technol Qual Manag. 2012; 8(2): p. 91-100.

- Colombo K, Ender L, Barros AA. Egypt J Pet. 2017; 26(2): p. 341-349.

- Maneerung T, Kawi S, Dai Y, et al. Energy Convers Manag. 2016; 123: p. 487-497.

- Yee KF, Kansedo J, Lee KT. Chem Eng Comm. 2010; 197(12): p. 1597-1611.

- Shimada Y, Watanabe Y, Sugihara A, Tominaga Y. J Mol Catal B Enzym. 2002; 17(3-5): p. 133-142.

- Ramachandran K, Suganya T, Gandhi NN, et al. Renew Sustain Energy Rev. 2013; 22: p. 410-418.

- Mekhilef S, Siga S, Saidur R. Renew Sustain Energy Rev. 2011; 15(4): p. 1937-1949.

- Kim HJ, Kang BS, Kim MJ, et al. Catal Today. 2004; 93: p. 315-320.