Review Article - Der Pharma Chemica ( 2024) Volume 16, Issue 4

Overview on Osmotic Drug Delivery System

Pravinkumar Darji*, Jayendrakumar Patel, Binit Patel and Shalin ParikhPravinkumar Darji, Department of Lifesciences, Shree SK Patel College of Pharmaceutical Education and Research, Gujarat, India, Email: palo378@gmail.com

Received: 02-Jan-2024, Manuscript No. DPC-24-124326; Editor assigned: 05-Jan-2024, Pre QC No. DPC-24-124326 (PQ); Reviewed: 12-Jan-2024, QC No. DPC-24-124326; Revised: 01-Aug-2024, Manuscript No. DPC-24-124326 (R); Published: 29-Aug-2024, DOI: 10.4172/0975-413X.16.4.425-432

Abstract

The aim of the current review is to elaborate on the osmotic drug delivery system for controlled release of drugs. The oral route is the most conventional and acceptable route of drug administration. Osmotic Drug Delivery Systems (ODDS) are gaining importance as these systems deliver the drug at specific times as per the functional needs of the disease, resulting in improved patient therapeutic efficacy and compliance. The osmotic drug delivery system serves as a tool for controlling drug release in these conditions and avoiding frequent administration, which is necessary for the treatment of chronic diseases that require repeated dose administration. To control drug delivery, they employ the osmotic pressure theory. To a significant extent, the drug's release is independent of GIT functional variables. This review paper highlights the osmotic drug delivery system's structure, numerous unique osmotic technologies, various factors that affect the drug's release from the system and the status of currently sold and in-progress products that use the system.

Keywords

Plasma concentration; Controlled drug delivery; Osmotic drug delivery; Osmosis; Osmotic pressure

Introduction

As the oral route provides the good active surface area of any drug delivery mechanism for administration of several drugs, oral drug delivery is the most admired and useful option. The entire scope of a drug's action is determined by its therapeutic function and how effectively it reaches the aid site. [1-5] The bioavailability of drugs from these formulations may differ significantly depending on factors such as the physicochemical properties of the drug, the presence of excipients and various physiological factors such as the presence or absence of food, GI motility and the pH of the GI tract. Controlled drug delivery systems' major goal is to increase the efficacy of drug therapies through prolonged or sustained drug release over a longer period. One essential field for drug research and development is Novel Drug Delivery Systems (NDDS). The NDDS's estimated launch time and cheap development costs ($20-50 million and 3-4 years, respectively) as compared to the new chemical molecule's ($500 million and 10-12 years, respectively) are the primary factors.

The most reliable Controlled Drug Delivery Systems (CDDS) are osmotic systems, which can also be used for oral drug delivery. These systems release the drug in a controlled manner by using osmotic pressure as their driving mechanism. Osmotic Pump Tablets (OPT) generally consist of a core including the drug(s), an osmotic agent, other excipients and a semipermeable membrane coat [6-8]. According to this system, osmotic drug administration produces superior outcomes than any other controlled release approach because it doesn't depend on the concentration of the drug. By preserving a largely constant, effective medication level in the body and minimizing negative side effects, controlled drug release systems try to maintain drug action at a predetermined rate [1-3].

Literature Review

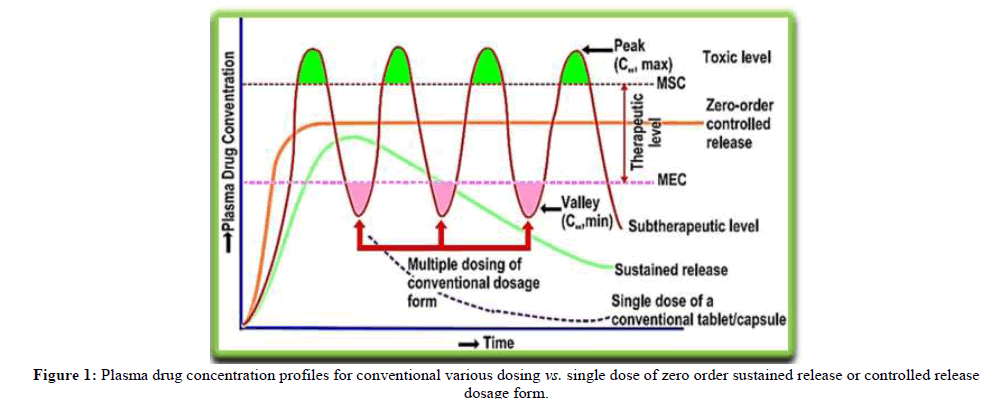

To maintain optimal plasma levels in such circumstances, a technique of continuous consumption of the therapeutic substance is necessary, as shown in Figures 1 and 2.

