Research Article - Der Pharma Chemica ( 2022) Volume 14, Issue 6

Fabrication and Evaluation of Modified Release Salbutamol Tablet in Tablet Dosage Comprising Novel Polymeric Coating

Nandhakumar L1*, Chandrasekaran S2, Mohammed Maideen K3 and Senthil Raja M42Quality Assurance, Par Formulations Pvt Ltd, Pudupakkam, Kelambakkam, Chennai, Tamilnadu, India

3Formulation and development, Medreich R&D Pvt Ltd, Bommasandra Industrial area, Anekal Taulk, Bengaluru, Karnataka, India

4Department of Pharmaceutical Chemistry, Kasthooribha Gandhi Pharmacy College, Rasipuram, Namakkal, Tamilnadu, India

Nandhakumar L, Department of Pharmaceutics, Kasthooribha Gandhi Pharmacy College, Rasipuram, Namakkal, Tamilnadu, India, Email: drndkumar12@gmail.com

Received: 18-May-2022, Manuscript No. dpc-22-64182; Editor assigned: 20-May-2022, Pre QC No. dpc-22-64182; Reviewed: 03-Jun-2022, QC No. dpc-22-64182; Revised: 06-Jun-2022, Manuscript No. dpc-22-64182; Published: 14-Jun-2022, DOI: 10.4172/0975-413X.14.6.18-23

Abstract

In recent times, modified drug dosage forms offers manifold merits, such as maintain or sustaining constant drug level at the site of action, prevention of peak concentration fluctuation, reduction in dose of drug, reduced dosage frequency, averting the side effects and which in turn availing improved patient compliance. Hence in this current study, an effort has been made to develop a modified drug release by using tablet in tablet technique encompassing novel polymeric coating by using natural and synthetic polymers with Salbutamol sulphate. The inner core tablets were prepared by using direct compression method. It has been observed that the formulation F7 was selected for press coat by using different polymers like HPMC, Ethyl cellulose, Xanthum gum and Guar gum in different ratios among which 1part of Xanthum gum and 1part of Guar gum was optimized based on the lag time (20.75% in 4 hours) and percent of drug release and also further evaluated.

Keywords

Modified release tablets; Novel polymer coating; Salbutamol sulphate; Tablet in tablet; Controlled drug delivery

INTRODUCTION

The second-generation drug delivery goal has been the perfection of continuous, constant rate (zero order) delivery of bioactive agents. However, living organisms are not zero order in their requirement or response to drugs. They are predictable resonating dynamic systems, which require different amounts of drug at predictably different times within the circadian cycle in order to maximize desired and minimize undesired drug effects. Due to advances in chronobiology, chronopharmacology and global market constraints, the traditional goal of pharmaceutics (e.g. design drug delivery system with a constant drug release rate) is becoming obsolete. However, the major bottleneck in the development of drug delivery systems that match circadian rhythms (chronopharmaceutical drug delivery system: ChrDDS) may be the availability of appropriate technology. The diseases currently targeted for chronopharmaceutical formulations are those for which there are enough scientific backgrounds to justify ChrDDS compared to the conventional drug administration approach. These include asthma, arthritis, duodenal ulcer, cancer, diabetes, cardiovascular diseases, hypercholesterolemia, ulcer and neurological diseases [1, 9].

If the organization in time of living system including man is borne in mind, it is easy to conceive that not only must the right amount of the right substance be at right place but also this must occur at the right time. In the last decade numerous studies in animals as well as clinical studies have provided convincing evidence, that the pharmacokinetics &/or the drug’s effects -side effects can be modified by the circadian time &/or the timing of drug application within 24 hrs of a day [3].

Circadian variation in pain, stiffness and manual and manual dexterity in patients with osteo and rheumatoid arthritis have been studied and has implication for timing antirheumatide drug treatment.4 Morning stiffness associated with pain at the time of awakening is a diagnostic criterion of the rheumatoid arthritis and these clinical circadian symptoms are supposed to be outcome of altered functioning of hypothalamic pitutary adrenocortical axis. Chronopharmacotherapy for rheumatoid arthritis has been recommended to ensure that the highest blood levels of the drug coincide with peak pain and stiffness [5]. A pulsatile drug delivery system that can be administered at night (before sleep) but that release drug in early morning would be a promising chronopharmaceutic system [10-15].

