Research Article - Der Pharma Chemica ( 2018) Volume 10, Issue 3

Studies on Biodiesel Conversion from Seaweed Padina Sp. at Kimaam, Merauke Regency-Southern of Papua

Daniel Lantang*

Laboratory of Microbiology, Department of Biology, Faculty of Mathematics and Natural Sciences, University of Cenderawasih, Jayapura-Indonesia

- *Corresponding Author:

- Daniel Lantang

Laboratory of Microbiology

Department of Biology

Faculty of Mathematics and Natural Sciences

University of Cenderawasih

Jayapura-Indonesia

Abstract

The use of seaweed has other benefits that do not require extensive breeding ground sufficiently in marine waters, the oil content of 30-50% dry weight and serves as an absorber of carbon from the air, thereby reducing the greenhouse effect. The potential of seaweed as the raw material for making biodiesel is also supported by the content of fatty acids contained in seaweed. Biodiesel production from Padina sp. with CaO by using a catalyst named Psammotaea elongata clamshell have been conducted in the Laboratory of Microbiology, University of Cenderawasih. CaO catalyst have made through calcination process at 1000°C for 2 h and characterized by using scanning electron microscopy. Here, we showed that there are two stages, such as the esterification for 2 h and is catalyzed by H2SO4 1.25% with the ratio of oil and methanol 1:6 and transesterification with the ratio of oil and methanol 1:12 with 1% CaO catalyst at 65°C for 5 h, then biodiesel are characterized viscosity 2.0 cSt, density: 0,66 g/ml, acid number: 1.25, saponification: 106.59 mg KOH/g and power fuel: 45-50 sec. Padina sp seaweed oil can be converted to CaO catalyst from Psammotaea elongata clamshell into biodiesel with the percentage of biodiesel produced from one gram of oil amounted to 5.76%.

Keywords

Biodiesel, Esterification, Seaweed Padina sp., SEM, Transesterification, Papua

Introduction

Biodiesel is an alternative fuel which is generally defined as the monoalkyl esters of vegetable oils and animal fats [1]. Seaweed is considered as one of the important material as one of the renewable energy sources to replace fossil fuels because it is easily found and easily cultivated. Development of biodiesel production with raw material seaweed is a breakthrough third generation in maintaining the continuity of supply of raw material for biodiesel, it is because seaweed has the photosynthetic efficiency high so as to produce crops faster, the harvest easier than other vegetable oils [2,3]. The use of seaweed also has other benefits that do not require extensive breeding ground sufficiently in marine waters, the oil content of 30-50% dry weight and serves as an absorber of carbon from the air, thereby reducing the greenhouse effect [4,5]. The potential of seaweed as the raw material for making biodiesel is also supported by the content of fatty acids contained in seaweed. The test results of fatty acids contained in seaweed Dunaliella tertiolecta obtained that contains most of the methyl linoleate and methyl palmitate, these compounds are very well when converted into biodiesel [6].

In general, the catalysts used in the production of biodiesel can be homogeneous and heterogeneous solid catalyst. The use of homogeneous catalysts in biodiesel production has some weakness that is very hygroscopic, corrosive, difficult to separate from the product, and the catalyst cannot be reused. As for the heterogeneous catalysts have the advantages of which are not corrosive, it can be used again, the separation is easily done and friendly to the environment. Heterogeneous catalysts are used in the production of biodiesel include CaO and MgO [7-9].

One of the obstacles encountered in the use of biodiesel is relatively higher price compared with the price of petroleum. This is because the conversion of biodiesel from the oil of seaweed which is reacted with the alcohol with the help of catalysts, both homogeneous and heterogeneous catalysts has a high enough price. Therefore, to overcome these problems, the catalyst to be used can be made from other sources that contain large CaCO3. Some materials that can be used as a source of CaO, include from waste egg shells and clamshell [7]. CaO serves as a catalyst base in biodiesel transesterification reaction. CaO has a high alkaline, low solubility, as well as easy in the process of separation of the product [10], so that they can be reused. Previous research found that the conversion of biodiesel from palm oil by using CaO of a snail shell field is still yielding over 80% to the use of the five [11]. Based on the above, this research is done making biodiesel from seaweed using solid heterogeneous catalysts with the topic "The conversion of biodiesel from seaweed Padina sp. using CaO catalyst from Psammotaea elongate clamshell".

