Research Article - Der Pharma Chemica ( 2024) Volume 16, Issue 3

Extraction of Dyes from Parts of the Plants and their Phytochemical Screening

S. Sashikala*, S. Sharmila and A. Nousheen IffathS. Sashikala, Department of Chemistry, D.K.M College for Women, Vellore, Tamil Nadu, India, Email: sashikala1976@gmail.com

Received: 29-Apr-2024, Manuscript No. DPC-24-133406; Editor assigned: 02-May-2024, Pre QC No. DPC-24-133406 (PQ); Reviewed: 16-May-2024, QC No. DPC-24-133406; Revised: 23-May-2024, Manuscript No. DPC-24-133406 (R); Published: 27-Jun-2024, DOI: 10.4172/0975-413X.16.3.321-329

Abstract

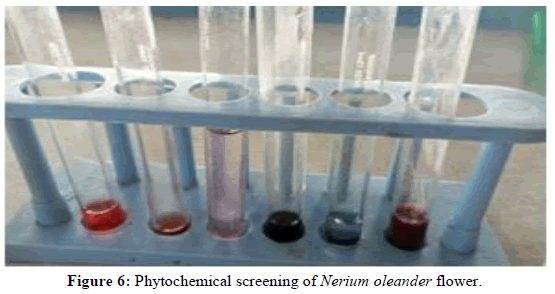

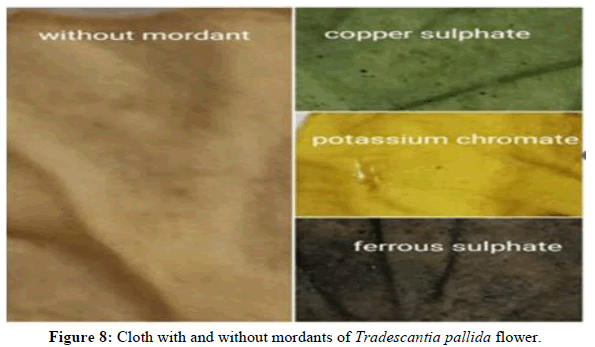

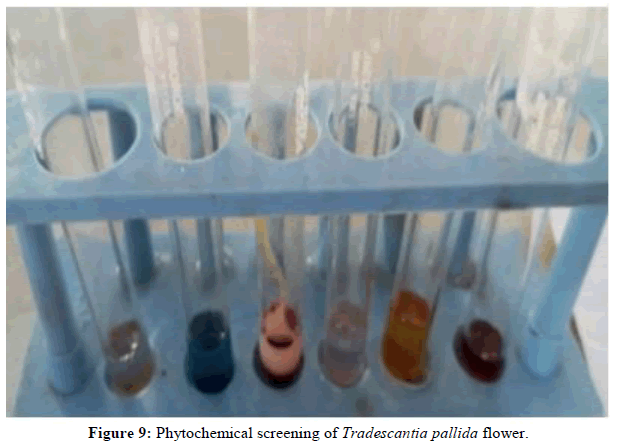

The primary goal of obtaining dyes from natural plant sources is to prevent pollution of the environment. Any color, pigment or material originating from organic materials plants, animals or minerals are considered as a natural dye, since it is a sustainable bio resource with no negative influence on the environment. The oldest known kind of dyeing is arguably the use of natural dyes. Nowadays, natural dyes are widely used in the textile sector because synthetic colors are harmful to human skin. Much study is being done globally on the use of natural dyes in the textile industry in light of the current worldwide concern about the usage of eco-friendly and biodegradable products. They have been utilized for coloring food items, textiles, natural protein fibers like wool, silk, cotton and leather. Natural dye was initially used by humans as a thought tool to create artwork that reflected both their environment and themselves. Synthetic dyes have effluent issues not only when they are used in the textile industry but also when they are made and may even arise while synthesizing other raw materials and intermediates. After synthetic dyes were discovered in 1856, the usage of natural dyes for textile dyeing was greatly reduced. Natural dyes have been used to color fabrics since ancient times, the discovery of mauve colorant in the 19th century led to the replacement of natural dyes with synthetic ones. Naturally occurring dyes have become a significant substitute for artificial dyes. Furthermore, the plant dyes might serve as a substitute for synthetic dyes when it comes to dying natural cotton fiber. In order to verify the plant dyes' qualities and introduce them into textiles more quickly and efficiently, this process is used to first identify plants from which dyes can be derived. In the present study, the phytochemical screening was carried from natural dyes which were obtained from different plant parts, namely Ixora Coccinea flower (pink), Nerium oleander flower (red), Tradescantia pallida flower, Portulaca oleracea, Cissus qudrangularis stem and Celosia cristata stem. The extracted dyes were categorized for different chemical groups like alkaloids, flavonoids, tannins, saponins, carbohydrates, amino acids etc., using various chemical reactions.

