Research Article - Der Pharma Chemica ( 2021) Volume 13, Issue 11

Formulation and evaluation of Embelin (a phytoconstituent) loaded Phytosome complex

DK Vishwakarma, KM Priti, Sanjay Krishna Pandey* and JN MishraSanjay Krishna Pandey, Department of Biotechnology, Meerut Institute of Engineering and Technology, Meerut 250005, India, Email: dhaneshwarvish@gmail.com

Abstract

Embelin was one of active constituents of Embelia ribes Burm. f. Embelin has been reported to possess many pharmacological effects. The studies was perform to enhance the bioavailability of poorly water soluble embelin, reduce the dose of Embelin, prevent the degradation of Embelin in the GIT. For this, phytosome, a novel drug delivery system, was adopted. Total six Embelin loaded phytosome complex formulations coded as EMBP1, EMBP2, EMBP3, EMBP4, EMBP5 and EMBP6 using soya lecithin and Chitosan in variable ratio were prepared by anti-solvent precipitation method and Rotary evaporation technique. The phytosome was characterized by parameters like percentage yield, particle size determination, entrapment efficiency, scanning electron microscopy (SEM), in vitro release studies and establish drug release kinetic studies. Among six formulations, the Formulation EMBP5 well optimized. EMBP5 exhibits lowest 345.45 ±1.231 diameter. The entrapment efficiency of Embelin loaded phytosome complex varies from 64.99 ± 1.546 to 81.78 ± 1.151%. Embelin loaded phytosome complex formulation (EMBP5) exhibits highest of 81.78 ± 1.151% entrapment efficiency. SEM photomicrographs of optimized formulation (EMBP5) of Embelin loaded phytosome complex showed that the phytosomes are less spherical with smooth and rough surface and slightly aggregated. In vitro dissolution study of phytosome sshowed extended release pattern. From the data, the release of embelin from Embelin loaded phytosome complex was by fickian diffusion mechanism and followed first order kinetics (concentration dependant).

Keywords

Phytosome, Embelin loaded phytosome complex, Soya lecithin, Chitosan, entrapment efficiency, SEM.

Introduction

According to WHO, more than 80% people of the world shows their reliability towards herbal medicines. Active constituents extracted from plants have been used to treat various diseases since ancient times. Novel drug delivery system is a novel approach to drug delivery that addresses the limitations of the traditional drug delivery systems. However, the drug delivery system used for administering the herbal medicine to the patient is traditional and out-of-date, resulting in reduced efficacy of the drug. If the novel drug delivery technology is applied in herbal medicine, it may help in increasing the efficacy and reducing the side effects of various herbal compounds and herbs. This is the basic idea behind incorporating novel method of drug delivery in herbal medicines [1].

The bioavailability of active principles of plant has become a problem of concern for researchers attributable to poor oral bioavailability of the many of plants, specifically those containing polyphenolic rings in their structures like flavonoids, terpenoids and tannins.

A variety of solutions have been proposed to counter the problem of poor absorption, such as the preparation of emulsions, liposomes, and nanoparticles as well as the modification of chemical structures and delivery as prodrugs [2]. Among the potential strategies, phyto-phospholipid complexes (known as phytosomes) have emerged as a promising strategy to enhance the bioavailability of active constituents.

Indena, an Italian pharmaceutical and nutraceutical company, first developed the complexation of plant extracts containing water-soluble constituents with phospholipids to improve their bioavailability [3]. They patented the technology as ‘PHYTOSOME®’. The term “phyto” means plant and “some” means cell like.

Phytosomes loaded drug delivery system are prepared from the reaction of the phospholipids like phosphatidylcholine and polymer with the standardized plant extract or polyphenolic phytoconstituents or flavonoids of herbal extracts like gingko, grape seed, hawthorn, milk thistle, green tea and ginseng in aprotic solvent.

Embelin (2,5-3-undecyl-1,4-benzoquinone; Figure 1) is one of the constituents found in plants of the Myrsinaceae family, especially in Embelia and Ardisia sp8. Embelin was one of active constituents of Embelia ribes Burm. f. Embelin has been reported to possess many pharmacological effects including antifertility, analgesic, anti-inflammatory, antioxidant, antidiabetic, hepatoprotective, anticonvulsant, anxiolytic and antimicrobial activity [4].