Classification of osmotic drug delivery system

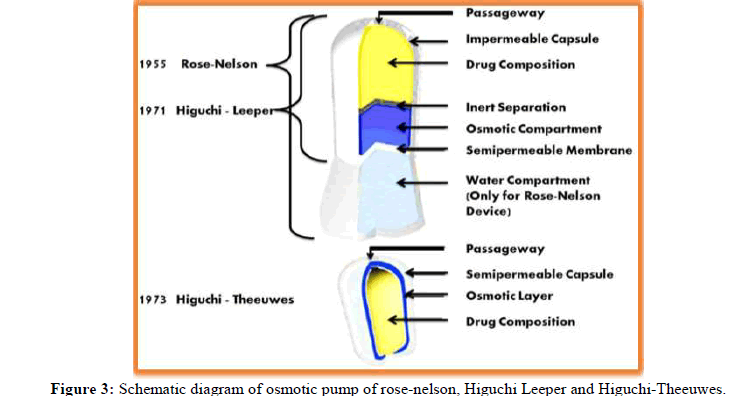

The Rose-Nelson pump: In 1955, two Australian physiologists, Rose and Nelson, reported the first osmotic pump. They were interested in the delivery of drugs to the guts of sheep and cattle.

• A drug chamber with an orifice.

• A salt chamber with an elastic diaphragm containing excess solid salt.

• A water chamber.

The drug and water chambers are separated by a rigid, semipermeable membrane. The difference in osmotic pressure across the membrane moves water from the water chamber into the salt chamber [4]. The volume of the salt chamber increases because of this water flow, which distends the latex diaphragm, separating the salt and drug chambers and pumping drugs out of this device. The pumping rate of the Rose-Nelson pump is given by the equation:

dm/dt=dv/dt*c

Where,

dm/dt=Drug release rate.

dv/dt=Volume flow of water into salt chamber.

c=Concentration of drug into drug chamber.

Higuchi Leeper pump: The design of the Higuchi Leeper pump described in the article represents the first simplified version of the Rose Nelson pump made by the Alza corporation in the early 1970’s. The benefit of this pump over the Rose Nelson pump is that it does not have a water chamber and the device is activated by water absorbed from the surrounding environment [5]. This means the pump is first prepared, then loaded with the drug and then stored for weeks or months prior to use.

Higuchi-Theeuwes pump: In the early 1970 Higuchi-theeuwes developed a similar form of rose nelson pump. The semipermeable wall itself acts as a rigid outer casing of the pump. The device is loaded with drug prior to use. When the device is put in an aqueous environment the release of the drug follows a time course set by the salt used in the salt chamber and the permeability of the outer membrane casing (Figure 3).

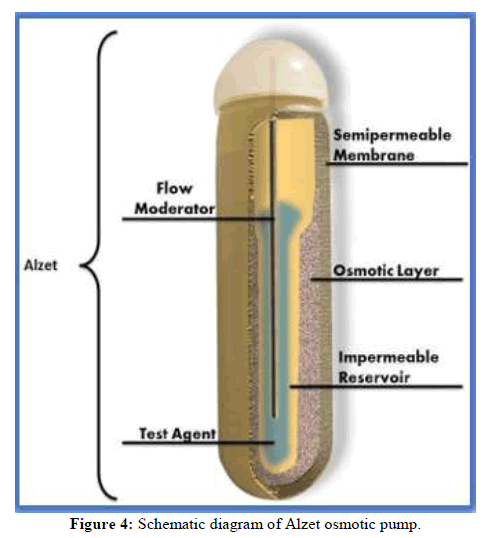

Alzet osmotic pump: Alzet pumps operate due to the difference in osmotic pressure between the inner chamber of the pump, called the salt sleeves and the area of tissue where the pump is implanted. The water fluxes into the tap through the SPM due to the high osmolality of the salt sleeve that forms the outer side of the pump. When water enters the salt sleeve, it compresses the flexible reservoir, removing the test solution from the pump at a controlled, predetermined rate [6]. The limitation of pumps is that they are designed for single use only because compressed reservoirs cannot be refilled (Figure 4).