Keywords

Natural dyes; Biodegradable; Phytochemical screening; Ixora Coccinea flower (pink); Nerium Oleander flower (red); Tradescantia pallida flower; Portulaca oleracea; Cissus quadrangularis stem; Celosia cristata stem

Introduction

The utilization of plants for dyes is considered crucial. Lately, there has been a significant increase in interest towards natural dyes, mainly due to the strict environmental regulations imposed by numerous countries in response to the harmful effects and allergic reactions caused by synthetic dyes. As a result, with a distinct lowering in synthetic dyestuff costs, the natural dyes were virtually unused at the beginning of twentieth century (Kumaresan, et. al). Currently, in the majority of nations, natural dyeing is predominantly carried out as a traditional craft, while synthetic dyes have become the norm in all industrial dyeing procedures. However, with the worldwide concern over the use of eco-friendly and biodegradable materials, the use of natural dyes has once again gained interest (Agarwal A, et al).

Dyeing can be conducted in an alkaline, acidic or neutral bath. Numerous studies have been published on various techniques of mordanting for different types of fibres, including cellulosic, protenic and synthetic fibers, when dyeing with natural dyes. By utilizing different mordants, a wide range of shades can be achieved, from one colour to another. Dyeing of cotton and silk with henna, indigo, marigold etc., is reported. (Gulrajani et al). There is a growing interest in the revival of natural dyes in textile coloration (Mehanta Z, et al). In contrast, natural dyes are environmental friendly, exhibit better biodegradability and generally have a higher compatibility with the environment than synthetic dyes. (Ahlstrom et al). The process is economically feasible since the raw materials are readily available at a low cost, resulting in a significantly low production cost as well [1-3].

Materials and Methods

The dye was extracted from the fresh plant parts of Ixora coccinea flower (pink), Nerium oleander flower (red), Tradescantia pallida flower, Portulaca oleracea, Cissus quadrangularis stem and Celosia cristata stem, which were collected from the nearby villages of Vellore district, Vellore in the month of December, 2023 [4-6].

Materials required

•Plant materials

•Cotton cloths

•Scissor

•Beakers

•Bowls

•Glass rods

•Test tubes

•Test tube stand

•Funnel

•Filter paper

•Tripod stand

•Conical flask

•Mordants

•Knife

•Filter paper

•Mesh

Plants used

•Ixora coccinea flower (pink)

•Nerium oleander flower (red)

•Tradescantia pallida (flower)

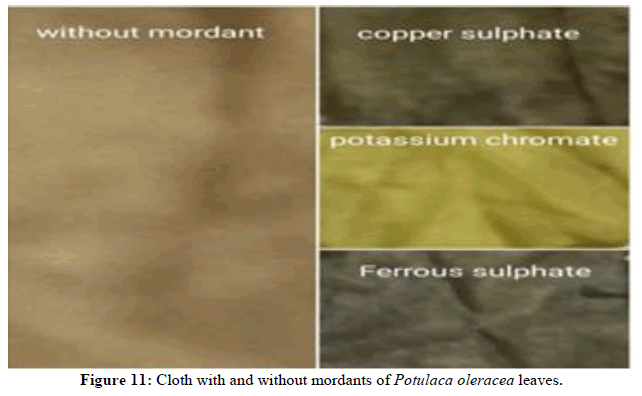

•Portulaca oleracea (flower and leaves)