The strategy of complexation of plant drugs or extracts with phospholipids or excipients is one of the best strategies for enhancing bioavailability and helpful viability of various inadequately absorbed plant constituents. Keeping this point of view, the study was performed. Embelin is insoluble in water and soluble in organic solvent, lower oral bioavailability and degradation of embelin in stomach. The studies was perform to Increase the bioavailability Embelin, reduce the dose of Embelin, prevent the degradation of Embelin in the GIT and explore the possibilities of administering Embelin in novel drug delivery system i.e. as phytosome [5].

Materials and Methods

Procurement and identification of Embelin

A gift sample of Embelin was procured from Akums Drugs & Pharmaceuticals Ltd., Haridwar, (India). The pure sample of Embelin was off-white to light yellowish-white powder.

Drug-excipient physical compatibility study

The pure Embelin was studied for compatibility testing with the phospholipid and polymer used for preparation of phytosome. Pure Embelin, soya lecithin and chitosan were mixed together as 1:1:1 ratio. The compatibility of Embelin with phospholipid and polymer was analyzed by Fourier Transform Infra-Red Spectroscopy method. An IR spectrum of Embelin with phospholipid and polymer was recorded by FTIR spectroscopy (Shimadzu-8404 S, Japan). The physical compatibility studies of Embelin and its physical mixture with soya lecithin and chitosan was further done by DSC (Differential Scanning Calorimetry, Shimadzu DSC-55, Japan) study.

Preparation of Embelin loaded phytosome complex

“Anti-solvent precipitation method” and “Rotary evaporation technique” were used for the preparation of phytosome loaded complex formulations of Embelin. Six formulations of Embelin loaded phytosome were prepared (Table 1).

| Phytosomes | Drug : Phospholipid (Molar ratio) | Polymer (Chitosan) (%w/v) | Solvent (Ethanol) ml | Solvent (n- Hexane) ml | |

|---|---|---|---|---|---|

| Drug (Embelin) | Phospholipid (Soya lecithin) | ||||

| EMBP1 | 1 | 1 | 0.25 | 50 | 30 |

| EMBP2 | 1 | 1.5 | 0.25 | 50 | 30 |

| EMBP3 | 1 | 2 | 0.25 | 50 | 30 |

| EMBP4 | 1 | 1 | 0.5 | 50 | 30 |

| EMBP5 | 1 | 1.5 | 0.5 | 50 | 30 |

| EMBP6 | 1 | 2 | 0.5 | 50 | 30 |

Anti-solvent precipitation method

Anti-solvent precipitation method was used to prepare three formulations of Embelin loaded phytosome coded as EMBP1, EMBP2 and EMBP3.

Required molar ratio of Embelin and Soya lecithin were taken in 100ml of round bottomed flask (RBF) containing 50 ml of ethanol. Mixture of RBF was ultra sonicated for 30 min for uniform solution. The solution was now refluxed about 3 h in a magnetic stirrer at temperature not exceeding 550C. This solution was concentrated upto 10 ml. To this solution, 30 ml n-hexane was added and mixed preciously to get precipitate. This precipitate was introduced drop to drop into a solution of 2% aqueous acetic acid (v/v) solution of chitosan (0.25 % w/v) with continuously stirred using a magnetic stirrer with increasing the temperature upto 550C. The precipitated Embelin loaded phytosome complex was placed in desiccator for overnight. Powdered Embelin loaded phytosome complex was stored in amber coloured bottle at room temperature.

Rotary evaporation technique

Rotary evaporation technique was used to prepare three formulations of Embelin loaded phytosome coded as EMBP4, EMBP5 and EMBP6. Embelin and Soya lecithin (both in required molar ratio) were taken in round bottomed flask (RBF) of rotavapour. 50 ml of ethanol was added to the flask. The flask was fitted to rotavapour and refluxed about 3 h at temperature not exceeding 400C. A thin film of complex in ethanol solvent was obtained. This thin film was introduced drop to drop into a solution of 2% aqueous acetic acid (v/v) solution of chitosan (0.25 % w/v) with continuously stirred using a magnetic stirrer with increasing the temperature. The precipitated Embelin loaded phytosome complex was placed in desiccator for overnight. Powdered Embelin loaded phytosome complex was stored in amber coloured bottle at room temperature.

Preparation of standard calibration curve of pure Embelin

Stock solution: The standard stock solution was prepared by dissolving 10 mg of pure Embelin in volumetric flask and volume was adjusted to the mark with methanol to form a concentration of 100 μg/ml of drug in solution.