Drug targeting to colon would prove useful where intentional delayed drug absorption is desired from therapeutic point of view in the treatment of disease that have peak symptoms inthe early morning such as nocturnal asthma, angina, arthritis [16-24].

Some orally administered drugs (e.g. Diclofenac, Theophyllin, IbuprofenIsosorbide) may exhibit poor uptake in the upper regions of GIT or degrade in the presence of GIT enzymes. Better bioavailability can be achieved through colon- specific drug delivery. Colonic targeting is also advantageous where delay in systemic absorption is therapeutically desirable [25-31].

Circadian rhythms and their implications

Circadian rhythms are self-sustaining, endogenous oscillation, exhibiting periodicities of about one day or 24 hours. Normally, circadian rhythms are synchronized according to the bodys pacemaker clock, located in the suprachiasmic nucleus of the hypothalamus.

The physiology and biochemistry of human being is not constant during the 24 hours, but variable in a predictable manner as defined by the timing of the peak and through of each of the bodys circadian processes and functions. The peak in the rhythms of basal gastric and secretion, white blood cells (WBC), lymphocytes, prolactin, melatonin, eosinophils, adrenal corticotrophic hormone (ACTH), follicle stimulating hormone (FSH), and leuteinizing hormone (LH), is manifested at specific times during the nocturnal sleep span [32-41]. The peak in serum cortisol, aldosterone, testosterone plus platelet adhesiveness and blood viscosity follows later during the initial hours of diurnal activity.

MATERIAL AND METHODS

Formulation of core tablets by direct compression

The inner core tablets were prepared by using direct compression method. The powder mixtures of Salbutamol sulphate, microcrystalline cellulose (MCC, Avicel PH-102), cross-carmellose sodium (Ac-Di-Sol) ,SSG, crospovidone, starch ingredients were dry blended for 20 min, followed by addition of Magnesium Stearate [42-48]. The mixtures were then further blended for 10 min., 180mg of resultant powder blend was manually compressed using KBr hydraulic press at a pressure of 1 ton, with a 8mm punch and die to obtain the core tablet (Table 1).

| Press coat | Pr1(mg) | Pr2(mg) | Pr3(mg) | Pr4(mg) | Pr5(mg) |

|---|---|---|---|---|---|

| >HPMC | 200 | 300 | -- | 400 | -- |

| Ethyl cellulose | 200 | 100 | -- | -- | -- |

| Xanthum gum | -- | -- | 300 | -- | 200 |

| Guar gum | -- | -- | 100 | -- | 200 |

| Total wt(mg) | 400 | 400 | 400 | 400 | 400 |

Formulation of mixed blend for barrier layer

The various formulation compositions containing HPMC, Ethyl cellulose, Xanthum gum and Guar gum. Different compositions were weighed dry blended at about 10 min. and used as press-coating material to prepare press-coated pulsatile tablets respectively by direct compression method.

Stability Studies

The stability study of the formulations was carried out according to ICH guidelines at 40 ± 2º C/75 ± 5 % RH for three months by storing the samples in stability chamber (Lab-care, Mumbai).

The purpose of stability testing is to provide evidence of the quality of the drug substance or drug product, and how it varies with time under the influence of a variety of environmental conditions (heat, humidity, light, air etc).

The final formulation was packed in suitable packing like blister and strip packs and then they will be kept at different temperature, humidity conditions and the samples will be analyzed for their physical and chemical properties.