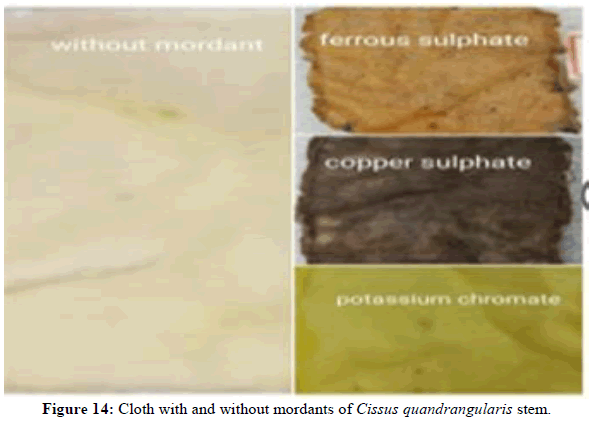

•Cissus quadrangularis stem and

•Celosia cristata stem

Extraction of dyes from the plants

The flowers of various plant materials were collected from the locality. The plant material was weighted using chemical balance (10 gram). It was thoroughly washed with distilled water and allowed to dry. The chopped flower material was dissolved in 100 ml of distilled water in beaker and was heated for 30 minutes at a temperature range of 80°C-85°C, until the dye was released. The dye from aqueous extraction was filtered through a funnel and filter paper. After the dye was extracted, it was stored in a closed flask, in the refrigerator for further use [7-9].

Preparation of mordant

Mordant: The creation of a bond between the coloring matter and fiber is called mordanting.

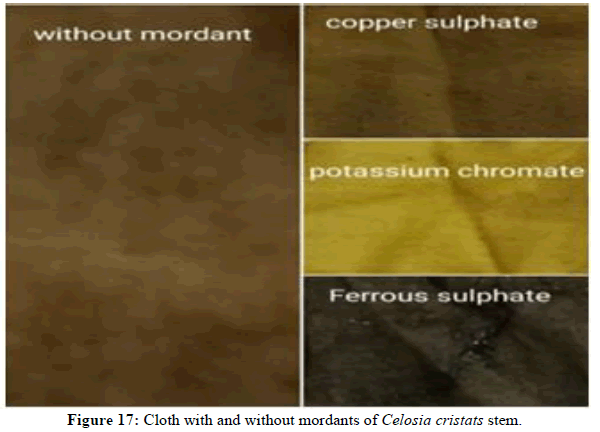

Copper sulphate: 5 g of copper sulphate was dissolved in 100 ml of distilled water.

Ferrous sulphate: 5 g of ferrous sulphate was dissolved in 100 ml of distilled water.

Potassium chromate: 5 g of potassium chromate was dissolved in 100 ml of distilled water.

Preparation of the cloth: The cloth material (cotton) is cut into small pieces (10*10 cm) and it is dissolved in sodium hydroxide and refluxed for 15 minutes to remove the starch; cellulose and other dirt particles from it.

The cloth treated with sodium hydroxide was put in the mordant solution and simmered for 15 minutes and then it is taken out.

Application of dye to fabrics: The dye is applied to fabric by two methods:

•Without mordant

•With mordant

Without mordant: The fabric which is treated with sodium hydroxide is directly immersed at the dye bath and the fabric is simmered for half an hour. After the dye enters through the cloth. The cloth is taken out and dried for further studies.

With mordant: The mordant fabric is immersed in dye bath for half an hour. After that the dye enters through the cloth. The cloth is taken out and dried.

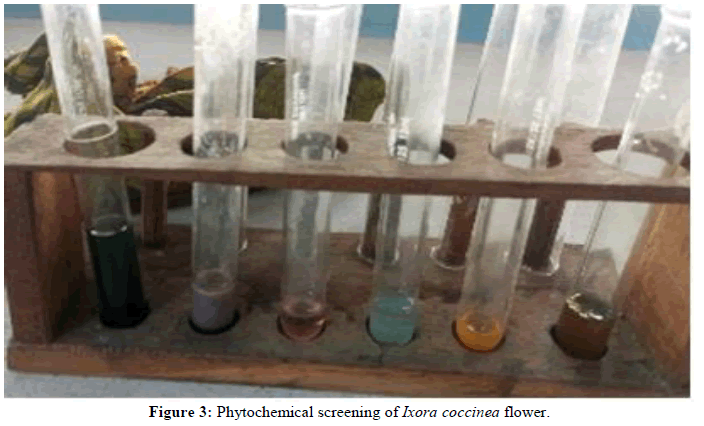

Phytochemical test

Detection of phenols

Ferric chloride test: To 3 ml of the extracts 3-4 drops of ferric chloride solution was added. Formation of bluish black color, indicates the presence of phenols.

Detection of tannins

Gelatine test: To 3 ml of the extracts 1% gelatine solution containing sodium chloride was added. Formation of white precipitate indicates the presence of tannins.

Detection of flavonoids

Alkaline reagent: To 3 ml of the extracts sodium hydroxide solution was added. Formation of intense yellow color, which becomes colorless on the addition of dilute acids, indicates the presence of flavonoid.

Lead acetate test: To 3 ml of the few drops of lead acetate solution was added. Formation of yellow precipitate indicates the presence of flavonoid.

Detection of saponins

Foam test: 1 ml of the extracts was diluted with distilled water to 20 ml and shaken in a graduated cylinder for 15 minutes. Development of stable foam indicates the presence of saponins.

Froth test: 1 ml of the extracts taken in various test-tubes was stoppered and shaken vigorously for about 5 min, it was allowed to stand for 30 min and observed for honeycomb froth, which was indicative of the presence of saponins.

Lead acetate test: To 1 ml of the extracts, 1% lead acetate solution was added. Formation of white precipitates indicates the presence of saponins.

Detection of steroids A few drops of acetic anhydride are added to the extracts and the formation of violet to blue to green in some samples indicates the presence of

steroids.

Quinine 1 ml of the extracts was mixed with few drops of concentrated hydrochloric acid; appearance of green color indicates the presence of quinine.

Cellulose 1ml of the extracts was mixed with iodine crystals and then a few drops of conc. sulphuric acid is added. Appearance of brown color indicates the presence of cellulose.

Detection of terpenoids

Salkowski’s test: Extract of 5 mg of the selected plant part is mixed with 2 mL chloroform and 3 mL concentrated sulfuric acid added carefully to form a layer. A reddish-brown color indicates the presence of terpenoids.

Detection of glycosides The leaf extracts were individually hydrolyzed with dilute HCl and filtered.

Legal’s test: To 3 ml of the extracts sodium nitroprusside in pyridine and sodium hydroxide was added. Formation of red color, indicates the presence of glycosides.

Borntrager's test: To 3 mL of the extracts, 5 ml dilute HCl and 5 ml FeCl3 was added. The mixture was cooled and extracted with equal volumes

of benzene. The benzene layer was separated and treated with ammonia solution. Formation of red/pink colour, indicates the presence of glycosides.

Fat and fixed oil 1 ml of the extracts was mixed with Sudan III which results in shining orange which indicates the presence of fat and fixed oil.

| E1 | E2 | E3 | E4 | E5 | E6 | |

|---|---|---|---|---|---|---|

| Phenol | + | + | + | + | + | + |

| Tannin | + | + | - | + | + | + |

| Flavonoids | + | + | + | + | + | + |

| Saponin | + | - | + | + | + | + |

| Steroids | + | + | - | + | - | + |

| Quinine | - | - | - | - | - | - |

| Cellulose | + | + | - | + | + | + |

| Terpenoids | + | + | - | + | + | + |

| Glycosides | + | - | - | + | + | - |

| Fat and fixed oil | - | - | - | + | - | - |

Note: +: Present; -: Absent

Table 1: Phytochemical test.