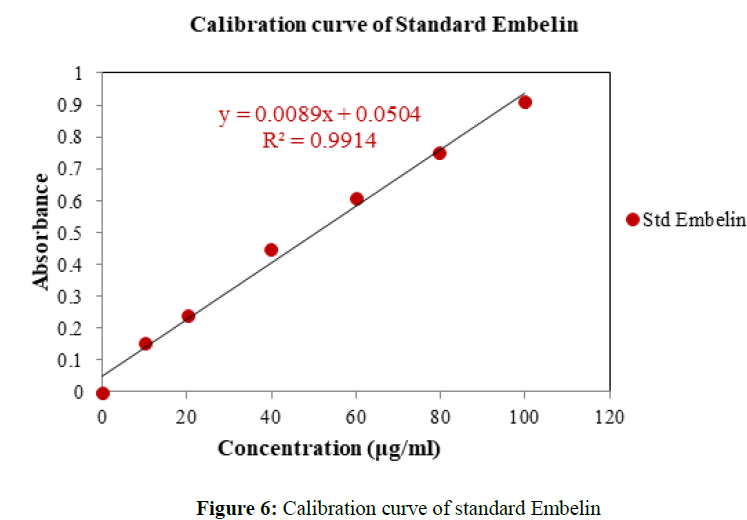

Calibration curve of pure Embelin: A series of dilutions were prepared from the standard stock solutions ranging from 10 μg/ml, 20 μg/ml, 40, μg/ml, 60 μg/ml, 80 μg/ml and 100 μg/ml of Embelin. Absorbance was recorded at 289 nm under UV spectrophotometer. All the measurements were taken three times to ensure accuracy of the results. The absorption spectrum of the solution was recorded ranging from 200 to 800 nm using methanol as a blank. The absorbance of these solutions was measured and a graph of concentration versus absorbance was plotted.

Evaluation of Embelin loaded phytosome complex.

Percentage yield of Embelin loaded phytosome complex: Each formulation of Embelin loaded phytosome complex was properly dried and weighed. The percentage yield of floating microspheres of each formulation was calculated using following formula:

Percentage yield=(Practical yield)/(Theoretical yield)

Where, Practical yield = Weight of prepared phytosome; Theoretical yield = Initial weight of the Embelin, phospholipid and polymer

Particle (Embelin loaded phytosome complex) size determination

The particle size of the Embelin loaded phytosome complex formulations was measured by the dynamic light scattering (DLS) technique using particle size analyser. The formulated Embelin loaded phytosome complex was dispersed in deionized water and this was used for determination of particle size. The analysis was performed thrice and all the measurements were carried out at a temperature of 25°C.

