Review Article - Der Pharma Chemica ( 2024) Volume 16, Issue 6

Review on: Co-Processing of Excipients

Prayuti V. Thete*, M. A. Channawar and A. V. ChandewarPrayuti V. Thete, Department of Chemistry, Pataldhamal Wadhwani College of Pharmacy, Yavatma, India, Email: prayuti261999@gmail.com

Received: 23-Nov-2024, Manuscript No. DPC-23-120857; Editor assigned: 28-Nov-2024, Pre QC No. DPC-23-120857 (PQ); Reviewed: 12-Nov-2024, QC No. DPC-23-120857; Revised: 01-Dec-2024, Manuscript No. DPC-23-120857 (R); Published: 29-Dec-2024, DOI: 10.4172/0975-413X.16.6.504-508

Abstract

Co-processed excipients were prepared by incorporating one excipient into the particle structure of another and a combination of two or more compendial or non compendial excipients to physically modify their properties, which cannot be achievable by simple physical mixing. The co-processed multicomponent-based excipients were introduced to achieve better characteristics and tableting properties. The developed co-processed excipient can be used by the pharmaceutical industry in the future to compound tablets in a fast and economical way.

Keywords

Co-processed; Excipient; Tablet; Multicomponent

Introduction

The pharmaceutical scientist is always on the lookout for newer methods and constituents or excipients that will give a better result in this shot for easier and cheaper methods of formulation. It is important that these newer formulation components do not alter the desired features of the formulation e.g. drug release profile, bioavailability, clinical effectiveness, etc. In the formulation of tablets, the drug and ingredients will need to undergo granulation process to convert them into a state that can be readily compressed into acceptable tablets. Still, Direct Compression (DC) method of tablet manufacture can be used if these formulation components have the necessary degree of fluidity and compressibility.

A crucial element in the DC (Direct Compression) process is the excipients. They must not only possess those properties which are necessary for satisfactory tablet formulation but retain them when mixed together especially with the active ingredients Excipients provide a wide variety of functionalities such as better processibility of different active pharmaceutical ingredients into dosage forms, better tablet binding, better tablet disintegration and more active pharmaceutical constituents bioavailability [1,2].

Literature Review

What is co-processing

The pharmaceutical industry first started to use co-processed excipients from the late 1980’s, with early examples including co-processed microcrystalline cellulose and calcium carbonate, introduced in 1988. The International Pharmaceutical Excipients Council (IPEC) defines excipient as “substances other than the API which have been meetly estimated for safety and are intentionally included in a drug delivery system”. An excipient that has experienced co-processing is a combination of two or further compendial or non-compendial excipients with the goal of physically changing their properties without altering chemical properties [3].

Need of co-processing

Major challenge for tablets and capsule manufacturing comes from the flow properties of the materials to be compressed most of the formulations (>70%) contain excipients at higher concentration than active drug. In recent times drug formulation scientists have recognized that single-component excipients do not always provide the requisite performance to allow certain active pharmaceutical ingredients to be formulated or manufactured adequately. Hence, there is a need to have excipients with multiple characteristics built into them such as better flow, low/no moisture sensitivity, superior compressibility and rapid disintegration capability. One similar approach for improving the functionality of excipients is co-processing of two or more excipients.

Advantages of co-processed excipients

• Enhance the flow qualities.

• Increasing compressibility.

• Increased potential for dilution.

• Lessen sensitivity of the lubricant.

• One excipient can serve numerous purposes.

• Overcome the excipients limitations.

• Advanced organoleptic qualities.

• Displays constructive interaction.

• Improved physiochemical characteristics.

• Minimizes variations to the profile of dissolution.

• Enhanced palatability and increased tongue feel.

• Reduce unfavorable characteristics.

Disadvantages of co-processed excipients

• Elevated temperature enprocessing and specialized filling equipment are needed.

• Pre-clinical species do not always tolerate some lipidic excipients well.