RESULTS AND DISCUSSION

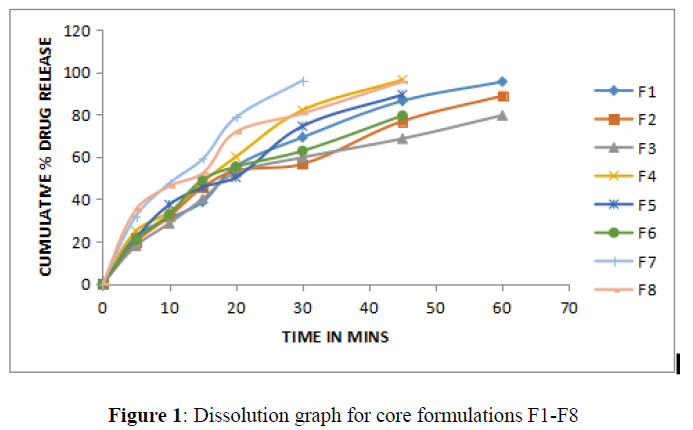

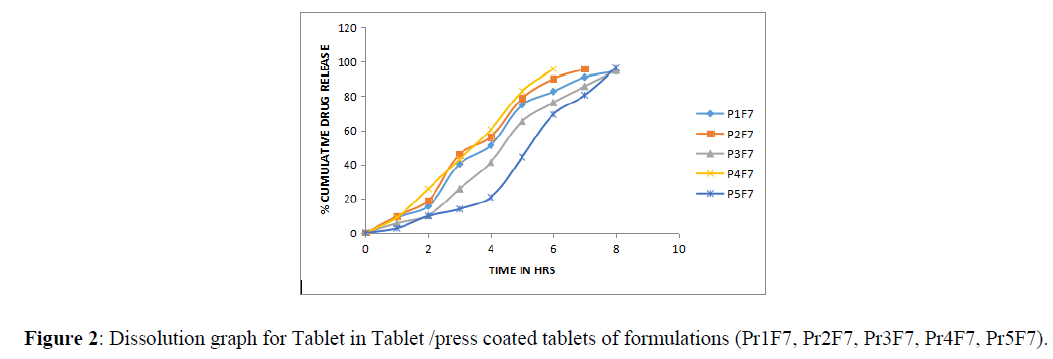

Pre formulation parameters (Tables 2-6) (Figure 1,2)

| Formulation code | Bulk density (gm/mL) | Tapped density (gm/mL) | Compressibility index (%) | Hausner’s ratio | Flow property |

|---|---|---|---|---|---|

| >Fr1 | 0.46±0.045 | 0.49 ± 0.07 | 12.19±0.6 | 1.12±0.04 | Very good |

| Fr2 | 0.45±0.044 | 0.51 ± 0.09 | 12.01±0.8 | 1.17±0.08 | Very good |

| Fr3 | 0.44±0.045 | 0.50 ± 0.04 | 15.02±0.1 | 1.16±0.06 | Very good |

| Fr4 | 0.45±0.044 | 0.50± 0.01 | 16.01±0.6 | 1.17±0.08 | Very good |

| Fr5 | 0.46±0.045 | 0.50 ± 0.04 | 13.43±0.8 | 1.14±0.09 | Very good |

| Fr6 | 0.50±0.045 | 0.60 ± 0.04 | 14.38±0.8 | 1.16±0.09 | Very good |

| Fr7 | 0.52±0.02 | 0.63±0.05 | 17.95±0.05 | 1.19±0.05 | Very good |

| Fr8 | 0.53±0.03 | 0.64±0.05 | 17.24±0.07 | 1.18±0.06 | Very good |

| S. No | Physical parameter | Fr 1 | Fr 2 | Fr 3 | Fr 4 | Fr 5 | Fr 6 | Fr7 | Fr 8 |

|---|---|---|---|---|---|---|---|---|---|

| 1 | Weight (mg) | 147 | 148 | 148 | 152 | 151 | 150 | 152 | 150 |

| 2 | Hardness | 4.3 | 4.1 | 4.2 | 4.2 | 4.1 | 4.1 | 4.1 | 4.2 |

| (Kg/cm2) | |||||||||

| 3 | Thickness | 3.05 | 3.02 | 3.22 | 3.5 | 3.26 | 3.51 | 3.4 | 3.2 |

| (mm) | |||||||||

| 4 | Friability % | 0.5 | 0.51 | 0.6 | 0.51 | 0.63 | 0.57 | 0.6 | 0.5 |

| 5 | Disintegration time | 3 min 50sec | 3min 32 sec | 2min | 2min20sec | 2min 15sec sec | 2min | 1min | 1min 20 sec |

| 15 sec |

| Time (min) | Fr1 | Fr2 | Fr3 | Fr4 | Fr5 | Fr6 | Fr7 | Fr8 |

|---|---|---|---|---|---|---|---|---|

| >5 | 22.5 | 19.8 | 17.9 | 25 | 21.62 | 20.8 | 32 | 35.1 |

| 10 | 30.82 | 31.8 | 28.6 | 34 | 37.4 | 32.83 | 47.43 | 46.14 |

| 15 | 38.7 | 45.5 | 40.1 | 48 | 45.6 | 49.25 | 58.98 | 52.22 |

| 20 | 55.5 | 53.4 | 52.5 | 60 | 50.3 | 55.33 | 78.6 | 71.74 |

| 30 | 69.2 | 56.6 | 59.7 | 82 | 74.45 | 62.8 | 96.1 | 80.5 |

| 45 | 86.4 | 76.8 | 68.6 | 96.4 | 89.36 | 79.5 | -- | 95.5 |

| 60 | 95.5 | 88.8 | 79.6 | -- | -- | -- | -- | -- |

| S.No | Physical parameter | Pr1F7 | Pr2F7 | Pr3F7 | Pr4F7 | Pr5F7 |

|---|---|---|---|---|---|---|

| 1 | Weight (mg) | 552 | 551 | 553 | 550 | 550 |

| 2 | Hardness | 7.5 | 7.7 | 7.8 | 7.2 | 7.6 |

| (Kg/cm2) | ||||||

| 3 | Thickness | 2.5 | 2.6 | 2.4 | 2.4 | 2.5 |

| (mm) | ||||||

| 4 | Friability % | 0.56 | 0.55 | 0.62 | 0.54 | 0.62 |

| Time (hrs) | Formulation code | ||||

|---|---|---|---|---|---|

| Pr1F7 | Pr2F7 | Pr3F7 | Pr4F7 | Pr5F7 | |

| >1 | 9.01 | 9.62 | 6.02 | 9.15 | 2.73 |

| 2 | 15.45 | 18.72 | 10.2 | 25.65 | 9.77 |

| 3 | 40.12 | 46.08 | 26.05 | 42.98 | 14.81 |

| 4 | 50.21 | 55.92 | 41.35 | 60.45 | 21.33 |

| 5 | 72.85 | 79.06 | 64.32 | 83.8 | 45.35 |

| 6 | 81.66 | 90.1 | 76.32 | 95.64 | 70.41 |

| 7 | 91.74 | 95.53 | 85.62 | -- | 80.6 |

| 8 | 93.22 | -- | 94.65 | -- | 96.4 |

Based on the drug release within the required time period F7 was optimized and further formulated for press coating.

From the above core formulations F7 was selected for press coat by using different polymers like HPMC, Ethyl cellulose, Xanthum gum and Guar gum in different ratios among which 1part of Xanthum gum and 1part of Guar gum was optimized based on the lag time(20.75% in 4 hours) and percent of drug release and also further evaluated (Table 7).

| Cumulative % drug release during 8 Hrs. | |||

|---|---|---|---|

| Sampling interval | 25ºC/60% RH | 30ºC/65% RH | 40ºC/75% RH |

| >0 Days | 96.5 | 96.5 | 96.2 |

| 30Days | 96.2 | 96.3 | 96.1 |

| 60 Days | 95.3 | 95.6 | 95.82 |

| 90 Days | 95.1 | 95.2 | 94.3 |

Stability studies of the formulation Pr5F7 of Salbutamol press coated were carried out to determine the effect of formulation additives on the stability of the drug and also to determine the physical stability of the formulation. The stability studies were carried out at 25ºC/60%RH, 30 ºC/65% RH and 40ºC/75% RH for 90 days. There was no significant change in the physical property and percent of drug release was within the limits±4 during 8hour during the stability period.

CONCLUSION

At this juncture, from the research results it can be concluded that, Formulated tablets gave satisfactory results for various physicochemical parameters like hardness, friability, thickness, weight variation and content uniformity. Xanthum gum and Guar gum (1:1) has predominant effect on the lag time, while also shows significant effect on drug release. Hence it is conducive to prepare the formulation of novel tablet in tablet formulation with novel polymer coating containing β2-adrenergic receptor agonists.

References

- Satwara RS, Patel PK and Shaikh F. . Int J Pharm Tech Res. 2012, 4(2): p.765–777.

- Feuvray D, Heart Metab. 2009, 44: p.3-4.

- Bălan H. J Intern Med. 2008, 46(4): p.269–274.

- Takeda N and Maemura K. J Cardiol. 2011, 57: p.259-256.

- Smith DHG. Am J Hypertens. 2001, 14: p.296S–301S.

- Shigehiro O. Adv Drug Deliv Rev. 2010, 62: p.859-875.

- Smith D, Neutel JM and Weber MA. Am J Hypertens. 2001, 14: p.14-19.

- Seshasayan A, Sreenivasa RB, Prasanna R, et al., J Pharma Sci. 2007, p. 337-339.

- Zahirul Khan MI, Zeljko P and Nevenka K. J Control Rel. 1999, 58: p. 215-222.

- Howard NES, Clive GW, Peter GW et al., Int J Pharm. 2002, 236: p.27- 34.