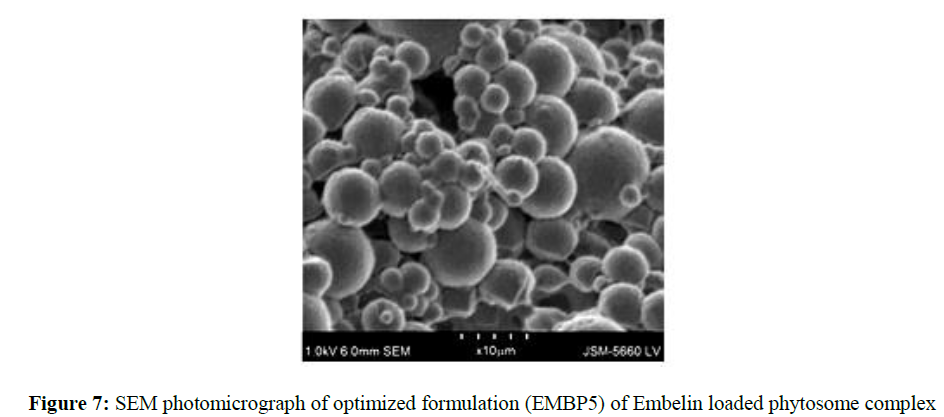

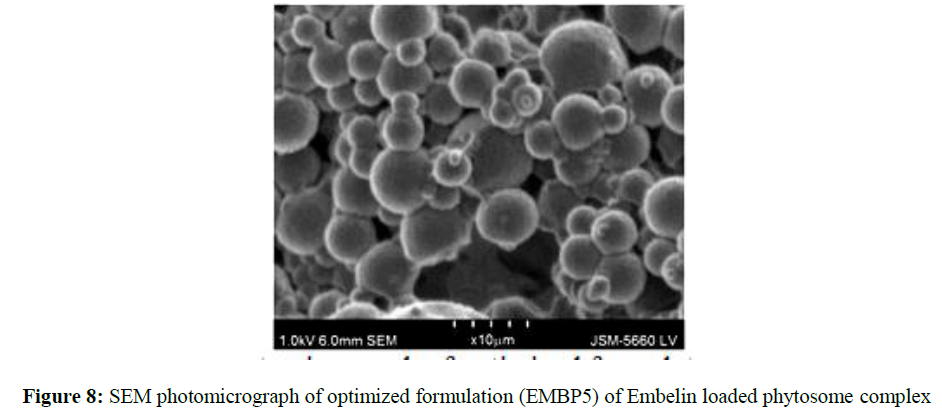

Study of surface morphology

Scanning Electron Microscopy (SEM) of the optimized formulation (i.e. EMBP5) of Embelin loaded phytosome complex was performed by Scanning Electron Microscope (Model JSM-5660 LV). Microphotograph taken from Scanning Electron Microscope was used to study the surface morphology of the Embelin loaded phytosome complex.

In-vitro entrapment efficiency of Embelin loaded phytosome complex

UV-Visible spectrophotometer method of analysis was used for the determination of the Embelin loaded phytosome complex formulations. A known quantity of Embelin loaded phytosome complex (equivalent to 10 mg of embelin) was taken in a beaker 50 ml methanol was added into the beaker. The contents of beaker were stirred for 4 h and then allowed to stand at room temperature for one hour. Supernatant clear liquid was removed from beaker and cen-trifuged at 2000 rpm for 15 min. 0.45 μ Whatman filter paper was used for the filtration of centrifuged liquid. Absorbance of this liquid was measured by of UV- Visible double beam spectrophotometer (Shimadzu-1800, Japan) at 288.7nm, after suitable dilution. All measurements were performed in triplicate. . Drug entrapment efficiency was determined by using the following equation.

Drug entrapment efficiency (%)=(Total amount of drug-Amount of free drug)/(Total amount of drug) x 100

In vitro release profiles of Embelin from Embelin loaded phytosome complex

In-vitro drug release (dissolution) study of each Embelin loaded phytosome complex was determined with the help of a USP type I, six station dissolution test apparatus. Basket of dissolution test apparatus was filled with 900 ml of pH 6.8 phos¬phate buffer. The test was performed at 100 rpm and at 37 ± 2°C. A weighed amount of Embelin loaded phytosome complex 10 mg of Embelin were dispersed dissolution medium. 5 ml of sample was withdrawn at regular predetermined time interval (0, 30, 60, 120, 180, 240, 300, 360, 420, 480, 600, 720 m). Sample was filtered with the help of Whatman filter paper. Equal volume was replenished with fresh phos¬phate buffer each time to maintain sink condition. The collected samples were suitably diluted with phos¬phate buffer and assayed by UV-VIS spectrophotometer at 288.7 nm against phos¬phate buffer as blank to determine the concentration of Embelin present in the dissolution medium.

Drug release kinetic studies of Embelin loaded phytosome complex

To analyze the mechanism of drug release from the floating microspheres, in vitro dissolution data were fitted in Zero order rate kinetics, First order rate kinetics and Higuchi’s mode

Results and Discussion

Drug-excipients compatibility study

Physical compatibility test were performed for selection of excipients for the preparation of phytosomes. FTIR spectroscopy and Differential Scanning Calorimetry (DSC) method of analysis were used for this study.

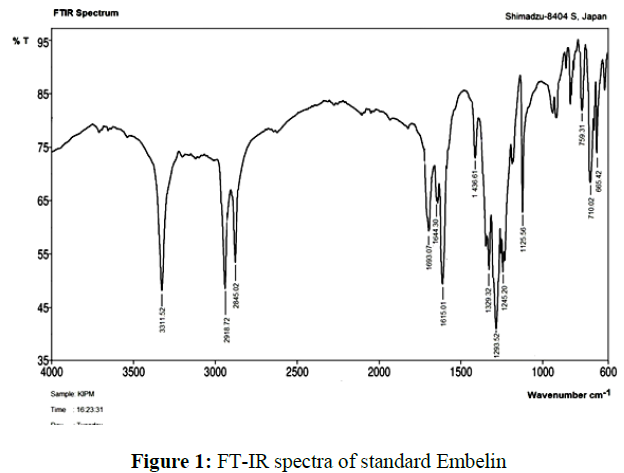

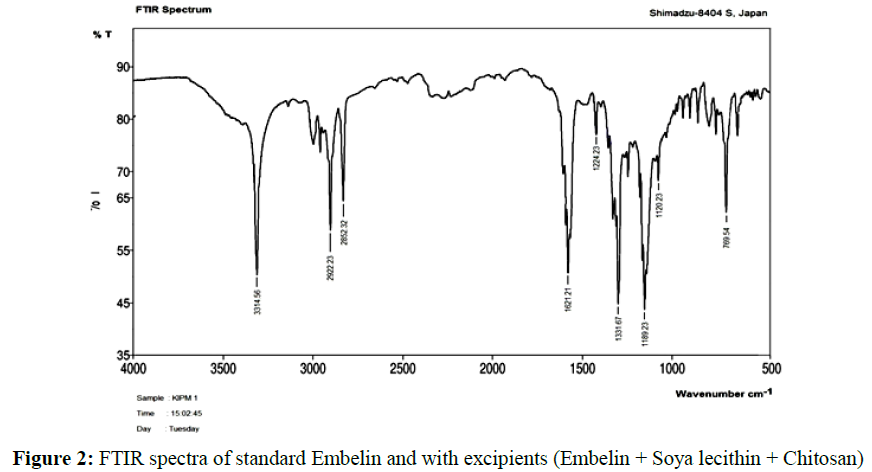

IR-spectra of standard Embelin and with excipients (soya lecithin + chitosan) were compared. Spectral analysis reveals that there were no interaction between standard Embelin and excipients used in the preparation of phytosomes (Table 2, Fig. 1 and 2).

| Characteristic stretching and bending | Standard Embelin | Embelin+Soya lecithin+Chitosan |

|---|---|---|

| Wave numbers (cm-1) | ||

| C-O Stretching | 1125.56 | 1120.23 |

| C=O Stretching | 1615.01 | 1621.21 |

| C-H Stretching (methyl) | 2845.02 | 2852.32 |

| C-H Stretching (aromatic) | 2918.72 | 2922.23 |

| O-H (Stretching OH group) | 3311.52 | 3314.56 |

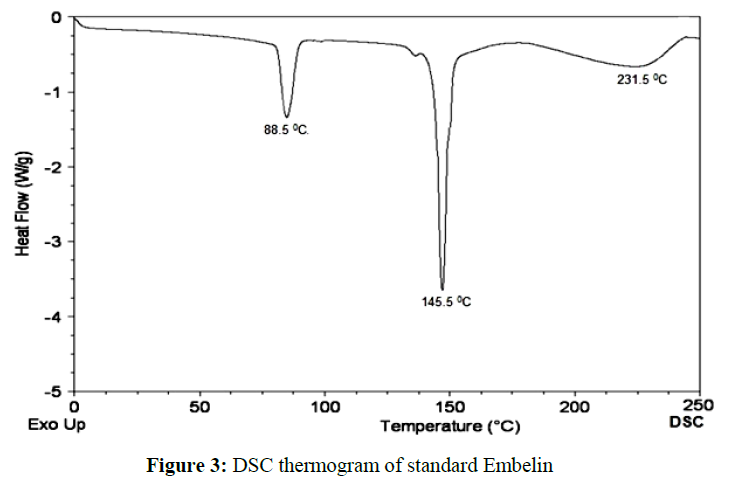

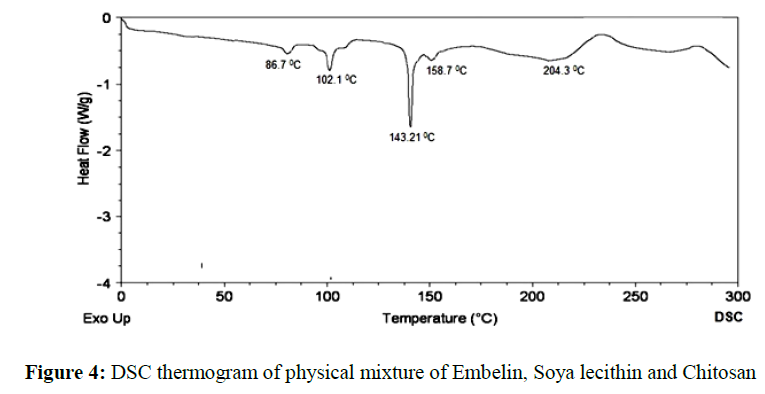

Shimadzu DSC (DSC-60, Japan) was also used for compatibility study of standard Embelin with excipients used in formulation. DSC of standard Embelin showed three endothermic peaks at 88.50°C, 144.50°C and 231.50°C which represent loss of water, melting point and decomposition respectively (Figure 3). Three endothermic peaks at 102.10°C, 143.21°C and 158.7°C were observed for chitosan, Embelin and soya lecithin in the physical mixture of Embelin, soya lecithin and chitosan (Figure 4).

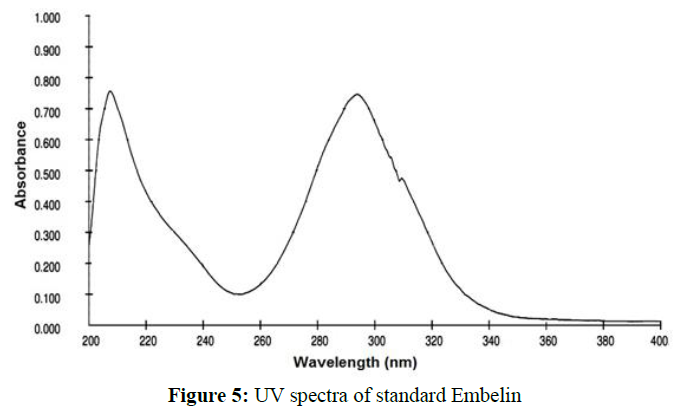

Determination of λmax of standard Embelin and preparation of calibration curve of standard Embelin The λmax of standard Embelin was measured by UV-VIS double beam spectrophotometer (Shimadzu-1800, Japan). The λmax of standard Embelin was found to be of 288.7 nm (Figure 5)

Standard calibration curve was prepared by plotting absorbance data of standard Embelin against various concentrations in methanol (Figure 6).

Evaluation of Embelin loaded phytosome complex

Percentage yield, Particle size determination and In-vitro entrapment efficiency of Embelin loaded phytosome complex

The percentage yields were calculated for each properly dried Embelin loaded phytosome complex formulation. Formulation EMBP4 showed highest percentage yield (86.20 ± 0.53) while formulation EMBP6 showed lowest percentage yield (60.00 ± 0.33) (Table 3).

After performing the particle size determination, the average diameter of dried Embelin loaded phytosome complex was found to be varies from 345.45 ±1.231 nm to 485.32 ± 1.213 nm as presented in Table 6.7. Formulation EMBP5 exhibits lowest 345.45 ±1.231 diameter (Table 3).

The entrapment efficiency of Embelin loaded phytosome complex varies from 64.99 ± 1.546 to 81.78 ± 1.151% as shown in Table 6.7. It was observed that Embelin loaded phytosome complex formulation (EMBP5) exhibits highest of 81.78 ± 1.151% entrapment efficiency (Table 3).

| S. No. | Formulations | Percentage yield | Mean diameter of Embelin loaded phytosome complex (nm) | Entrapment efficiency (%) |

|---|---|---|---|---|

| 1 | EMBP1 | 65.80 ± 0.21 | 485.32 ± 1.213 | 73.31 ± 1.323 |

| 2 | EMBP2 | 74.60 ± 0.37 | 387.47 ± 1.373 | 77.62 ± 1.034 |

| 3 | EMBP3 | 70.53 ± 0.33 | 436.37 ± 2.361 | 64.99 ± 1.546 |

| 4 | EMBP4 | 76.32 ± 0.53 | 456.26 ± 1.761 | 74.23 ±1.832 |

| 5 | EMBP5 | 86.20 ± 0.67 | 345.45 ±1.231 | 81.78 ± 1.151 |

| 6 | EMBP6 | 60.00 ± 0.33 | 451.39 ±7.316 | 66.69 ± 1.321 |

SEM analysis

SEM photomicrographs give us brief information regarding the solid state properties and surface morphology of Embelin loaded phytosome complex. SEM photomicrographs of optimized formulation (EMBP5) of Embelin loaded phytosome complex showed that the phytosomes are less spherical with smooth and rough surface and slightly aggregated. The phytosomes generally appeared as either individual body or assemblies of non-fused phytosomes (Fig. 7 and 8).

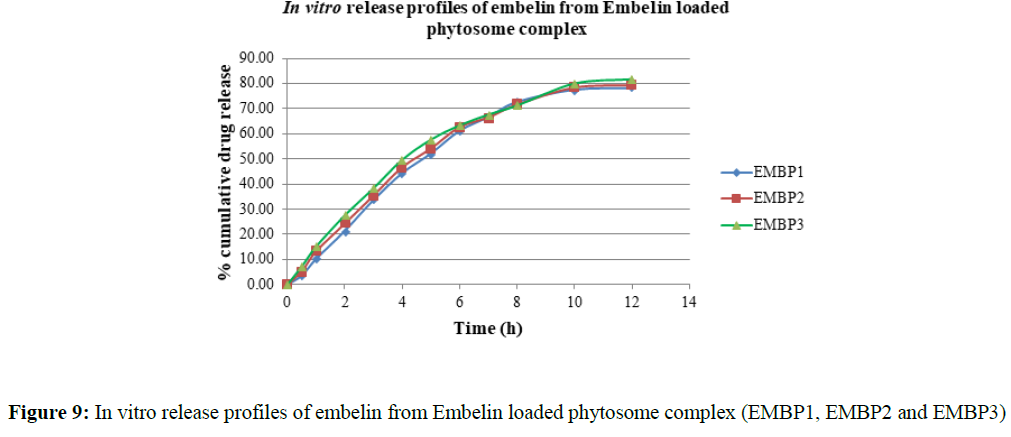

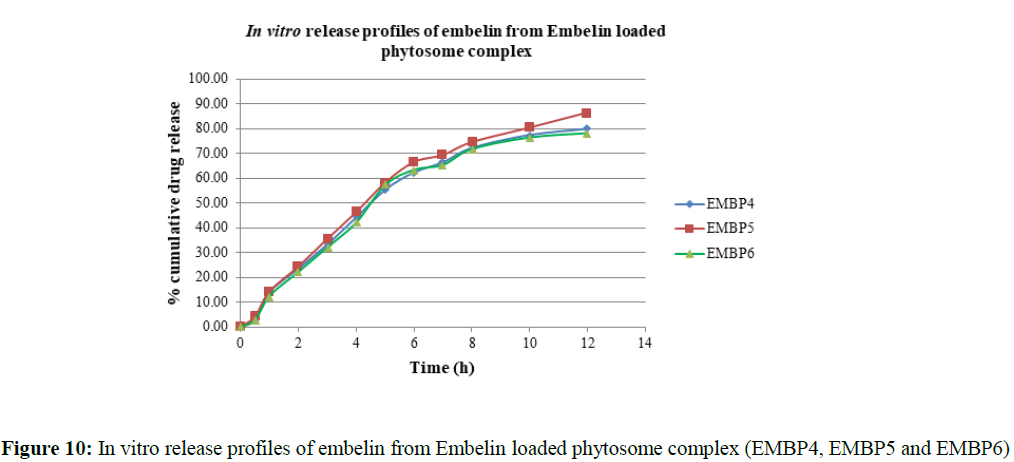

In-vitro release profiles of embelin from Embelin loaded phytosome complex

A USP type I, six station dissolution test apparatus was used for the determination of in-vitro release profiles of embelin from Embelin loaded phytosome complex. At specified time intervals, sample aliquots were withdrawn and analyzed spectrophotometrically at 288.7nm. The results of the in-vitro dissolution studies shows controlled and predictable manner (Table 4) and (Fig. 9 and 10).

| Time (h) | Cumulative percentage (%) of drug release | |||||

|---|---|---|---|---|---|---|

| EMBP1 | EMBP2 | EMBP3 | EMBP4 | EMBP5 | EMBP6 | |

| 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 0.5 | 3.63 | 5.33 | 7.21 | 3.21 | 4.32 | 2.78 |

| 1 | 10.25 | 13.26 | 15.13 | 14.12 | 14.32 | 12.54 |

| 2 | 21.43 | 24.31 | 27.58 | 23.54 | 24.43 | 22.24 |

| 3 | 33.71 | 35.48 | 38.36 | 33.24 | 35.54 | 32.12 |

| 4 | 44.43 | 46.71 | 49.71 | 44.21 | 46.35 | 42.12 |

| 5 | 52.24 | 54.21 | 57.72 | 55.35 | 58.21 | 57.22 |

| 6 | 61.27 | 62.74 | 63.43 | 62.35 | 66.55 | 63.41 |

| 7 | 66.74 | 66.56 | 67.67 | 66.45 | 69.4 | 65.35 |

| 8 | 72.72 | 71.64 | 71.31 | 72.22 | 74.58 | 71.77 |

| 10 | 77.56 | 78.44 | 80.06 | 77.45 | 80.45 | 76.42 |

| 12 | 78.23 | 79.32 | 81.74 | 79.92 | 86.52 | 78.21 |

Drug release kinetic studies of Embelin loaded phytosome complex

Different mathematical models may be applied for describing the kinetics of the drug release process from dosage forms. The in vitro data obtained was fitted into Zero order rate kinetics, First order rate kinetics and Higuchi’s model. The kinetics of release from formulations were determined by finding the best fit of the release data to zero order, first order and Higuchi’s model. Initial drug releases from all formulations were significantly high due to the dissolution of surface adhered drug. As the time increases the release was slow due to the diffusion process.

From the data (Table 5), the release of embelin from Embelin loaded phytosome complex was by fickian diffusion mechanism and followed first order kinetics (concentration dependant).

| Mechanism of drug release | EMBP1 | EMBP2 | EMBP3 | EMBP4 | EMBP5 | EMBP6 |

|---|---|---|---|---|---|---|

| Regression co-efficient (R2) values | ||||||

| Zero order drug release kinetics | 0.916 | 0.9137 | 0.9091 | 0.9169 | 0.9248 | 0.9065 |

| First order drug release kinetics | 0.9819 | 0.9887 | 0.975 | 0.9838 | 0.9956 | 0.9708 |

| Higuchi’s Model diffusion release kinetics | 0.9616 | 0.9712 | 0.9784 | 0.9578 | 0.9707 | 0.9578 |

| Best fit model | First order and Higuchi’s Model | First order and Higuchi’s Model | First order and Higuchi’s Model | First order and Higuchi’s Model | First order and Higuchi’s Model | First order and Higuchi’s Model |

Conclusion

Embelin was one of active constituents of Embelia ribes Burm. f. Embelin has been reported to possess many pharmacological effects. Phytosomes study can increase therapeutic efficacy, decrease the frequency of administration. Embelin loaded phytosome complex were formulated by anti-solvent precipitation method and Rotary evaporation technique. Total six formulations coded as EMBP1, EMBP2, EMBP3, EMBP4, EMBP5 and EMBP6 of Embelin loaded phytosome were prepared. Among six formulations, the Formulation EMBP5 well optimized. EMBP5 exhibits lowest 345.45 ±1.231 diameter. The entrapment efficiency of Embelin loaded phytosome complex varies from 64.99 ± 1.546 to 81.78 ± 1.151%. Embelin loaded phytosome complex formulation (EMBP5) exhibits highest of 81.78 ± 1.151% entrapment efficiency. SEM photomicrographs of optimized formulation (EMBP5) of Embelin loaded phytosome complex showed that the phytosomes are less spherical with smooth and rough surface and slightly aggregated. In vitro dissolution study of phytosome extended release pattern show 12 hr, 86.52% release. Different mathematical models may be applied for describing the kinetics of the drug release process from dosage forms. From the data, the release of embelin from Embelin loaded phytosome complex was by fickian diffusion mechanism and followed first order kinetics (concentration dependant).On the basis of above obsrvation, it has been presumed that Embelin loaded phytosome complex serve as a useful novel drug delivery system and provide more therapeutic efficacy than conventional plant extracts.

References

- Kidd PM. Altern Med Rev, 2009, 14(3):226–46.

- Manach C ,Scalbert A ,Morand C ,Rémésy C ,Jiménez L. Am J Clin Nutr. 2004, 79(5):727–47.

- Teng Z ,Yuan C ,Zhang F. PLoS One, 2012, 7(1):e29647.

- Manach C, Scalbert A, Morand C, Rémésy C, Jiménez L. Am J Clin Nutr. 2004, 79(5):727–47.

- Ting Y ,Jiang Y ,Ho CT ,Huang Q. J Funct Foods. 2014, 7:112–28.