Results and Discussion

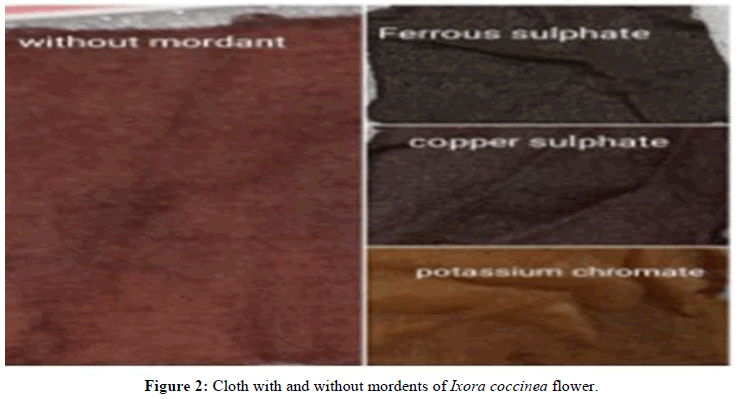

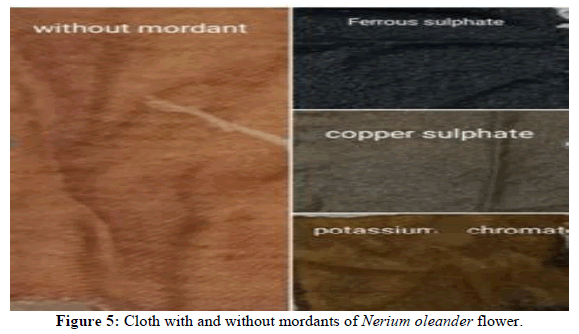

The color of the dye extracted from the plant is determined by the compounds present in that particular plant. The colorant is subsequently applied to the cotton fabric to ensure color permanence. The fabric showcased above has successfully bonded with the appropriate dye through the assistance of a mordant. By incorporating these mordents into the dye, various hues of color were achieved, allowing us to create diverse shades from a single plant with the aid of the mordant. Preliminary phytochemical screening of the all the extracts showed the presence of phenols, tannins, flavonoids, saponins and glycosides. This screening test on the extracts showed the absence of quinines, fat and fixed oils in maximum number of plant parts (Figures 1-18) [10-12].

Conclusion

The utilization of plants for dyes is considered crucial. Lately, there has been a significant increase in interest towards natural dyes, mainly due to the strict environmental regulations imposed by numerous countries in response to the harmful effects and allergic reactions caused by synthetic dyes. As a result, with a distinct lowering in synthetic dyestuff costs, the natural dyes were virtually unused at the beginning of twentieth century. Currently, in the majority of nations, natural dyeing is predominantly carried out as a traditional craft, while synthetic dyes have become the norm in all industrial dyeing procedures.

References

- Gupta M, Thakur S, Sharma A, et al. Orient J Chem. 2013; 29(2): p. 475-481. [Crossref]

- Ahlström LH, Eskilsson CS, Bjorklund E. TrAC Trends Anal Chem. 2005; 24(1): p. 49-56.

- Baliarsingh S, Panda AK, Jena J, et al. J Clean Prod. 2012; 37: p. 257-264.

- Kumaresan M, Palanisamy PN, Kumar PE. J Appl Sci Res. 2011; 1(8): p. 933-441.

- Deshkar N, Tilloo S, Pande V. Pharmacog Rev. 2008; 2(3): p. 124.

- Amari NO, Bouzouina M, Berkani A, et al. Asian Pac J Trop Dis. 2014; 4(2): p. 104-109.

- Guinot P, Gargadennec A, Valette G, et al. Phytochem Anal. 2008; 19(1): p. 46-51.

[Crossref] [Google Scholar] [PubMed]

- Khan MI, Ahmad A, Khan SA, et al F. J Clean Prod. 2011; 12(19): p. 1385-1394.

- Bhuyan R, Saikia CN. Bioresour Technol. 2005; 96(3): p. 363-72.

[Crossref] [Google Scholar] [PubMed]

- Kadolph S. J Delta Kappa Gamma Bulletin. 2008; 75(1): p. 89-94.

- Gavamukulya Y, Abou-Elella F, Wamunyokoli F, et al. Asian Pac J Trop Med. 2014; 7: p. 355-363.

[Crossref] [Google Scholar] [PubMed]

- Cardozo ML, Ordonez RM, Zampini IC, et al. Int Food Res. 2010; 43(5): p. 1505-1510.