Material and Methods

Samples and materials

Seaweed Padina sp. taken from the village of Kimaam, Merauke regency, Papua Province while clamshell Psammotaea elongata from the village of Okaba, Merauke regency, Papua Province of Indonesia.

Preparation clamshell of Psammotaea elongate

P. elongate clamshell washed with distilled water until clean. Furthermore, the catalyst base material is dried in an oven at 150°C until dry. Catalyst base material of 500 g then crushed until smooth using a mortar and sieved with a ± 200 mesh sieve size [12].

CaO catalyst synthesis of clamshell of P. elongate

P. elongate clamshell solids have been shifted and weighed 100 g. CaO synthesis process of clamshell P. elongate is done by inserting a solid that has weighed into the calcination apparatus. The calcination process is done by heating the solid at temperatures of 1000°C for 2 h. Furthermore, the calcination temperature is lowered to cool the tool and catalyst is inserted into the bottle and sealed to avoid contamination free air [12].

Preparation of seaweed from Padina sp.

A total of 1 Kg of wet seaweed samples taken from the waters of Merauke, Southern Papua, Indonesia, dried by drying in the sun for several days. The sample was then pulverized by means of a blender and fed into an Soxhlet and extracted oil contained therein by using n-hexane solvent. The oil is separated from the solvent using the evaporator.

Oil degumming of Padina sp.

Degumming process is carried out by adding concentrated H2SO4. A total of 0.5 g of oil put into a flask then added 1.5 ml of concentrated sulfuric acid, stirring for 15 min at a temperature of 50ºC. Then the samples allowed to stand for 24 h. Further samples separated from the resin using a separating funnel.

Analysis of free fatty acids

A total of 0.5 g of oil was added to a 100 ml Erlenmeyer flask, add 50 ml of 96% ethanol. Once mixed, add 3 drops of phenolphthalein indicator. Then the solution is titrated with 0.1 M NaOH until the color changes to pink. Stop titration and calculate levels of free fatty acids.

Oil esterification of Padina sp.

Oils derived from seaweed inserted into the tool reflux, then esterified with methanol (Oil and methanol mole ratio of 1: 6) and added with an acid catalyst H2SO4 0.1 M as much as 1.25% by weight of methanol and oils. Mixture is refluxed at a temperature of 65-70°C for 2 h. The reaction mixture is cooled and formed two layers: the upper layer: methanol and methyl esters as well as the bottom layer: triglycerides. The next two layers are separated by using a separating funnel. Results triglycerides used for further processing.

Transesterification of triglycerides from the oil of Padina sp.

Triglycerides that have been separated at the stage of esterification is reacted with methanol (Oil and methanol ratio is 1:12) and added to the base catalyst CaO clamshell P. elongate weighing 1% of the total weight of the oil and methanol. Mix reflux return at a temperature of 65-70°C for 5 h. The reaction mixture is cooled. CaO catalyst is separated from the mixture, then the mixture of methyl ester and glycerol is separated using a separating funnel, and then evaporated methyl ester. Methyl ester was then washed with distilled water repeatedly in a separating funnel, until the last washing colored clear water layer. The final step with the addition of the methyl ester anhydrous Na2SO4, then filtered with filter paper Whatman No. 42. The biodiesel is then tested the acid number, saponification, density, viscosity, and fuel power.

Results and Discussion

Synthesis CaO from P. elongate clamshell

Synthesis process begins with the preparation clamshell of P. elongate. Clamshell washed with distilled water until free of dirt and sea moss, then dried in an oven at 150°C for several hours to remove water and dirt still attached and simplifies the process of grinding. Furthermore clamshell crushed until smooth using a mortar. Thereafter, the solids in the sifter with a 200 mesh sieve. The intended use size 200 mesh sieve in order to reduce the size because the smaller the size, the greater the surface area. The solids are then calcined at the furnace temperature of 1000°C for 2 h. Calcination at high temperatures aiming to remove CO2 from CaCO3 in order to obtain CaO. CaO obtained white with finer structure or shape such as flour. CaO catalyst percentage of P. elongate clamshell through calcination process at a temperature of 1000°C is 55.99%.

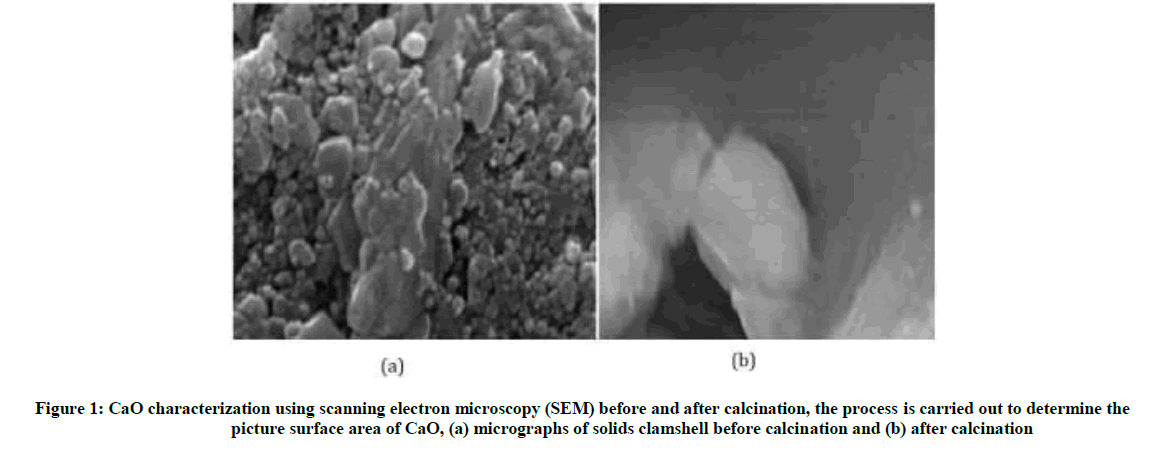

CaO characterization from P. elongate clamshell by Scanning Electron Microscopy (SEM)

CaO characterization by SEM before and after calcination was conducted to determine the surface area of CaO. The results of the SEM micrograph on the solid sample P. elongate clamshell before and after calcination at 30,000 times magnification are as shown in the following Figure 1.

On view micrograph image (a) Shows the porosity much as solids still in the form of CO2 whereas CaCO3 that is contained in the image (b) There is only a single basin. It can be assumed that after calcination the solid clamshell has experienced termination or removal of CO2, so that it can be said that the single basin is CaO.

Analysis of fat content of the Padina sp.

Padina sp. oil can be obtained by extracting the seaweed using Soxhlet extraction method. Synthesis begins with sample preparation includes washing, rinsing, drying and grinding the sample. Padina sp. has thallus surface there is calcification, thus washing and rinsing is done with the aim to remove impurities or sea moss and cleaning thallus of the remnants of chalk attached.

The drying process aims to avoid the decay process and facilitates the extraction process. To reduce the water content, the samples were dried by drying directly in the sun. This method is used for drying by using an oven resulting in quality seaweed to decrease, but it is also not perfect drying. Extraction is done in the rest of the dried leaves produce more than the fresh leaves, because the water content is inversely related to fat content. If the water level is high then low fat content, and vice versa, and therefore seaweed drying is done until completely dry. It is characterized by a color change from yellowish brown to brown dark and stiff and crumbly texture when grasped. Further samples of crushed with the crusher and used as flour seaweed, then wrapped with filter paper to extract the oil.

Soxhlet extraction is done by using an organic solvent which has a low boiling point. n-Hexane very non-polar so it is often used in the extraction of fats or oils since this solvent has a constant low at 1.89. Dielectrum constants declared repel force between two electrically charged particles in a molecule. The higher the constants dielektrum a solvent so that the solvent is more polar [13]. Extraction is done for approximately 4-6 h or until color solvent cleared. Oil is then separated from the solvent by means evaporated. The percentage of oil produced from ± 1 g flour seaweed was 12.4%.

Factors affecting the composition of the oil content in seaweed include growing medium and environment where the sea grass grows. An example of the type of seaweed that contains carbohydrate and high fat is namely Chlorella sp., [14].

Synthesis of biodiesel by esterification of oil Padina sp.

The content of Free Fatty Acid (FFA) is one of the deciding factors in the process of making biodiesel. Esterification process with acid catalyst is needed if oil were to be used as a raw material has FFA content above 5%. If oil high FFA levels (> 5%) directly transesterified with a base catalyst, the FFA will react with the catalyst to form soap. The calculated value of the content of FFAs in the oil seaweed is 11.47%. So that should be a two-stage reaction is esterification and transesterification.

Transesterification of triglyceride oils of Padina sp.

Transesterification of triglyceride oils Padina sp. carried out after the esterification reaction. Transesterification reaction carried out by reacting Padina sp. oil triglycerides and methanol with a mole ratio of 1:12 and added alkaline catalyst CaO shell P. elongata calcined at temperatures of 1000°C as much as 1% of the total weight of the oil and methanol, for 5 h at a temperature of 65-70°C. The reaction mixture is then cooled. The results obtained are then separated with a separating funnel. Biodiesel evaporation process is then performed to remove the remaining methanol. Biodiesel is done leaching process by using distilled water until the bottom layer of translucent color. Results laundering consists of two layers, namely the top layer and bottom layer in the form of biodiesel is distilled water and residual glycerol. A layer of biodiesel is above because the density of water is greater than biodiesel. Once the biodiesel is separated and distilled water, then given anhydrous Na2SO4 which serves to bind the remnants of the water that is still contained in biodiesel. Then filtered using Whatman No. 40 filter paper in the form of pure biodiesel. Separation yield and subsequent testing acid number, saponification, density, viscosity and power fuel.

Characterization of biodiesel (Table 1)

| Parameter test | Results | ASTM* |

|---|---|---|

| Acid numbers | 1.25 mg KOH/g | 0.8 mg KOH/g |

| Saponification numbers | 106.59 mg KOH/g | £ 261.26 mg KOH/g |

| Density | 0.66 g/ml | 0.86-0.90 g/ml |

| Viscosity | 2.0 cSt | 1.9-6.0 cSt |

| Fuel power | 45-50 sec/ml | - |

*American Society for Testing and Material (ASTM)

Table 1: Characterization of biodiesel

Acid numbers

The acid number of the biodiesel results Padina sp., seaweed is 1.25. Seaweed oil with high acid number can not be used directly as a fuel because it has a FFA that is corrosion. Based on the biodiesel standard ASTM D-6751, which is acid number ranges from 0.8 mg KOH/gr. So it could be said that the acid number of the biodiesel produced from oil Padina sp., has the distinction of great value to the value of the acid number in accordance with ASTM standards.

Saponification numbers

Saponification shows the ability of material containing FFAs and fatty acids which are bound in glycerides react with bases into soap. Weighing 1 g sample is weighed and put into a three-neck flask is then added as much as 1.25 ml of ethanol and 10 ml KOH 0.5 N. The mixture was refluxed for 1 h, the reaction product is cooled. Next add as much as 1-2 drops of phenolphthalein indicator are then titrated with HCl until the pink color just disappeared. Saponification numbers seaweed oil obtained by 106.59 mg KOH/g. ASTM standards for biodiesel saponification number is ≤ 261.26. This indicates that the seaweed oil containing glycerides and small free fatty acid, so it is good to use.

Density

Density is the weight per unit volume of biodiesel. This process is the other important properties of biodiesel. Fuel injectors working on volume size basis, so that if a greater density will lead to the greater mass that was injected. The density of biodiesel will increase with increasing number of double bonds and the reduced length of the chain [15]. Seaweed oil density is 0.66 g/ml, it indicates that the density of biodiesel seaweed approached the density of biodiesel in accordance with ASTM standard is 0.86 to 0.90 g/ml.

Viscosity

Viscosity showed resistance to the fluid flow gravity conditions. Kinematic viscosity equal to the dynamic viscosity or density. This parameter is a basic design specification for fuel injectors used in diesel engines [16]. Viscosity is the most important properties of biodiesel because it affects the operation of the fuel injection equipment, especially at low temperatures while the increase in viscosity affects the fluidity of the fuel. Biodiesel has a viscosity approaching diesel fuel. When the high viscosity, the injector will not work well [16,17], the viscosity of biodiesel from seaweed Padina sp., is 2.0 cSt it indicates that the oil biodiesel Padina sp., fulfill the ASTM standard that is 1.9 to 6.0 and SNI, i.e., 2.3 to 6.0.

Fuel power

Power fuel is a parameter that is used to test the ability of the length of the burning biodiesel. Biodiesel produced from seaweed Padina sp., inserted into the bottle containing the axis test was then burned. The flame of biodiesel is reddish yellow and lit for 45-50 sec with the amount of biodiesel used is 0.5 ml. The following figure shows a large flame when the wick burned, but did not last long. One of the factors that influence the amount of biodiesel used is too little. This is because the fuel for power testing, done only to prove that biodiesel produced is able to burn and how long it takes to light up.

Conclusion

Padina sp seaweed oil can be converted to CaO catalyst from P. elongata clamshell that taken from village of Kimaam, Merauke regency, southern of Papua Province, into biodiesel with the percentage of biodiesel produced from one gram of oil amounted to 5.76%. Characterization of biodiesel from oil seaweed Padina sp., catalyzed by CaO shell P. elongata include acid value of 1.25 mg KOH/g, saponification number 106.59 mg KOH/g, the density of 0.66 g/cm3, viscosity of 2.0 cSt and long burning biodiesel fuel or power 45-50 seconds. While the flow of further research this study is to perform a variation of catalyst CaO shell P. elongata in the manufacture of biodiesel from oil seaweed and needed further characterization that includes GC-MS, cetane number, pour point, flash point, iodine, water content, carbon footprint, as well as the characterization of fuels that meet the standards of ISO/SI (Standard of Indonesian) and ASTM (American Society for Testing and Material).

References

- J. Van Gerpen, Fuel Process. Technol., 2005, 86, 1097-1107.

- T. Minowa, A.Y. Yokoyama, M. Kishimoto, T. dan Okakurat, Fuel., 1995, 74(12), 1735-1738.

- M. Balat, H. dan Balat, Appl. Energy., 2010, 87, 1815-1835.

- T.M. Mata, A.A. Martins, N.S. dan Caetano, Renew. Sust. Energy Rev., 2010, 14, 217-232.

- G. Huang, F. Chen, D. Wei, X. Zhang, G. dan Chen, Appl. Energy., 2010, 87, 38-46.

- H. Tang, N.J. Abunasser, M.E. Danton Garica Perez, M. Chen, S.O. Salley, K.Y. Simon Ng, Appl. Energy., 2011, 88(10), 3324-3330.

- N. Empikul, P. Krasae, B. Puttasawat, B. Yoosuk, N. Chollacoop, K. dan Faungnawakij, Bioresource Technol., 2010, 101, 3765-3767.

- Y.C.D. Leung, W. Xuan, M.K.W. dan Leung, Appl. Energy., 2009.

- X. Liu, H. He, Y. Wang, S. Zhu, X. dan Piao, Fuel.,2008, 87, 216-221.

- C. Reddy, V. Reddy, R. Oshel, J.G. Verkade, Energy and Fuels., 2006, 20, 1310-1314.

- H.S. Prasetyo, Y.Y. Margaretha, A. Ayucitra, S. Ismadji, Proceedings of the National Seminar on Fundamentals and Applications of Chemical Engineering, 2011.

- F. Ma, M.A. dan Hanna, Bioresource Technology., 1999, 70, 1-15.

- S. Sudarmadji, B. Haryono, Suhardi, Liberty, Yogyakarta, 1989.

- M. Mittelbach, C. Remschmidt, Biodiesel: The Comprehensive Handbook., 2004.

- J. Van Gerpen, B. Shanks, R. dan Pruszko, National Renewable Energy Laboratory, Collarado., 2004,

- S.A. Basha, K.R. Gopal, S. dan Jebaraj, J. Renew. Sustain. Energy Rev., 2009, 13, 1628-1634.

- Hikmah, M. N. dan Zuliyana, Universitas Diponegoro, Semarang, 2010.