Research Article - Der Pharma Chemica ( 2018) Volume 10, Issue 5

Reuse of Immobilized Candida cylindracea Lipase in Sugar Ester Synthesis and Influence of Different Solvents in Lipase Activity

Nacer Rezgui, Fatma Loulou, Nadia Bouzaouit and Chahra Bidjou-Haiour*

LOMOP, Organic Synthesis and Modeling Group, Faculty of Sciences, Badji-Mokhtar University, BP 12 El-Hadjar, 23000 Annaba, Algeria

- *Corresponding Author:

- Chahra Bidjou-Haiour

LOMOP, Organic Synthesis and Modeling Group

Faculty of Sciences

Badji-Mokhtar University

BP 12 El-Hadjar, 23000 Annaba, Algeria

Abstract

Candida cylindracea lipase was immobilized onto celite and used for the first time as an efficient biocatalyst for sugar ester synthesis. In the present work we examined the catalytic behavior and the reusability of the immobilized lipase for glucose laurate synthesis in organic media. The effect of the use of solvents with different polarity (Butanol, diethyl ether, methanol and hexane) to wash the immobilized lipase before the enzyme reuse was evaluated. The biocatalyst was incubated at 25°C in these four solvents. The washing with Butanol allowed the highest catalytic activity (94%) after one cycle of the biocatalyst reuse. The obtained results suggest that immobilized C. cylindracea lipase prepared from the free enzyme by adsorption on a solid support can become a powerful biocatalyst for sugar ester synthesis with the same performances than those currently available.

Keywords

Lipase, Immobilization, Reuse, Organic solvents, Polarity, Activity

Introduction

Candida cylindracea lipase (CCL) has proven to be a versatile catalyst for a wide range of biotransformations [1,2]. Immobilization of lipases on appropriate solid supports [3] is one way to improve their stability and activity and facilitates their recovery from the product mixture in order to reuse the biocatalyst for several reaction cycles [4,5]. Celite®545, a low-cost support with large surface area has been of greatest interest for CCL immobilization [6,7]. The free lipase was physically immobilized onto celite by simple adsorption to give the immobilized C. cylindracea Lipase (CCL I). In our previous work and by attachment of CCL onto solid supports, enhanced enzyme activity and stability was achieved compared to the native enzyme [8].

In this work, the lipase-catalyzed esterification of D-Glucose with Lauric acid was selected as a model reaction to investigate the effect of the immobilized lipase reuse [9]. Indeed, sugar esters are non-ionic surfactants and are mainly used in food, cosmetics, pharmaceutical and detergent applications [10,11]. The immobilized enzyme can be easily recovered from the reactional medium allowing its reuse. The use of four solvents (Butanol, diethyl ether, methanol and hexane) to wash the lipases and the influence of solvent structure on the activity and stability of immobilized C. cylindracea lipase were studied. In this lipase-recycling system, the immobilized lipase was reused with a less loss of activity. However, the effect of solvent structure on the stability of CCL I has not been extensively studied so far. The operational and thermal stabilities of the lipase were also compared with those of the native enzyme.

Materials and Methods

C. cylindracea a commercial lipase (CCL) was purchased from Sigma Co. Glucose (Sigma-Aldrich), Lauric acid and celite (0.2-0.5 mm) from Merck were tested as starting materials. Other chemicals used were of analytical grade.

Lipase immobilization

Celite (60 mg) was added to 10 ml of 0.1 M phosphate buffer (pH = 8) containing C. cylindracea lipase (100 U/ml). The reaction was then stirred with a magnetic bar at 4ºC and 100 rpm for 0.5 h. 20 ml of cold acetone were then added. After 2 h, the suspension was filtered. The immobilized enzyme was washed with acetone, dried in a vacuum desiccator and then stored at -18ºC.

Lipase-catalyzed esterification

D-Glucose (200 mg) was first dissolved in one volume of ethyl methyl ketone for one night. After that, the acyl donor was added, the mixture equilibrated for 15 min and the biocatalyst finally incorporated. Aliquots were removed at intervals, filtered and analyzed qualitatively by thin layer chromatography and quantitatively by volumetric titration.

Analysis

The sugar content was quantified by calculating the residual fatty acid amount in the reaction mixture. Samples were analyzed by volumetric method: 0.1 g of sample of reaction mixture was diluted in 20 ml of 0.1 wt% phenolphthalein solution in absolute ethanol and then titrated with standardized sodium hydroxide solution of 0.1 M in water [12].

Reuse of the lipase: Treatment of CCL I with the solvents

The immobilized lipase (0.1 g) was incubated in 10 ml of the solvents (Butanol, acetone, diethyl ether, methanol and hexane) during 10 min at 25°C and magnetically stirred. After that, the lipase was filtered under vacuum, washed with the appropriate solvent, dried at 40°C and stored in a vacuum desiccator. The enzyme was then reused in a new cycle.

Results and Discussion

Glucose-lauric acid ester production catalyzed by immobilized CCL I offers the possibility of easy reuse of the biocatalyst, which is very important to minimize costs and to make this process economically feasible. The effect of the solvents used for lipase washing (Butanol, diethyl ether, methanol and hexane) on the esterification activity of CCL I was studied.

Glucose laurate ester Synthesis

Preparation of CCL I [13] was conducted using celite and free CCL. Although the CCL I was insoluble in the organic solvents, the lipase was protected and worked effectively as a biocatalyst [14].

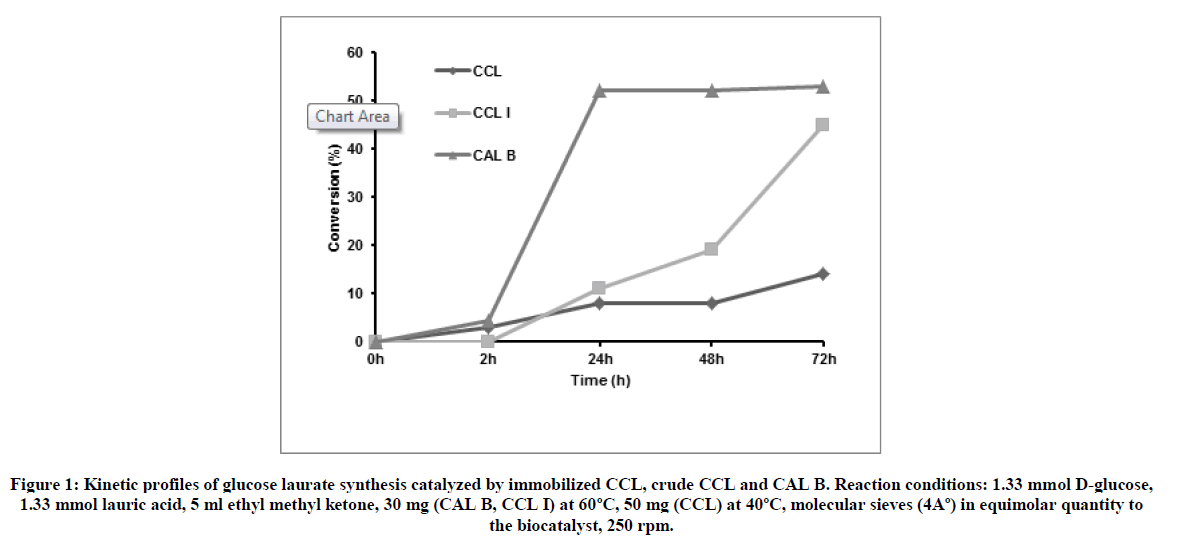

The esterification of glucose by Lauric acid induced by the prepared CCL I, unmodified lipase CCL, and an immobilized commercial lipase from Candida antarctica CAL B [15,16] were compared in Figure 1.

Figure 1: Kinetic profiles of glucose laurate synthesis catalyzed by immobilized CCL, crude CCL and CAL B. Reaction conditions: 1.33 mmol D-glucose, 1.33 mmol lauric acid, 5 ml ethyl methyl ketone, 30 mg (CAL B, CCL I) at 60ºC, 50 mg (CCL) at 40ºC, molecular sieves (4Aº) in equimolar quantity to the biocatalyst, 250 rpm.

Results in Figure 1 show that the conversion obtained with the immobilized lipase (45%) is higher than that of the free one and closer to that obtained with CAL B (52%). After immobilization, CCL I exhibited improved thermal and operational stabilities.

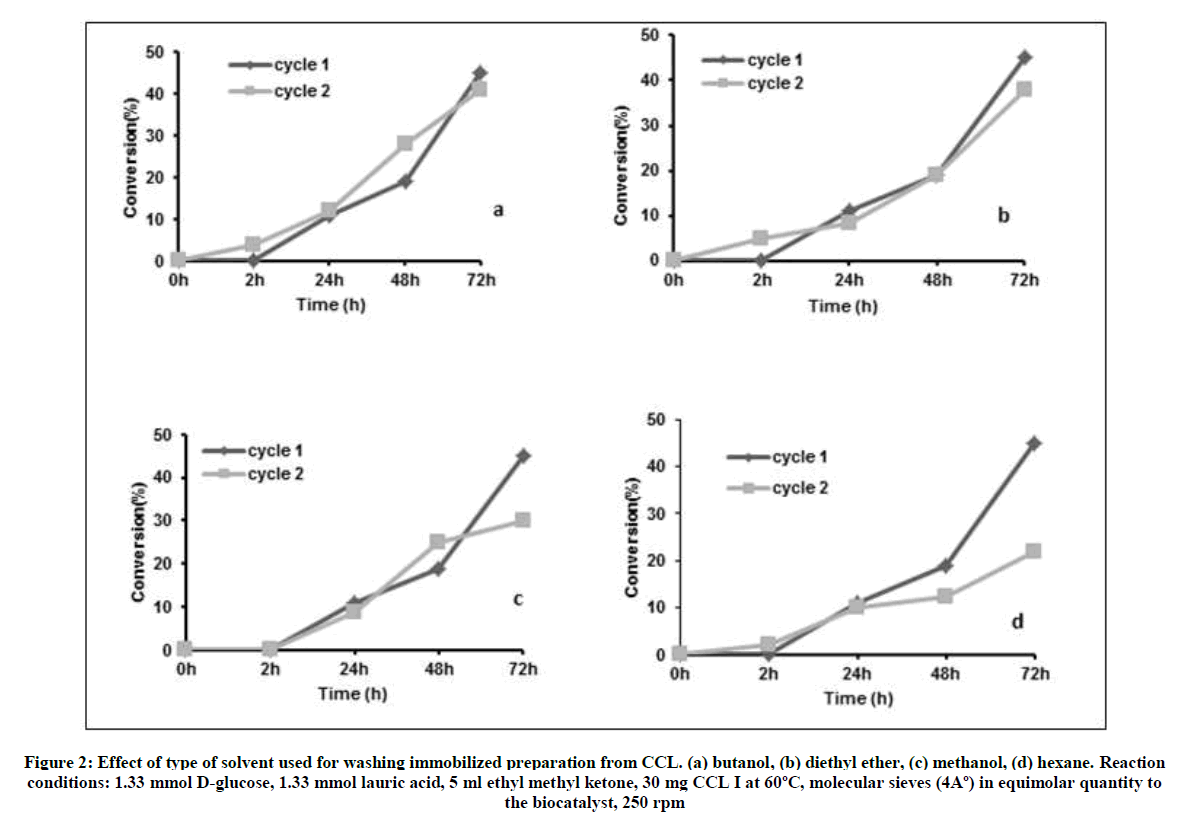

Biocatalyst reuse with solvent washing

In order to improve the reusability of the immobilized biocatalyst, CCL I was washed with butanol, diethyl ether, methanol and hexane before its reuse. Figure 2 shows the conversions attained after the lipase washing with the four solvents. According to this figure, the relative fatty acid conversion attained with butanol (Figure 2a) and diethyl ether (Figure 2b) was higher than the two other solvents. After washing with butanol and diethyl ether, the conversions were around 40% for both solvents. For the washing with methanol (Figure 2c), the conversion obtained was 30%. After washing with hexane (Figure 2d), the conversion was only 22%. These results can be attributed to a more or less better lauric acid (unreacted) removal adsorbed on the lipase support by the solvents. Therefore, solvent washing of immobilized CCL has been tested and the lauric acid solubility was analyzed (Table 1). The results showed that butanol and diethyl ether allowed higher lauric acid removal than methanol and hexane.

Figure 2: Effect of type of solvent used for washing immobilized preparation from CCL. (a) butanol, (b) diethyl ether, (c) methanol, (d) hexane. Reaction conditions: 1.33 mmol D-glucose, 1.33 mmol lauric acid, 5 ml ethyl methyl ketone, 30 mg CCL I at 60ºC, molecular sieves (4Aº) in equimolar quantity to the biocatalyst, 250 rpm.

| Solvent | Log P | Solubility (S) (mg/ml) |

|---|---|---|

| Butanol | 0.88 | 0.486 |

| Diethyl ether | 0.89 | 0.316 |

| Methanol | -0.77 | 0.255 |

| Hexane | 3.5 | 0.127 |

Table 1: Solubility of lauric acid in the washing solvents

These results are expected, considering that lauric acid is a hydrophobic molecule and therefore it is more miscible into butanol (log P=0.88, S=0.486) and diethyl ether (log P=0.89, S=0.316). Hexane showed the lowest value of fatty acid removal because it is a non-polar solvent (log P=3.50, S=0.127). It can be seen that the contact of CCL I with the solvents is only for 10 minutes and maintained the enzymatic activity of the lipase. Over 10 minutes, the polar solvents can dissolve the support by causing desorption of the enzyme [17]. If the contact between the lipase and the solvent is too long these polar solvents can strip water from the surface of the protein denaturing the structure of the lipase [18].

Effects of the washing solvents in the esterification activity

Reusability of the immobilized enzyme is relatively important for its industrial application [19]. To investigate the reusability, CCL I was washed with butanol, diethyl ether, methanol and hexane after one reaction cycle and reintroduced into a new esterification reaction. In order to obtain an evaluation of the effects of the washing solvents on the immobilized biocatalyst, CCL I was incubated in butanol, diethyl ether, methanol or hexane for 10 minutes under magnetic stirring, at 25°C. The results of relative esterification activities [20] obtained at 72 h after the contact of recovered CCL I with the solvents are shown in Table 2.

| Solvent | Log P | Used | Specific activity (μmols.min-1.g-1) |

|---|---|---|---|

| Butanol | 0.88 | 1 | 8.4 |

| 2 | 7.9 | ||

| Diethyl ether | 0.89 | 1 | 8.4 |

| 2 | 4.2 | ||

| Methanol | -0.77 | 1 | 8.4 |

| 2 | 3.3 | ||

| Hexane | 3.5 | 1 | 8.4 |

| 2 | 2.8 |

Table 2: Effects of the washing solvents in the esterification activity

Under the experimental conditions used in this work, it can be observed that after the first reuse the lipase retains 94% of its initial activity when washed with Butanol. This is probably due to the high solubility of lauric acid in this solvent (Table 1). 50% and 40% of specific activity were respectively obtained when the lipase is washed with diethyl ether and methanol. Hexane (log P=3.5) is a hydrophobic solvent and was chosen due to previous results obtained in the literature using this solvent for lipase washing [21]. 33% of initial activity of CCL I is maintained with this solvent. This may be due to the compromise between the polarity of used solvent and the washing time. Solubility of lauric acid in these solvents also contributes to obtained results for methanol, diethyl ether and hexane. After using the biocatalyst three times, the conversion decreased. The main reason for the loss of activity was due to the denaturation of the enzyme and to the leakage of protein from the support.

Conclusion

Immobilization provides an attractive possibility for consecutive use of the same biocatalyst. Lipase from C. cylindracea was successfully immobilized on celite and used for glucose ester synthesis. The activity and stability of immobilized lipase was highly dependent on the used washing solvent which determines polarity. The activity of lipase usually increased with decreasing polarity and the highest enzyme activity was achieved in butanol (94%). The stability of CCL I in medium polar solvent was observed. Beyond this property, it has environmental compatibilities, being considered a green chemistry for a long biocatalyst life.

Acknowledgement

The authors would like to acknowledge the Algerian Ministry of Scientific Research and the UBMA University for providing financial assistance to conduct this project in LOMOP Laboratory.

References

- M. Bello, D. Thomas, M. D. Legoy, Biochem. Biophys. Res. Commun., 1987, 146(1), 361.

- A.R.M. Yahya, W.A. Anderson, M. Moo-Young, Enzyme Microb. Technol., 1998, 23, 438.

- P.Y. Stergiou, A. Foukis, M. Filippou, M. Koukouritaki, M. Parapouli, Indian J. Exp. Biol., 2014, 52(11), 1045.

- A. Ursoiu, C. Paul, T. Kurtán, F. Péter, Molecules., 2012, 17, 13045.

- J.A. Silva, G.P. Macedo, D.S. Rodrigues, R.L.C. Giordano, L.R.B. Goncalves, Biochem. Eng. J., 2012, 60, 16.

- W. Kaewthong, S. Sarote, P. Poonsuk, H. Aran, Process Biochem., 2005, 40, 1525.

- S.K. Khare S.K, M. Nakajima, Food Chem., 2000, 68, 153.

- N. Rezgui, M. Aggouf, A. Aissaoui, C. Bidjou-Haiour, Biointerface Research in Applied Chemistry., 2016, 6(3), 1299.

- E. Hatziloukas, A. Afendra, A. Pandey, E.M. Papamichael, Biotechnol. Adv., 2013, 31(8), 1846.

- I.S. Yoo, S.J. Park, H.H. Yoon, J. Ind. Eng. Chem., 2007, 13, 1.

- S. Piccicuto, C. Blecker, J.C. Brohée, A. Mbampara, G. Lognay, Biotechnol. Agronom. Soc. Environ., 2001, 5, 209.

- M. Leitgeb, Z. Knez, J. Am. Oil Chemists' Society., 1990, 67, 775.

- S.K. Khare, M. Nakajima, Food Chem., 2000, 68(2), 153.

- N. Bouzaouit, C. Bidjou-Haiour. Biological Forum–An Intern. J., 2016, 8(1), 420.

- E.M. Anderson, K.M. Larsson, O. Kirk, Biocatalysis and Biotransformation., 1989, 16(3), 181.

- M. Ferrer, J. Soliveri, F.J. Plou, N. López-Cortés, D. Reyes -Duarte, Enzyme and Microbial Tech., 2005, 36, 391.

- V. Pace, J.V. Sinisterra, A.R. Alcantara, Curr. Org. Chem., 2010, 14, 2384.

- A.M. Gumel, M.S.M. Annuar, T. Heidelberg, Y. Chisti, Process Biochemistry., 2011, 46, 2079.

- J.M. Palomo, G. Muñoz, G. Fernández-Lorente, C. Mateo, R. Fernández-Lafuente, J. Molec. Catal. B: Enzym., 2002, 19, 279.

- E.C.G. Aguieiras, C.O. Veloso, J.V. Bevilaqua, D.O. Rosas, M.A.P. da Silva, Enzyme Research., 2011, 1.

- R.C. Rodrigues, G. Volpato, K. Wada, M.A.Z. Ayub, J. Am. Oil Chemists' Society., 2008, 85, 925.