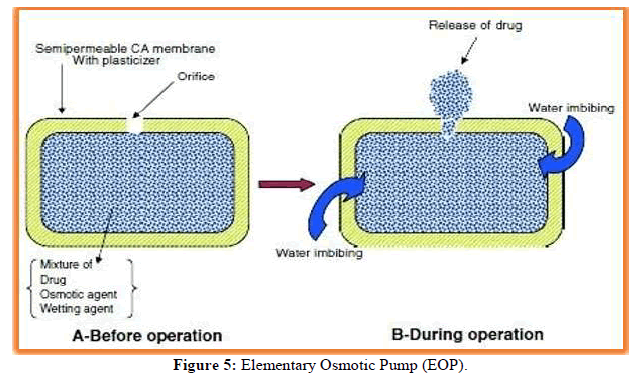

Elementary osmotic pump

An osmotic core (containing a drug with or without an osmogent) is coated with a Semipermeable Membrane (SPM) and a small orifice is created in the membrane. Imbibes water through the SPM because of the osmotic pressure gradient and forms a saturated solution inside the device. This increases the hydrostatic pressure inside the tablet and forces the saturated drug solution through the orifice present in the membrane. Advantage: Suitable for delivery of drugs having moderate water solubility (Figure 5).

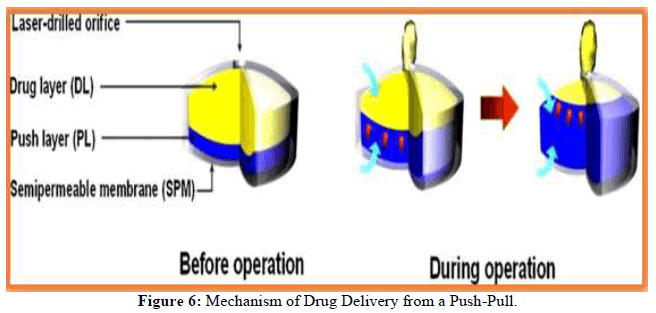

Push pull osmotic pump

Two compartments: The upper compartment (the drug compartment) contains the drug along with osmotically active agents. The lower compartment (push compartment) contains the polymeric osmotic agents. When the dosage form meets the aqueous environment, both compartments imbibe water simultaneously. Because the lower compartment is devoid of any orifice, it expands and pushes the diaphragm into the upper drug chamber, thereby delivering the drug via the delivery orifice.

Advantage: Deliver both highly water-soluble (oxybutynin hydrochloride) and practically water-insoluble (nifedipine, glipizide) drugs (Figure 6).

Discussion

Osmotic pump with non-expanding second chamber

Multi-chamber devices consist of systems containing a nonexpanding second chamber. The purpose of the second chamber is either dilution of the drug solution leaving the device (particularly useful in handling drugs with a high incidence of GI irritation) or simultaneous delivery of two drugs. Advantage: Relatively insoluble drugs can also be delivered [7].

Controlled Porosity Osmotic Pump (CPOP)

CPOPs are similar to EOPs, with the only difference being that the delivery orifice from which the drug release takes place is formed by the incorporation of a water-soluble additive in the coating. After coming into contact with water, the water-soluble additives present in the coating dissolve, resulting in the in situ formation of a microporous membrane as shown in Figure 7. The release of drugs takes place through this microporous channel [8]. Eliminates the need for a separate manufacturing step (creating an orifice using a laser drilling machine). Suitable for delivery of drugs having intermediate and extreme water solubility.

Osmotically rupturable pumps

Another popular category is osmotic systems that release the active ingredient through an osmotic bursting device. The system was developed by baker and consists of an osmotic core surrounded by an SPM. Water is osmotically attracted to this device when it is in a liquid environment, which results in the placement of the membrane within the device. This process continues until the internal pressure inside the device becomes greater than the cohesive force of the membrane and the membrane breaks down in a weak area, usually around the edges. When the membrane is raptured, the device becomes like an elementary osmotic pump and the drug compound is pulled out of the cracked area with the mechanism of osmotic pumping [9].

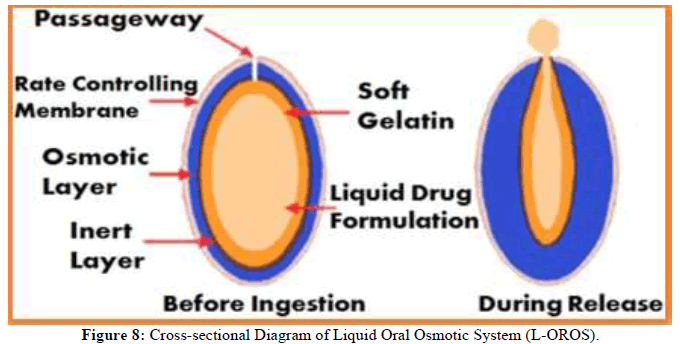

Liquid Oral Osmotic System (L-OROS)

The various LOROS systems available to provide controlled delivery of liquid formulations include a L-OROS soft cap, a L-OROS hard cap and a delayed liquid bolus delivery system. Each of these systems includes a layer of liquid drugs, an osmotic engine or a Push layer and a SPM. When this system meets water, the water penetrates inside the layer through SPM and activates an osmotic layer [10]. The expansion of the osmotic layer leads to the formation of hydrostatic pressure within the system, thereby forcing the liquid formulation to extrude from the orifice at the delivery site. While L-OROS hard caps and L-OROS soft caps are designed to provide continuous drug delivery, the L-OROS delayed delivery of liquid bolus system is designed to deliver a pulse of liquid drug (Figure 8).

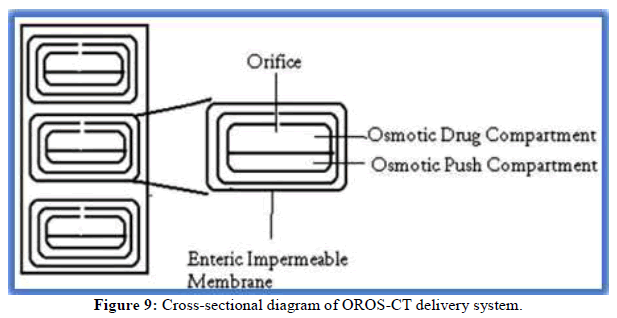

Colon Targeted Oral Osmotic System (OROS-CT)

OROS-CT is used to deliver drugs once or twice a day to the colon region. It comprises a hard gelatin capsule filled with 5-6 enteric-coated pushpull osmotic units for targeted drug delivery to the colon region. After contact with GI fluid, the gelatin capsule dissolves, but the enteric coating will prevent the entry of fluid from the stomach into the system (Figure 9).

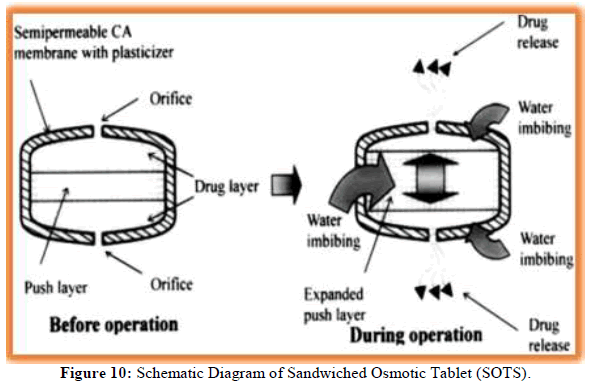

Sandwiched Osmotic Tablets (SOTS)

It consists of a polymeric push layer sandwiched between two layers of the drug with two delivery orifices. When placed in a liquid environment (Figure 10), the central push layer containing the swellable polymer starts to swell and the drug starts to release from the delivery orifice. The advantage of this type of system is that the drug is extruded from two opposite side layers of the tablet and therefore SOTS may be suitable for drugs that tend to cause local irritation of the abdominal cord (gastric mucosa) [11].

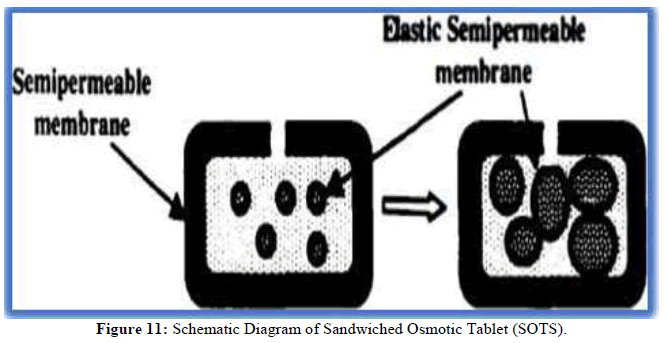

Osmotic pump for insoluble drugs

It consists of coating the particles of the osmotic agent (osmogens) with a SPM. These particles are mixed with an insoluble drug substance and pressed into the form of a tablet, after which they are encased in a SPM and an orifice is formed on the membrane (Figure 11).

After its contact with the liquid, the water is drawn through both layers to the particles of the osmotic agent, which then swells and pushes the drug hydrostatically through a delivery orifice.

Monolithic osmotic systems

It comprises a simple dispersion of a water-soluble substance in a polymeric matrix. When the system meets a liquid environment, the water uptake by the drug substance ruptures the polymer matrix, thereby releasing the drug into the external environment. Initially, this process takes place on the outer surface of the polymer matrix but gradually progresses to the inner surface in a consistent manner. However, this system fails if more than 20 to 30% of the active agent is incorporated into the osmotic system.

Telescopic capsule for delayed release

The device has two chambers: the first contains the delivery orifice and drug and the second contains the osmotic engine. A wax-like layer separates the two chambers. To assemble the delivery device, the drug substance is placed in one of the chambers with a manual or automatic filling mechanism. A two-layer tablet with an osmotic engine is placed on the part of the capsule cap with a convex osmotic layer shown at the end of the cap and a barrier at the end of the closed cap and a barrier layer is exposed at the opening of the cap. The filled vessel open end is fitted to the inner side of the cap open end, followed by compressing the two pieces together till the osmotic bilayer tablet, cap and vessel fit tightly together. When fluid enters the housing of the dispensing device, it will expand the osmotic engine, exerting pressure on the slidingly connected sections of the second and first walls. Which leads to the flow of surrounding fluid driven by the pressure that enters the reservoir, is minimal and consequently no agent will deliver during that period [12-14].

Multiparticulate delayed-release system

In this system, pellets comprising water-soluble drugs, optionally with osmotic agents, are coated with a SPM. When it comes into contact with water, water enters the core and forms a saturated solution of drug substances. The osmotic pressure gradient causes fluid influx, leading to rapid fluid enlargement that causes membrane expansion and the formation of pores. The release of drug ingredients through these holes usually follows zero-order kinetics. In studies conducted by Schultz and Kleinebudde, it was found that lag times and release rates depend on the level of thickness of the coating layer and the osmotic pressure of the dissolution medium.

Osmotic Matrix Tablet (OSMAT)

It is an osmotically operated matrix system that uses hydrophilic polymer material to swell and gel into a liquid that makes it semi-permeable in situ. Release from such a matrix system containing osmogent; therefore, it can be modulated by phenomena of the osmosion. OSMAT thus follows both matrix and osmotic aspects, leading to quantum improvements in drug delivery from swellable matrix systems. Osmotic matrix tablets are very easy to produce and do not require SPM coating or an orifice for drug delivery. Therefore, it is a less expensive technology and can be utilized for a variety of drugs (Table 1) [15].

| Osmotic pressures of saturated solution of commonly used osmogens | Osmotic pressure (atm) |

|---|---|

| Sodium chloride | 356 |

| Fructose 3 | 55 |

| Potassium chloride | 245 |

| Sucrose | 150 |

| Xylitol | 104 |

| Sorbitol | 84 |

| Dextrose | 82 |

| Citric acid | 69 |

| Tartaric acid | 67 |

| Mannitol | 38 |

| Potassium sulphate | 39 |

| Lactose | 23 |

| Fumaric acid | 10 |

Table 1: A list of various osmogens with their osmotic pressure.

The Semipermeable membrane

An important part of the osmotic drug delivery system is the semipermeable membrane housing. Therefore, the polymeric membrane selection is important to the osmotic delivery formulation. The membrane should possess certain characteristics, such as

• Sufficient wet strength and water permeability • Should be biocompatible • Rigid and non-swelling • Should be sufficiently thick to withstand the pressure within the device

Conclusion

Drug delivery systems have advanced in recent years. In this era of modern science and technology, novel drug delivery systems have been an attractive and recognized drug delivery system for the pharmaceutical and health industries. The major advantages include precise control of zeroorder release over an extended time period and consistent release rates can be achieved irrespective of the environmental factors at the delivery site. Modifications implemented over time and many more possibilities for these systems indicate more promising drug delivery for nearly a decade. Osmotic drug delivery systems usually contain a drug compound containing Osmogent in the core, coated with a semipermeable membrane. This coating has one or more delivery holes through which the solution or suspension of the drug is released over time. In osmotic delivery systems, osmotic pressure depletes the ability to release drugs through the delivery hole in the dosage form. In the future, various efforts are being made to produce a successful osmotic system, such as pulsatile delivery in terms of an expandable orifice, a lipid osmotic pump, a telescopic capsule containing a small osmotic pump for delayed discharge, an osmotic bursting osmotic pump and so on.

Modified versions of conventional dosage forms have been introduced to overcome the limitations of traditional dosage forms. The revised versions are known as controlled-release drug delivery systems. Among the various controlled-release systems, osmotic pumps are widely accepted and employed to control drug delivery. As is discussed in this review, osmotic pressure is the principle of this system. The drug release pattern, which is independent of pH and physiological factors, is one of the significant benefits of this system, making predetermined drug release rates possible.

References

- Patel J, Parikh S, Patel S. World J Pharm Res. 2021; p. 10:29.

- Verma RK, Mishra BA, Garg S. Drug Dev Ind Pharm. 2000; 26(7): p. 695-708.

[Crossref] [Google Scholar] [PubMed]

- Verma RK, Krishna DM, Garg S. J Control Release. 2002; 79(1-3): p. 7-27.

[Crossref] [Google Scholar] [PubMed]

- Rao AA, Rao VN, Devi AS, et al. Int J Pharma Chem Res. 2015; 1(1): p. 6-15.

- Verma RK, Garg S. Pharm Technol. 2001; 25(2): p. 1-4.

- Jerzewski R, Chien Y. Treatise on controlled drug delivery: Fundamentals, optimization, application. Marcel Dekker, Inc. New York, 1992; 225-253

- Santus G, Baker RW. J Control Release. 1995; 35(1): p. 1-21.

- Padma VD, Patil GP, Dabholkar RD. Osmotic DDS-An overview. Express Pharma Pulse, special feature. 2003; 29: p. 36-38.

- Wong PS, Barclay BL, Deters JC. Osmotic device for administering certain drugs. United States patent US 4,765,989. 1988.

- Theeuwes F. J Pharm Sci. 1975; 64(12): p. 1987-1991.

[Crossref] [Google Scholar] [PubMed]

- Higuchi T, inventor; Alza Corp, assignee. Osmotic dispenser with collapsible supply container. United States patent US 3,760,805. 1973.

- Higuchi T, Leeper HM. Osmotic dispenser with means for dispensing active agent responsive to osmotic gradient. United States patent US 3,995,631. 1976.

- Appel LE, Zentner GM. Pharmaceu Res. 1991; 8: p. 600-604.

- Zentner GM, Rork GS, Himmelstein KJ, et al. Controlled porosity osmotic pump. United States patent US 4,968,507. 1990.

- Baker RW. Controlled release delivery system by an osmotic bursting mechanism. United States patent US 3,952,741. 1976.