• Cost of process is high due to labour costs, space costs, time, energy and specialized equipment needs.

• Material loss throughout different processing phases.

• Drugs that are thermolabile or humidity sensitive are not suitable candidates.

• Long duration.

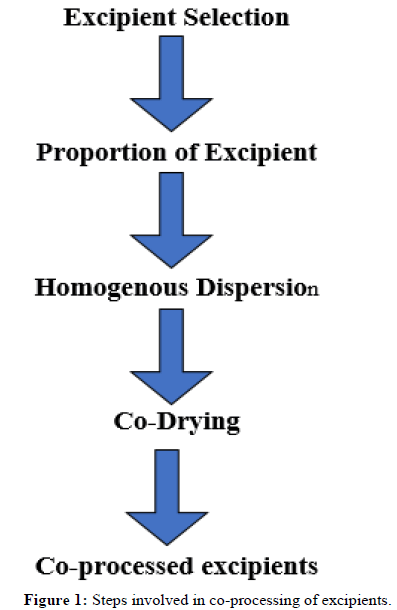

Steps involved in co-processing of excipients

• Selection of the excipients group to be co processed by precisely studying the material (elastic, plastic or brittle) characteristics and functionality requirements.

• Choose needed proportions of excipients.

• Examine the particle size required for co processing.

• Choose a suitable drying method, such as spray drying or flash drying (Figure 1).

Methods of co-processing

• Spray drying

• Wet granulation

• Melt extrusion

• Granulation

• Solvent evaporation

• Crystallization

• Roller drying

• Hot melt extrusion

• Co-transformation

• Milling

Discussion

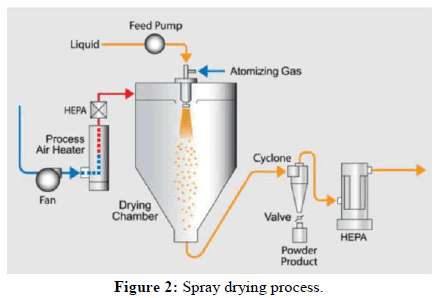

Spray drying

Spray drying is a generally used co-processing technique in the development of new pharmaceutical excipients, as it provides agglomerate or spherical particles with a narrow size distribution, therefore promoting the flow ability of materials. This technique is easy to reproduce and allows good control of particle size [4]. The spray-drying process consists of overlapping stages, involving feed atomization, air-spray contact, liquid evaporation and solid separation (powder collection). The liquid solution, suspension or emulsion is pumped from the feed container to the drying chamber through an atomization nozzle. Water is the preferred vehicle (solvent, dispersion medium) due to safety and cost considerations. For poorly water-soluble drugs and excipients, the use of organic solvents/co solvents or an aqueous suspension is the alternative approach. Several types of atomizers are available including centrifugal (rotary disk), pneumatic (two-fluid), pressure and ultrasonic nozzles. Energy applied during atomization transforms the liquid into fine droplets that are subjected to heated air or inert gas in the drying chamber. The high surface area of the droplets helps rapid drying by effective heat and mass transfer [5].

Advantages of spray drying

• Continuous and easy to control process.

• Rapid and non-contact draying.

• The droplets are small.

• Applicable to toxic and explosive materials.

• Good properties for the spray-dried powder so it can be easily compressed into the form of material.

• Labor cost is low since the materials is dried in single operation without handling.

Disadvantages of spray drying

• Spray dryer is bulky and also expensive to install.

• It is difficult to clean after use.

• It has a low thermal efficiency that is a lot of heat is wasted during operation.

• Solid materials cannot be dried using spray dryers.

• Product degradation or fire hazard may result from product deposit on the drying chamber (Figure 2).

Wet granulation

Co-processing of excipients using wet granulation technique simply involve wet massing of the blend of the excipients to be co-processed with a granulating liquid, wet sizing, drying and then screening of dry granules. Wet granulation is a cost effective method of co-processing as it can be adopted for conventional equipment like a planetary mixer/high shear mixer and requires validation of fewer process variables [6].

Melt extrusion

The blend of excipient is mixed with a melt able binder (typically at solid below 80°C). The mixture is subjected to heat above the melting point of the binder with continuous blending in order to break the mass into agglomerates. The cooled agglomerates are eventually screened to obtain granules with desired size [6,7].

Solvent evaporation

This process is carried out in a liquid manufacturing vehicle. The coating excipient is dissolved in a volatile solvent. Which is immiscible with the liquid manufacturing vehicle phase. A core excipient material to be microencapsulated is dissolved or dispersed in the coating polymer solution. With agitation, the core coating material mixture is dispersed in the liquid manufacturing vehicle phase to obtain the proper size microcapsule. The mixture is then heated (if necessary) to evaporate the solvent. Once all the solvent is evaporated, the liquid vehicle temperature is reduced to ambient temperature (if needed) with continued agitation. At this stage, the microcapsules can be used in suspension form, coated on to substrates or isolated as powders. The core materials may be either water-soluble or water insoluble materials.

Crystallization

Crystallization is the natural or artificial process of formation of solid crystals precipitating from a solution, melted or further infrequently deposited directly from a gas. Crystallization is also a chemical solid-liquid separation technique, in which mass transfer of a solute from the liquid solution to a pure solid crystalline phase occurs. Procedure for crystallization to occur from a solution it must be supersaturated. This means that the solution must hold more solute entities dissolved than it would have under the equilibrium. This can be achieved by various methods, with solution cooling, Addition of a second solvent to reduce the solubility of the solute (technique known as anti-solvent or drown out). Chemical reaction changes in pH being the most common methods used in industrial practice [8].

Roller drying

A roller dryer is used to dry the homogeneous solution or dispersion containing the pre-blended excipients. Meggelaars, et al., applied this technique to co-process lactose with sorbitol and lactitol. The temperature used was sufficiently high to gain a product that consists basically of B-lactose in crystalline form [9].

Hot melt extrusion

Hot melt extrusion uses heat with a temperature greater than 80°C. This method is not suitable for thermo labile materials. The excipients are melted and also pressurized through the die and solidify into a variety of shapes. The solvent is not needed in the process as the molten polymer can function as a thermal binder [9,10].

| Co-processed excipients | Trade name | Advantages |

|---|---|---|

| Microcrystalline cellulose, colloidal silicon dioxide | Dicom sanaq sp206 | Used in direct compression of hygroscopic and moisture sensitive apis and has excellent flow properties. |

| Mannitol, hydroxypropyl, methylcellulose | Pearlitol | Used in direct compression of controlled oral tablets, binder. |

| Hypromellose and lactose | RetaLac® | Improved flow and bendability, enhancing compatibility in direct compression. |

| Calcium carbonate and polyvinyl pyrrolidone | Dicom-dc® S-604 | Excellent Flowability, better compressibility and uniform particle size distribution. |

| Lactose and cellulose | Cellactose | High compressibility, good mouth feels, better tableting at low cost. |

| Sucrose and dextrin | Dipac | Directly compressible grade. |

| Calcium carbonate and sorbitol | Formaxx | High compressibility, excellent taste masking, free flow, superior content uniformity, controlled particle size distribution. |

| Lactose and maize starch | Starlac | Good flowability due to spray drying the acceptable crushing force due to lactose content and rapid disintegration. |

| Microcrystalline cellulose and guar gum | Avicel ce-15 | Less grittiness and minimal chalkiness. |

| Carmellose crospovidone, mannitol, microcrystalline cellulose | Granfiller-d | Direct compression odts, high tablet hardness and rapid disintegration. |

| Microcrystalline cellulose and lactose | Microcelac | Capable of formulating high dose, small tablets with Poorly flowable active ingredients. |

Table 1: Commercially available co-processed excipients used in direct compression.

Co-transformation

Co-transformation technique involves the operation of heat or solvent effect to “open-up” that is for swelling the particle of one excipient. The other excipients are incorporated into the “opened-up” structure of the aforementioned excipient. The augmented excipient strengthens the functionality of the end product.

Milling

A roller mill, ball bill, bead mill, millstone mill, jet mill or a hammer mill can be used to perform milling or dry grinding, the excipients are premixed and passed through a high-speed milling machine. During the process of milling, the particles meet each other and form bonds when they are subjected to force to mill or pass through the screen (Table 1) [10].

Evaluation method of co-processed excipients

There are various ways to test the co-processed excipients such as angle of repose, Hausner ratio, Carr’s index, sieve analysis, friability test, swelling index and loss on drying. There are three common methods to determine the flowability namely angle of repose, Hausner ratio and Carr’s index.

Applications of co-processed excipients

• In ongoing years, new applications have been distinguished for a few existing excipients. A significant number of these excipients are utilized either alone or in mix as mono or multifunctional excipients in controlled medication conveyance frameworks. They are monetarily more gainful than the new concoction substances. Some of them are, chitosan, thickener, guar gum, poly (DL-Lactic corrosive), polyox water dissolvable tars.

• The co-processed calcium carbonate/microcrystalline tablet excipients of this creation are principally planned for use in nutrient caplets, in spite of the fact that they may discover utility in numerous sorts of compacted tablets.

• Direct pressure process.

• Callactose utilized in high measurements tablets, home grown details.

• Used in chewable, bubbly tablets. E.g. pearlitol SD with mannitol.

• Diluent for containers.

• In adjusted discharge definition. For example, Ludipress.

• Co-processed excipients were structured with an expect to forces great stream properties, direct pressure qualities, appropriateness for various water insoluble medications (BCS Class II) and with discharge retardant attributes to acquire continued discharge sedate conveyance frameworks.

• It can be presumed that the readied novel co-processed details can be appropriately utilized for planning continued discharge definition of various BCS class II drugs. The tablets can be legitimately packed with fuse of least 50% W/W of medication alone (or sedate alongside different excipients) and an all-inclusive medication discharge for 12 hours might be acquired.

Conclusion

Most of the SMEs do not possess optimal multifunctional properties like flow, compressibility, compatibility and disintegration ability, required to compensate for poorly compactable drugs. Some of these drawbacks can be overcome by co-processing of SMEs with polymers. For example, co-processing of a brittle SME and plastic material (polymer) can provide a synergistic effect and result in the generation of single entity multi-functional excipient. Besides, novel co-processed excipients generated using combinations of SMEs and polymers can also generate intellectual property rights.

References

- Myrdal PB, Sheth P, Stein SW. Aaps Pharmscitech. 2014; 15: p. 434-55.

[Crossref] [Google Scholar] [PubMed]

- Builders PF, Bonaventure AM, Tiwalade A, et al. Int J Pharm. 2010; 388(1-2): p. 159-167.

[Crossref] [Google Scholar] [PubMed]

- Bhavana P, Reddy MS. GSC Biol Pharm Sci. 2023; 23(1): p. 212-219.

- SB S, Aute S, Deshpande R. Manipal J Pharm Sci. 2019; 5(2): p. 5.

- Al-Zoubi N, Gharaibeh S, Aljaberi A, et al. Processes. 2021; 9: p. 267.

- Gohel MC, Jogani PD, Bariya SH. Pharm Devel Technol. 2003; 8(2): p. 143-151.

[Crossref] [Google Scholar] [PubMed]

- Chaudhari PD, Phatak AA, Desai U. Int J Pharm Chem Sci. 2012; 1(4): p. 1480-1498.

- Binab KA, Gaurav A, Mandal UK. Int J Pharm Pharm Sci. 2019; 11(1): p. 1-9.

- Bin LK, Hui HS, Uddin AH, et al. J Pharm Negat Results. 2022: p. 96-103.

- Sumit Marathe, Vipul Pate. JETIR. 2020; 7(3): p. 1723-1738.