- Sengodan T, Jagdish C and Mithun B et al., J drug deliv ther. 2014, 4(1): p. 5-14.

- Libo Y, James SC and Joseph AF. Int J Pharm. 2002, 235: p.1-15.

- Bera K, Khanam J, Mohanraj KP et al., J Microencapsul. 2014, 31(3): p. 220-229.

- Ying-huan Li and Jia-bi Zhu. J Control Rel. 2004, 50: p.111-122.

- Gurudeeban S, Satyavani K, Ramanathan T et al., J Med Sci. 2015, 15(1): p. 18-24.

- Jonathan CDS, Alistair CR, Walter K et al. J Control Rel. 2003, 92: p.341-347.

- Matiholimath VS, Dandagi PM, Jain SS et al., Int J Pharm. 2007, 328: p.49-56.

- Jagadish Ci, Vishali R, Sengodan T et al., Int J Pharm Pharm. 2016, 6(2): p.128-137.

- Abraham S and Srinath MS. Indian J Pharm Sci. 69(1): p.18-23.

- Sharma S and Pawar SA. Int J Pharm 2006, 313: p. 150-158.

- Gupta BP, Thakur N, Jain NP etal., J Pharm Pharm Sci. 2010, p. 571-588.

- Palsson BO, Wheatley TA and Dressman JB. J Cont Release. 1990, 14: p. 203-213.

- Ghebre-Sellassie I. Pellets: A General Overview. Ghebre-Sellassie, I. (Ed.) Pharmaceutical Pelletization Technology, Marcel Dekker Inc. New York. 1989, p. 1-13.

- Schmidt C and Kleinebudde P. Chem Pharm Bull. 1999, 47(3): p.405-412.

- Steckel H and Nogly MF. Eur J Pharm and Biopharm. 2003, 57: p.107-114.

- Sinha VR, Agrawal MK and Bhinge JR. Current drug delivery. 2005, 2: p.1-8.

- Newton A, Podczeck F, Alderborn G et al., Int J Pharm. 2002, 239(1): p.171-178.

- Zezhi JS, Moralesi L, Diaz S et al., AAPS Pharm SciTech. 2002, 3(2): p.1-9.

- Boldmeier R and Pearnchob N. Int J Pharm. 2003, 268(2): p.1-11.

- Weijia Z and Mcginity J. Drug Dev Ind Pharm. 2003, 29(3): p.357-366.

- Wei J, Mingfeng Q, Xia S et al., Advances in Therapy. 2004, (21): p. 238-248.

- Rahman N, Yuen KH and Woei WJ. Acta Pharmaceutica Turcica. 2005, (47): p.199-207.

- Neau SH, Chow MY and Durrani M. Int J Pharm. 1996, 131: p. 47- 55.

- Bommareddy GS, Paker LS, Saripella K. et al., Int J Pharm. 2006, 321: p. 62-71.

- Abrahamsson B, Alpsten M, Jonsson UE et al., Int J Pharm. 2000, 140: p. 229-235.

- Thrombre AG. Drug Discovery Today. 2005, 10: p. 1159 -1166.

- Colombo P, Bettini RS and Peppas NA. Pharm Sci Tech Today. 2001, 3: p. 198-204.

- Eriksen S, The Theory and Practice of Industrial Pharmacy.1998, p. 40z.

- FDA, 1997. ICH Q1C Stability Testing for New Dosage Forms. Guidance for industry.

- US Department of Health and Human Services Food and Drug Administration Center for Drug Evaluation and Research, Center for Biologics Evaluation and Research, ICH.

- Reza MS, Quadir MA and Haider SS. J pharm Sci. 2003, 6(2): p. 282-91.

- Alderm DA. Ind J Pharm Technol. 1984, 5: p. 1-5.

- Fessi H. Int J Pharm. 1978, 1: p. 27-32.

- Peppas NA and Khare AR. Adv Drug Delive Revie. 1993, 11: p. 1-35.

- Peppas NA.Pharm Aceta Helv. 1985, 60(4): p.110-111

- Gao P, Naxon PR and Skoug JW. Pharm Res. 1995, 12(7): p. 965-971.

- Tahara K, Yamamoto k and Nishihata T. J Contr Rel.1995, 35: p. 59-66.

- Wan LC, Heng PS and Wong LF. Int J Pharm.1991: 73: p.111-116.

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed atGoogle ScholarCrossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref