Research Article - Der Pharma Chemica ( 2022) Volume 14, Issue 4

Oxygenated Apatites: Effect of Calcium Salt Nature and Synthesis Parameters

Soumia Belouafa*, Hassan Chaair and Khalid DiguaSoumia Belouafa, Laboratory of Process and Environment Engineering, Faculty of Sciences and Technologies Mohammedia. University Hassan II of Casablanca, Morocco, Email: soumia.belouafa@univh2c.ma

Received: 23-Mar-2022, Manuscript No. dpc-22-58149; Editor assigned: 25-Mar-2022, Pre QC No. dpc-22-58149 (PQ); Reviewed: 11-Apr-2022, QC No. dpc-22-58149; Revised: 14-Apr-2022, Manuscript No. dpc-22-58149 (R); Published: 22-Apr-2022, DOI: 10.4172/0975-413X.14.4. 26-33

Abstract

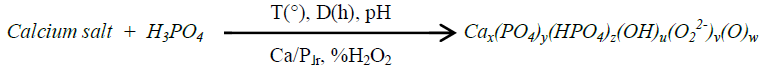

Apatitic calcium phosphates, reported in this study, are prepared following a precipitation reaction between phosphoric acid (H3PO4) and a calcium salt. Used salts are calcium carbonate (CaCO3), calcium nitrate (Ca(NO3)2) and calcium chloride (CaCl2). The variation in the chemical composition and crystallinity of oxygenated apatites, carbonated or not, depending on the nature of the reagents and the synthesis parameters was studied by X-ray diffraction, infrared spectroscopy and by chemical analysis. The insertion of molecular oxygen into the apatite tunnel is achieved through the use of hydrogen peroxide (H2O2). The content of molecular oxygen in the apatite is then determined by volumetric analysis.

Graphical abstract:

Keywords

Oxygenated apatite; calcium phosphate; precipitation; calcium salts; synthesis parameters; biomaterials

Introduction

Hydroxyapatite (HAP), Ca10 (PO4)6(OH)2, is the main constituent of human bone. By its excellent biocompatibility and its bone conductivity, this artificially synthesized compound is widely used as a bone graft substitute, a potential holder of drugs and for other applications [1-3].

Oxygenated apatites (Cax(PO4)y(HPO4)z(OH)u(O22-)v(O)w), belonging its family, has its properties of biocompatibility and osteoconductivity and also an antiseptic activity. Therefore, they are used as bone substitutes and as support matrices of antiseptic agents [4]. Following implantation, they undergo a process of degradation and dissolution joined with bone neo-formation and progressive release of oxygenated species (O2, O22-); liable for antiseptic activities [4]. For their synthesis, many methods have been developed [4-7]. We have developed, in a previous study [8], an oxygenated apatite based of calcium phosphate by precipitation reaction from calcium salt and orthophosphoric acid (H3PO4). The composition and crystal characteristics of apatite’s are, though, hard to control during the synthesis, mainly because of the ability of the lattice to accept substituents and vacancies [9, 10].

The present work aims to study in more detail the physico-chemistry of oxygenated apatites which could find future applications, for example in the treatment of bone and dental infections. In this paper, the preparation of apatites doped with oxygen species was examined, and the impact of calcium salt nature and synthesis conditions (temperature, ripening time, pH, atomic ratio of calcium to phosphorus (Ca/P ) and concentration of hydrogen peroxide) on their physico-chemical and morphological characteristics were studied by means of single factor test method.

Experimental

Preparation of oxygenated apatites

A solution of orthophosphate (H3PO4, 3.875 10-2 M), prepared in a mixture of H2O2/H2O, is added with stirring to a suspension or solution of calcium salt (CaCO3, Ca(NO3)2 or CaCl2), prepared in parallel in the similar H2O2/H2O medium, adjusted to the desired temperature and pH. The reaction medium is maintained, with stirring, at constant temperature and pH during the ripening time. After filtration, the precipitate is washed with distilled water and dried under vacuum at room temperature. The specific conditions for each of the experiments are reported in (Table 1). Thereby, Ap.OxCACO3, Ap.OxCa(NO3)2 and Ap.OxCaCl2 are prepared from CaCO3-H3PO4, Ca(NO3)2-H3PO4 and CaCl2-H3PO4, respectively.

T, D and pH correspond to the values of synthesis temperature, ripening time and pH of the reaction medium. Ca/ P r correspond to the atomic ratio of calcium to phosphorus. % H2O2 corresponds to the concentration of used H2O2.

Physico-chemical characterization

The nature and crystallographic structural features of the phases obtained in this work were investigated by X-ray diffraction (XRD) using a Seifert XRD 3000 P diff actomete (Cu Kα1Kα2 adiation). The counting time was of 60 s fo eve y step of 0.04°, typically in the 2θ ange 25-50°.

Complementary analyses were run by Fourier transform infrared spectroscopy (FTIR). Spectra were recorded on a Perkin-Elmer 1600 FTIR spectrometer in the range 400-4000 cm−1. The product (1 mg) being dispersed in a KBr matrix (300 mg) and compressed at 10 tonnes for 20 s to obtain a very fine pellet.

The chemical composition of the obtained samples was drawn from the measurement of ionic contents.

The determination of the calcium and orthophosphate (PO43− and HPO42−) ions contents were obtained, after acidic dissolution of the samples, by way of EDTA complexomet y and spect ophotomet y (using the phosphovanadomolybdenic complex, with λ = 460 nm) [11], espectively. The error in the calcium and the phosphorus contents is of the order of 0.5%.

Peroxide titration was performed by magnanimity titration using potassium permanganate KMnO4 [12]. The relative error on this dosage is approximately 1%.

The quantity of molecular oxygen contained in the apatites was established by measuring the gas volume released during the acid attack of apatite’s [13]. In the case of carbonate apatites, the same dosage is carried out using asbestos. The amount of carbonate ions is determined by the difference between the two volumes [13]. The relative uncertainty on the oxygen and carbonate contents is of the order of 2%.

Morphological characterization

The morphological study was performed using scanning electron microscopy (SEM) using Quanta 200 coupled with a computer enabling the image to be taken. The emission of electrons is done through a tungsten filament.

Results and Discussion

For this comparative physico-chemical study, we will present and examine the results of analyzes carried out by X-ray diffraction, infrared spectroscopy and by chemical analysis.

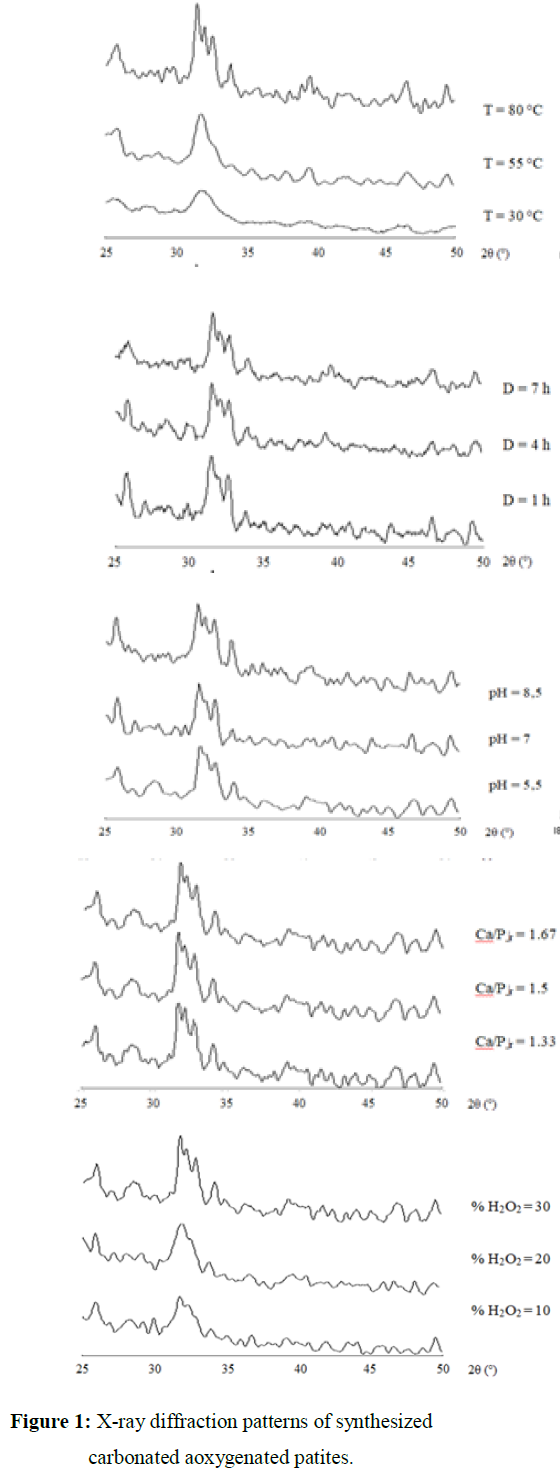

The oxygenated apatites (Ap.OxCaCO3, Ap.OxCa(NO3)2 and Ap.OxCaCl2) obtained from different experiments present X-ray diffraction patterns identical from crystallinity point of view, which prompted us to present only those of Ap.OxCaCO3 (Figure 1). These diffract grams do not detect the presence of any foreign phase in these apatites.

Due to the similarity of the evolution of infrared spectra of Ap.OxCaCO3, Ap.OxCa(NO3)2 and Ap.OxCaCl2 as a function of the synthesis parameters, we have only presented those of Ap.OxCaCO3 (Figure 2). All infrared spectra reveal the presence of the characteristic bands of the PO43- and HPO42- ions present in calcium-deficient apatites. Furthermore, the spectra of the carbonated oxygenated apatites also show bands characteristic of carbonate ions (CO32-).

The results of the chemical analysis of Ap.OxCACO3, Ap.OxCa(NO3)2 and Ap.OxCaCl2 prepared from various experiments are grouped together in (Table 2).

T, D and pH correspond to the values of synthesis temperature, ripening time and pH of the reaction medium. Ca/ P r correspond to the atomic ratio of calcium to phosphorus. % H2O2 corresponds to the concentration of used H2O2. Effect of reaction temperature

The influence of synthesis temperature on the composition of oxygenated apatites was studied on powders prepared at 30, 55 and 80 °C (Table 1; experiments 1-3).

The crystallinity of these apatites evolves according to the synthesis temperature. Indeed, it is observed that the higher the synthesis temperature, the peaks become more refined. This phenomenon is particularly visible on the four peaks located in the angular range 30°- 350

The infrared absorption spectra show that the intensity of the characteristic bands of the CO32- groups decreases when the synthesis temperature increased from 30ºC to 80ºC.

The results of chemical analysis show that the increase in temperature leads to an increase in the level of oxygenated species in the prepared apatites and to a reduction in the deviation from stoichiometry which results in an increase in Ca/P_r ratio of these apatites. In the case of Ap.OxCaCO3, the increase in temperature decreases the carbonate ion content of these apatites (Table 2), which is in agreement with the results of infrared spectra.

| Apatites | Parameters | Values | Ca/P | Chemical formulas |

|---|---|---|---|---|

| T (°C) | 30 55 80 |

1.586 1.620 1.650 |

Ca8.88(PO4)5.32(HPO4)0.28(CO3)0.40(OH)0.02(O22-)0.21(O2)0.1 Ca9.15(PO4)5.45(HPO4)0.20(CO3)0.35(OH)0.29(O22-)0.28(O2)0.2 Ca9.44(PO4)5.57(HPO4)0.15(CO3)0.28(OH)0.61(O22-)0.35(O2)0.3 |

|

| D (h) | 1 4 7 |

1.596 1.628 1.650 |

Ca9.10(PO4)5.44(HPO4)0.26(CO3)0.30(OH)0.02(O22-)0.37(O2)0.28 Ca9.30(PO4)5.51(HPO4)0.20(CO3)0.29(OH)0.37(O22-)0.36(O2)0.29 Ca9.44(PO4)5.57(HPO4)0.15(CO3)0.28(OH)0.61(O22-)0.35(O2)0.3 |

|

| Ap.OxCaCO3 | pH | 5.5 7 8.5 |

1.577 1.596 1.611 |

Ca9.05(PO4)5.38(HPO4)0.36(CO3)0.26(OH)0.04(O22-)0.34(O2)0.20 Ca9.10(PO4)5.44(HPO4)0.26(CO3)0.30(OH)0.02(O22-)0.37(O2)0.28 Ca9.14(PO4)5.49(HPO4)0.18(CO3)0.33(OH)0.01(O22-)0.39(O2)0.30 |

| Ca/Pûr | 1.33 1.5 1.67 |

1.571 1.596 1.637 |

Ca8.99(PO4)5.29(HPO4)0.43(CO3)0.28(OH)0.01(O22-)0.34(O2)0.16 Ca9.10(PO4)5.44(HPO4)0,.26(CO3)0.30(OH)0.02(O22-)0.37(O2)0.28 Ca9.30(PO4)5.62(HPO4)0.06(CO3)0.32(OH)0.20(O22-)0.39(O2)0.30 |

|

| % H2O2 | 10 20 30 |

1.551 1.570 1.596 |

Ca8.75(PO4)5.38(HPO4)0.26(CO3)0.36(OH)0.02(O22-)0.05(O2)0.01 Ca8.95(PO4)5.44(HPO4)0.26(CO3)0.30(OH)0.06(O22-)0.20(O2)0.10 Ca9.10(PO4)5.44(HPO4)0.26(CO3)0.30(OH)0.02(O22-)0.37(O2)0.28 |

|

| Ap.OxCa(NO3)2 | T (°C) | 30 55 80 |

1.588 1.625 1.655 |

Ca9.53(PO4)5.96(HPO4)0.04(OH)0.14(O22-)0.48(O2)0.41 Ca9.75(PO4)5.97(HPO4)0.03(OH)0.53(O22-)0.50(O2)0.43 Ca9.93(PO4)5.97(HPO4)0.03(OH)0.83(O22-)0.53(O2)0.53 |

| D (h) | 1 4 7 |

1.597 1.633 1.655 |

Ca9.58(PO4)5.95(HPO4)0.05(OH)0.07(O22-)0.57(O2)0.46 Ca9.80(PO4)5.96(HPO4)0.04(OH)0.54(O22-)0.55(O2)0.49 Ca9.93(PO4)5.97(HPO4)0.03(OH)0.83(O22-)0.53(O2)0.53 |

|

| pH | 5.5 7 8.5 |

1.578 1.597 1.610 |

Ca9.47(PO4)5.92(HPO4)0.08(OH)0.26(O22-)0.38(O2)0.44 Ca9.58(PO4)5.95(HPO4)0.05(OH)0.07(O22-)0.57(O2)0.46 Ca9.66(PO4)5.97(HPO4)0.03(OH)0.05(O22-)0.65(O2)0.51 |

|

| Ca/Pûr | 1.33 1.5 1.67 |

1.578 1.597 1.643 |

Ca9.47(PO4)5.96(HPO4)0.04(OH)0.02(O22-)0.48(O2)0.35 Ca9.58(PO4)5.95(HPO4)0.05(OH)0.07(O22)0.57(O2)0.46 Ca9.86(PO4)5.99(HPO4)0.01(OH)0.45(O22-)0.64(O2)0.52 |

|

| % H2O2 | 10 20 30 |

1.570 1.578 1.597 |

Ca9.42(PO4)5.96(HPO4)0.04(OH)0,12(O22-)0.38(O2)0.32 Ca9.47(PO4)5.97(HPO4)0.03(OH)0,05(O22-)0.46(O2)0.35 Ca9.58(PO4)5.95(HPO4)0.05(OH)0,07(O22-)0.57(O2)0.46 |

|

| Ap.OxCaCl2 | T (°C) | 30 55 80 |

1.590 1.627 1.658 |

Ca9.54(PO4)5.96(HPO4)0.04(OH)0.12(O22-)0.50(O2)0.45 Ca9.76(PO4)5.97(HPO4)0.03(OH)0.49(O22-)0.53(O2)0.48 Ca9.95(PO4)5.98(HPO4)0.02(OH)0.82(O22-)0.55(O2)0.54 |

| D (h) | 1 4 7 |

1.600 1.640 1.658 |

Ca9.60(PO4)5.96(HPO4)0.04(OH)0.06(O22-)0.59(O2)0.46 Ca9.84(PO4)5.97(HPO4)0.03(OH)0.57(O22-)0.57(O2)0.50 Ca9.95(PO4)5.98(HPO4)0.02(OH)0.82(O22-)0.55(O2)0.54 |

|

| pH | 5.5 7 8.5 |

1.580 1.600 1.620 |

Ca9.48(PO4)5.94(HPO4)0.06(OH)0.22(O22-)0.40(O2)0.43 Ca9.60(PO4)5.96(HPO4)0.04(OH)0.06(O22-)0.59(O2)0.46 Ca9.72(PO4)5.99(HPO4)0.01(OH)0.11(O22-)0.67(O2)0.52 |

|

| Ca/Pûr | 1.33 1.5 1.67 |

1.582 1.600 1.650 |

Ca9.49(PO4)5.95(HPO4)0.05(OH)0.03(O22-)0.50(O2)0.40 Ca9.60(PO4)5.96(HPO4)0.04(OH)0.06(O22-)0.59(O2)0.46 Ca9.90(PO4)5.99(HPO4)0.01(OH)0.51(O22-)0.65(O2)0.53 |

|

| % H2O2 | 10 20 30 |

1.582 1.588 1.600 |

Ca9.49(PO4)5.98(HPO4)0.02(OH)0.20(O22-)0.40(O2)0.33 Ca9.53(PO4)5.99(HPO4)0.01(OH)0.11(O22-)0.48(O2)0.36 Ca9.60(PO4)5.96(HPO4)0.04(OH)0.06(O22-)0.59(O2)0.46 |

Effect of ripening time

The influence of ripening time on the composition of oxygenated apatites was studied on powders prepared for 1, 4 and 7 h (Table 1; experiments 3-5).

The analysis of X-ray diffraction diagrams and infrared absorption spectra of the obtained apatites leads to the same results obtained during the study of the influence of synthesis temperature, that is to say that the ipening time of synthesis imp oves the state of the apatite’s c ystallinity. Likewise, the intensity of carbonate ions bands of Ap.OxCaCO3 decreases when the ripening time of synthesis increased from 1 to 7 h.

The results of chemical analysis of synthesized apatites show that the increase in the synthesis ripening time leads to significant variations in chemical composition. With a short synthesis ripening time, the precipitates contain numerous peroxide groups, little molecular oxygen and their Ca/P ratio is far from the stoichiometry. By prolonging ripening time, the amount of peroxide groups decreases while that of molecular oxygen increases. Simultaneously, apatite approaches stoichiometry. In the case of Ap.OxCACO3, the increase in the synthesis ripening time is reflected, moreover, by the decrease in the content of carbonate ions in the apatitic lattice, which was verified by infrared absorption spectroscopy.

Effect of pH of the reaction medium

The influence of pH of the reaction medium on the composition of oxygenated apatites was studied on powders prepared with a pH of 5.5, 7 and 8.5 (Table 1; experiments 5-7).

X-ray diffractograms of the apatites prepared at different pH of the reaction medium show that the increase in pH of the reaction medium improves the state of crystallinity of the obtained apatites.

Infrared spectroscopy reveals an increase in the characteristic bands of CO32- ions with increasing pH. Chemical analysis shows that the rise of pH of the reaction medium leads to a decrease in the deviation from stoichiometry of the obtained apatites and to a significant increase in their content of oxygenated species. We also note, in the case of Ap.OxCaCO3, an increase in the CO32- ion content which is in conformity with the results of infrared spectra.

Effect of Ca/P atomic ratio

The influence of atomic atio of calcium to phospho us Ca P of the eagents on the composition of oxygenated apatites was studied on powders prepared with Ca/P ratios equal to 1.33, 1.5 and 1.67 (Table 1; experiments 7-9).

X-ray diffractograms show that the prepared apatites retain their crystallinity state with increasing Ca/P ratio. Infrared spectra show that the increase in the Ca/P_r ratio does not reveal any significant influence.

The results of chemical analysis show that an increase in the atomic ratio Ca/P_r causes an increase both in the Ca/P_r ratio of the obtained solids, in their content of oxygenated species and in the amount of carbonates in the case of Ap.OxCaCO3.

Effect of hydrogen peroxide concentration

The influence of hydrogen peroxide concentration on the composition of oxygenated apatites was studied on powders prepared using hydrogen peroxide 10%, 20% and 30% solutions (Table 1; experiments 9-11).

| Experiments | T(°) | D(h) | pH | Ca/P˩r | % H202 |

|---|---|---|---|---|---|

| 1 | 30 | 7 | 7 | 1.5 | 30 |

| 2 | 55 | 7 | 7 | 1.5 | 30 |

| 3 | 80 | 7 | 7 | 1.5 | 30 |

| 4 | 80 | 4 | 7 | 1.5 | 30 |

| 5 | 80 | 1 | 7 | 1.5 | 30 |

| 6 | 80 | 1 | 5.5 | 1.5 | 30 |

| 7 | 80 | 1 | 8.5 | 1.5 | 30 |

| 8 | 80 | 1 | 7 | 1.33 | 30 |

| 9 | 80 | 1 | 7 | 1.67 | 30 |

| 10 | 80 | 1 | 7 | 1.5 | 10 |

| 11 | 80 | 1 | 7 | 1.5 | 20 |

X-ray diffractograms give the same results as those previously revealed in studies of the influence of temperature, ripening time and pH, which means that the degree of crystallinity improves with the increase of % H2O2.

Infrared spectroscopy does not reveal any significant variation in the intensity of the characteristic bands of apatite’s. Chemical analysis shows that the content of oxygenated species undergoes a marked increase with the rise in the concentration of the hydrogen peroxide solution. In parallel, the Ca/P_r ratio of the precipitates increases, while in the case of Ap.OxCaCO3, a significant decrease in the CO32- ion content is manifested from 10% to 20% of H2O2. Beyond this value, this content remains constant.

Effect of calcium salts on the morphology

The morphology of the studied powders, prepared with the three calcium salts under the operating conditions of the first experiment, was investigated by scanning electron microscopy (SEM). The results obtained by SEM are presented in (Figure 3). These images suggest porous aggregates of particles prepared from CaCO3, very compact grains of particles prepared from CaCl2, intermediate aspect of particles prepared from Ca(NO3)2. It is concluded that a variety of morphological states of these biomaterials can be obtained depending on the nature of the calcium salt. This widens their applications in medical fields.

Discussion

The results obtained from the study of the influence of synthesis parameters of Ap.OxCACO3, Ap.OxCa(NO3)2 and Ap.OxCaCl2 make it possible to obtain a wide range of compounds ranging from amorphous oxygenated apatite’s to well-crystallized oxygenated apatite’s, and from lacunar oxygenated apatite’s to oxygenated apatite’s close to stoichiomet y.

The study of the influence of temperature on the synthesis of oxygenated apatite’s shows that the temperature improves their state of crystallinity, reduces their deviation from stoichiometry, increases their rate of oxygenated species and in the case of carbonate apatite’s, it decreases their rate of carbonate ions.

The study of the influence of ripening time of the oxygenated apatite’s shows that the increase of maturation time improves the crystallinity state of these apatite’s, decreases their deviation from the stoichiometry and favors the insertion of the oxygenated species in the structure, as it disadvantages that of carbonate ions in the case of carbonate apatite’s.

The study of the influence of reaction pH shows that the increase of pH improves the crystallinity state of these apatites, on the other hand, it does influence their chemical composition. In fact, the increase in the pH of synthesis medium produces an increase in the Ca/P_r ratio and in the content of oxygenated species of the precipitated apatites. In the case of carbonate apatites, it produces an increase in the content of carbonate ions.

The study of the influence of Ca/P_r ratio shows that the increase in Ca/P_r ratio promotes an increase in the Ca/P_r ratio, and in the quantity of oxygenated species and carbonates prepared solids.

The study of the influence of titre of hydrogen peroxide shows that the increase of %H2O2 improves the state of crystallinity of the prepared solids, favors the increase of their Ca/P_r ratio as well as the insertion of oxygenated species in the apatite structure while it disadvantages the insertion of carbonate ions in the case of Ap.OxCACO3 especially at high concentration.

In accordance with these observations, there is dependence between the Ca/P_r ratio, % O2 and % O22- of the synthesized apatites and the synthesis parameters (temperature, ripening time, pH, ratio Ca/P_r and % H2O2). We will discuss this dependence, first, for the Ca/P_r ratio, then for the content of oxygen species and finally for the amount of carbonate ions.

Regarding the Ca/P_r ratio, its increase was observed with increasing temperature, maturation time, pH, Ca/P_r ratio, or % H2O2. Indeed:

• The precipitates which form at the beginning are amorphous phosphates deficient in Ca2+ ions. Chow et al. [14] have, in fact, observed that an amorphous calcium phosphate with a Ca/P_r atomic ratio between 1.30 and 1.60 is formed, from the first stage of precipitation of apatites in solution. Boskeyet and Posner [15], additionally, observed that the formation of an apatitic phase is always preceded by the formation of an amorphous phase. Légeros et al. [16] prepared by precipitation, at 100 °C and in a pH range varying from 4 to 11, the Hydroxyapatite (Ca10(PO4)6(OH)2), while at 60 °C and for a pH of 5 to 6, they detected the formation of the Octocalcium Phosphate (Ca8H(PO4)65H2O). This phenomenon was clarified by Heughebaert [17] who showed that the transformation of amorphous phosphate into apatitic phosphate is all the more rapid the higher the temperature. • pH of reaction medium determines the concentration and the type of phosphate species acting during precipitation. In fact, phosphoric acid is a tri-acid whose acidity constants for the different acid-base pairs, at 25 °C, are as follows [18]:

• H3PO4/H2PO4-, pK1 = 2.1; H2PO4-/HPO42-, pK2 = 7.2; HPO42-/PO43-, pK3 = 12.1.

In the case of utilization of phosphoric acid H3PO4 in a basic medium, the phosphorus is essentially be in the form PO43- and HPO42-. So, at basic pH, the formed apatites are closer to stoichiometry.

• The higher the Ca/P_r ratio, the richer the reaction medium is in Ca2+ and PO43- ions, which promotes the germination of calcium phosphates once precipitated and their evolution into a solid with a high Ca/P_r ratio at the expense of free Ca2+ and PO43- ions in solution [19].

• The evolution of Ca/P_r ratio of the solids as a function of the % H2O2 is positively correlated with the evolution of the content of these solids in oxygenated species by following the law of electronegativity of the unit cell of apatite. With regard to the composition of oxygenated species, all the studied parameters appear to be influential:

• The decomposition of H2O2 is promoted by increasing either the temperature or pH of reaction medium, which facilitates the incorporation of oxygenated species into the apatitic lattice and explains the increase in the content of oxygenated species in each of these two cases.

• The increase in the ripening time results by the decomposition of the peroxide groups present in the apatitic structure to molecular oxygen and by the incorporation of new peroxide groups existing into solution [17]. This process develops during the first hours of the evolution of the precipitates which also correspond to the increase in the Ca/P_r ratio of the solid phases as we have effectively mentioned.

These two phenomena are probably linked to a restructuring of the lacunar lattice of precipitated apatites [8], but, whose mechanism cannot be defined.

• The increase in the oxygenated species content of the solids, caused by the increase in the Ca/P_r atomic ratio, is directly linked to the increase in the Ca/P_r ratio of the solids. In fact, these two phenomena seem to be related to the charge balance of the elementary cell which must be neutral.

• Precipitation in the presence of hydrogen peroxide, of high percentage, promotes the increase in the content of oxygen species in the apatitic structure. This is due to the super saturation of the reaction medium with oxygenated species.

Regarding the carbonate ions present in Ap.OxCaCO3, we noticed that the carbonation of these apatites is favored by increasing the pH or the Ca/P_r ratio while it becomes less important by increasing the temperature, the maturation time or the % H2O2. These phenomena can be explained by the fact that the first two conditions favor the reduction of HPO42- ions; rival elements of CO32- ions in the occupation of B-sites of the apatitic structure [20].

Concerning morphology, it appearance of the synthesized powders suggests the typical apatite appearance as shown in (Figure 3). These images suggest porous aggregates of particles prepared from CaCO3, very compact grains of particles prepared from CaCl2 and intermediate aspect of particles prepared from Ca(NO3)2. The porosity of the apatite prepared from the CaCO3 can be due to release of CO2 during the attack acid of CaCO3 by hydrogen peroxide. The variety of morphological states of these biomaterials broadened their field of biomedical application. As the porous apatites exhibit strong bonding to the bone; the pores provide a mechanical interlock leading to a firm fixation of the material [21]. Bone tissue grows well into the pores, increasing strength of the apatite implant. It is realized that dimension and morphology of pores are crucial factors for an excellent osteointegraton. As for dense apatite, they are used for the formation of ceramic blocks with different forms and for the recovery of implants [22].

Conclusions

This work highlights the variation in the chemical composition, the cristallinity and the morphology of oxygenated apatites, carbonated or not, depending on the studied synthesis parameters (T, D, pH, Ca/P_r and % H2O2) and/or on the nature of the calcium salts. In fact, the Ca/P_r atomic ratio and the amounts of oxygenated species of the apatites vary as a function of one or more of these parameters. Indeed, the increase in the Ca/P_r ratio of the solids and the insertion of the oxygenated species are favored by the increase in the temperature, the repining time, the pH, the Ca/P_r ratio or the % H2O2. On the other hand, the insertion of the carbonate ions present in the Ap.OxCaCO3 is favored by the increase of the pH or of the Ca/P_r ratio while it is disadvantaged by an increase in the temperature, maturation time or the % H2O2.

In general, the temperature, pH of reaction medium, Ca/P_r and the % H2O2 reflect the influence of reaction medium on the oxygenated apatite composition, while the repining time appears to be more specifically linked to the evolution of the precipitates themselves after their formation.

In addition, it is found that the calcium salt nature had also effect on the morphology of oxygenated apatite powders which widens their fields of application.

REFERENCES

- Haider A, Haider S, Han SS et al., Rsc Advances. 2017, 7(13): p.7442-7458.

- Pu'ad NM, Koshy P, Abdullah HZ et al., Heliyon. 2019, 5(5): p.e01588.

- Britel O, Hamad M, Chaair H et al., Phosphorus Sulfur Silicon Relat Elem. 2004, 179(9): p.1857-1865.

- C Rey. Study of the relationships between apatites and molecular compounds. Thesis, Institut National Polytechniques, Toulouse. 1984.

- Simpson DR. Am Mineral Journal of Earth and Planetary Materials. 1969, 54(3-4): p.560-562.

- Ginebra MP, Traykova T and Planell JA. J Control Release. 2006, 113(2): p.102-110.

- Trombe JC. Thesis, Institute National Polytechniques, Toulouse. 1972.

- Belouafa S, Chaair H, Digua K et al., Phosphorus, Sulfur, and Silicon. 2005, 180(12): p.2679-2687.

- Torrent‐Burgués J, Gómez‐Morales J, López‐Macipe A et al., Cryst Res Technol CR. 1999, 34(5‐6): p.757-762.

- Gómez‐Morales J, Torrent‐Burgues J, Boix T et al., Cryst Res Technol CR. 2001, 36(1): p.15-26.

- Charlot G. Mass et Cie, Editeurs. 1974.

- Charlot G. Analytical chemistry methods: Qualitative and mineral analysis, Masson, Paris. 1966.

- Ledard C, Benque E, Lacout JL et al., U.S. Patent 5,141,561. 1992.

- Eanes ED. Monogr Oral Sci. 2001, 18: p.130-147.

- Boskey AL and Posner AS. J Phys Chem. 1976, 80(1): p.40-45.

- LeGeros RZ, Kijkowska R and LeGeros JP. Scanning electron microscopy. 1984, (4): p.1771-1777.

- Heughebaert JC. Institut National Polytechniques, Toulouse. 1977.

- Lucas S. Thesis, Faculty of Sciences and Techniques, Limoge. 2003.

- Belouafa S, Faouzi FE, Sallek B et al., Phosphorus, Sulfur, and Silicon and the Related Elements. 2014, 189 (9): p.1346-1353.

- Vignoles M, Bonel G and Young RA. Calcified tissue international. 1987, 40(2): p.64-70.

- Daculsi G, Passuti N, Martin S et al., J Biomed Mater Res. 1990, 24(3): p.379-396.

- Daculsi G and Legeros JP. J Biomed Mater Res. 1996, 31(4): p.495-501.

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at , Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref