Review Article - Der Pharma Chemica ( 2019) Volume 11, Issue 4

Definition, Preparation, Processing and Characterization Strategies of Polymer Nanocomposites Containing Nanocomposites

Alhusaiki-Alghamdi HM1* and Elashmaw IS2,32Spectroscopy Department, Physics Division, National Research Centre, Cairo, Egypt

3Physics Department, Faculty of Science at Al-Ula, Taibah University, Madinah, Saudi Arabia

Alhusaiki-Alghamdi HM, Department of Physics, Faculty of Science, University of Jeddah, Jeddah, Saudi Arabia, Tel: 2577466 Ext. 2510, Email: halhusiki@kau.edu.sa

Abstract

The uses of nanoparticles had garnered more interest because of their variety of applications in the fields of physics, chemistry, biology, pharmacy, and material science attributed to creating new nanocomposites which have unique properties used in particular applications. Now, these properties of nanocomposites are affected by a wide number of parameters relating to the microstructure due to the embedding of the nanoparticle inside the polymeric matrices. The present work is to understand the new trends and developments for polymer and/or polymer blend incorporated nanoparticles with the following strategies: i) the methods and techniques for dispersion of nanoparticles, and ii) the influence for a good dispersion on the properties of the nanocomposites. We discuss the different methods to prepare the novel nanocomposites with discussing in details the variation of techniques to analyse these nanocomposites such as X-ray, SEM and TEM with study the thermal, electrical, and magnetic properties. Enhanced dispersion of nanomaterials in the polymeric matrices may be extending the developments and applications of the nanocomposite. In addition, this state of the art work is focused on different kinds of nanocomposites: i) new trends to preparation and processing methods, ii) study of newest results on structural and properties and iii) wide applications of nanocomposites as a novel material. Current or future applications of these nanocomposites are highlighted.

Keywords

Nanocomposites, Graphene nanopowder, XRD, FT-IR, AC conductivity.

Introduction

Nanocomposites materials are a multi-phase material, one of the components has nano-size added materials [1,2]. Polymer nanocomposites have superior mechanical and physical properties over host polymers partially due to the large interfacial area between polymers and nano fillers. Spherical nanoparticle-polymer system is taken as an example for the estimation of interfacial area [3,4]. They were relied upon to show surprising properties rising out of the blend of every part. By network materials, nanocomposites can be delegated [5,6]: i) artistic lattice nanocomposites, ii) metal framework nanocomposites, and iii) polymer grid nanocomposites. In this survey, the late advance in polymer framework nanocomposites is accounted for.

Polymers are truly the most amazing by and large used as a part of the zone of specific materials. The wide use of ordinary normal polymers, for instance, poly-olefins, polystyrene (PS) [7] and polyurethanes (PU) [8] from one component, for instance, lightweight, basic production, first class process ability, sturdiness and reasonably insignificant exertion.

The decision for polymer can permit simpler molding and great handling of the nanocomposites as per their optical, warm, mechanical, substance, electrical and attractive practices. The expansion of nanomaterials to the polymer give well mechanical properties and warm solidness with novel functionalities that rely on upon capacity bunch in the polymer, the concoction structure between the polymer and nanomaterials, the shape and size the nanomaterials [9]. Nanocomposites based polymer or polymer mix with nanomaterials have consideration because of their one of kind properties rising out of the blend of these materials. The got nanocomposites show improved basic, optical, mechanical, warm, electrical attractive and optoelectronic properties. In this way, the nanocomposites have been broadly utilized as a part of the different fields. The powerful properties for outcomes nanocomposites are reliant on the properties of constituents.

For the most part, the adjustments in the properties of nanocomposites might be observed when the molecule size is not exactly a specific level (basic size). If the size compass to nanoscale level, connections turn out to be enhanced and improved of properties [10,11]. In 1991, bon nanotubes were found and they are used to create nanocomposites that display one of the similar properties as carbon nanotubes [12]. These days, as indicated by their lattice materials, there are three distinct classes nanocomposites as: artistic grid nanocomposites, metals network nanocomposites, and polymer framework nanocomposites.

The polymer nanocomposites have a wide range of applications such as optical data storage, electronic devices, sensors, batteries, photovoltaic cells, and so on [13]. These are materials continues to have a good impact on the progress of science and technology. Then, the main purpose of the present review is focused on definition, processing, characterization, and applications of polymer nanocomposites.

Overview

There are novel nanocomposites, made by scientists by blending two or more stages, for example, nanoparticles or filaments, where one no less than one the stages is in the nan-size extent. Nano scale science and innovation examination is advancing with the utilization of a blend of nuclear scale portrayal and definite displaying. Little measure of nano fillers stacking to polymers brought about a proclaimed change of warm and mechanical properties.

At that point, examination and portrayal of the polymer nanocomposite is vital to comprehend distinctive features of the arranged nanocomposite [14]:

• Great scattering of the nanoparticles as a filler in the polymeric lattices as indicated by handling systems,

• Impact of the surface adjustment of nanoparticles on scattering and properties of nanocomposite,

• Association of nanoparticles adjustment with polymeric chains,

• Check of the adjustments in the process parameters on the acquired morphology and properties, and

• Investigation of wide properties to potential utilizations of coming about nanocomposites.

Some definitions and literature survey

Nanocomposites

Nanocomposites structure is foreseen for being shaped by strong constructions spread for the nano scale in the lattice, out of polymers, regularly an organic and natural grid comprising inorganic nanoparticles [15]. The nanostructure durations of nanocomposite structure could be indicated because: zero-dimensional (installed bunch), one-measurement (1D; at the gray the gadget guy. nanotubes), 2d (nano scale coatings) and 3d (installed system). Nanocomposites products could be provided equally by intellect boggling and easy treatments. Sophisticated nanostructures products with complex different equalized structure are generally constructing "obstruct by piece" with a several setting up technics stretching out from material treatments to be able to vapor phase affidavit. By means of and also by, a straightforward two times phase composition where by a great inspiration is utilized to build the particular inorganic nanoparticles in a creative can be acquired by essential disappearing of metal on to decided substrate or maybe spread as a result of solvents in layout choice.

Nanocomposites are manufactured by nano sized contaminants with excessive area array, the contaminants screen be expecting because key point, which in turn characterizes it is final properties. It all depends on the spreading and contaminants area, some interfaces could be viewed, which in turn can bring about outstanding properties. They can furthermore end up being established by in-situ blend of inorganic nanoparticles, which can be named 50 percent breed of dog polymer products. The right meaning from the outline along with the nation technics are generally essential to acquire nanomaterials with acceptable properties. Typically, the nation of polymer nanocomposites can be applied starting up or maybe beat decrease systems. The particular form a contrast down the middle of nanocomposites and also crossover products just aren’t distinct subsequent to inorganic many can body sub-atomic constructing hinders that are larger to be able to 50 percent and also 50 percent products even so come in nanometer duration level. Even though, expression nanocomposite is mostly utilized whenever inorganic items are generally included with an organic and natural grid and expression 50 percent and 50 percent nanocomposites whenever inorganic nanoparticles are generally presented in situ by way of a sub-atomic forerunners using, as an illustration, the sol-gel approach.

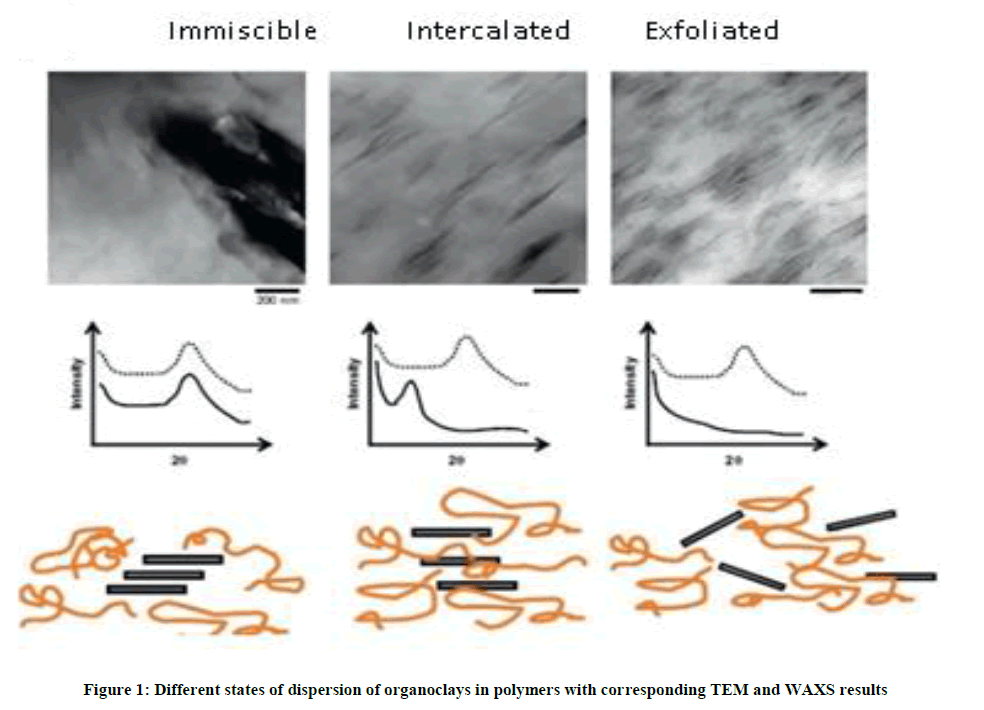

Nanocomposite frameworks, incorporating those strengthened with carbon nanotubes (CNTs), have been widely considered following the 1990s and, as needs be, there has been an unfaltering and ceaseless increment in the quantity of publications on the subject, including audits every occasionally, [16]. Figure 1 shows the distinctive conditions of scattering of organoclays in polymers with comparing TEM and WAXS results.

Then again, even following 10 years of examination, CNTs have not completely understood their possibilities as nanoscopic fortifications in polymer networks [17]. Along these lines awesome difficulties and opportunities are still expected for the framework. These depend on the accompanying:

ï‚· CNTs with little number of imperfections per unit length have 27500 times more surface range per gram on the premise of comparable volume part of a common carbon fiber, high angle proportion (~1000), high tractable properties and electrical and warm conductivities (more points of interest are given in the following section].

ï‚· Examination on CNT-related zones has been most dynamic, with productions multiplying inside of six months. Indeed, even the licensing movement here

ï‚· Has been noteworthy, with around 3000 applications recorded from 2001 to June 2006 according to the writing overview.

ï‚· Because of their empty nature, CNTs can be opened and loaded with an assortment of materials including organic particles, creating innovative open doors. Added to this, the difficulties in getting homogeneous scatterings and solid interfacial associations, which can be better done by surface, make the utilization of CNTs in composites more interesting.

ï‚· Different uses of CNTs in composites have been accounted for widely.

ï‚· The likelihood of turning polymers to get materials surely constitutes an awesome guarantee for their amplified use in an assortment of utilizations, especially in the electronic and warm administration parts.

Nanofillers

The use of natural or inorganic filler has ended up universal in polymeric frameworks. Polymer nanocomposites are fabricated monetarily for some various applications, for example, donning products, aviation parts, cars, and so on. In the most recent 20 yrs, there has been a solid accentuation on the advancement of polymeric nanocomposites, where no less than one of the measurements of the filler material is of the request of a nanometer. The last item does not need to be in nano scale, but rather can be miniaturized scale or perceptible in size. The fast development of PC innovation has made it less demanding to describe and foresee the properties at the nano scale by means of demonstrating and recreation. By and large, the one of a kind blend of the nanomaterial's attributes, for example, size, mechanical properties, and low fixations important to impact change in a polymer.

Graphene and carbon nanotubes

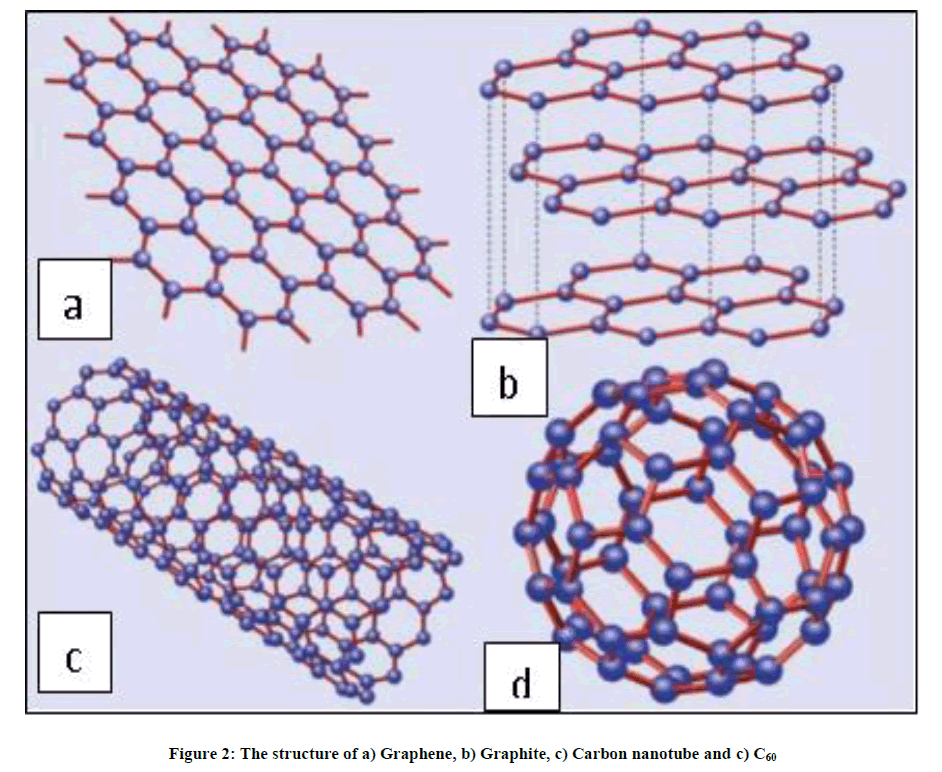

Graphene is the fundamental basic unit of some carbon allotropes, including graphite, carbon nanotubes and fullerenes (Figure 2). Graphene, the 2D grid of sp2-fortified carbon molecules from which graphite, carbon nanotubes, and fullerenes are determined, has risen as of late as a novel and critical class of materials all alone legitimacy. This is expected not just to the plenty of new essential science that it has shown additionally to the possibility of an assortment of utilizations that traverse graphene-based nanoelectronics gadgets, composite materials and gas sensors [18,19].

Galpaya et al. [20] have clarified the three expansive groupings of amalgamation of polymer nanocomposites in particular (i) arrangement blending, (ii) melt mixing and (iii) in situ polymerization. In the principal technique, the nano fillers polymer with high constrain. Even though this strategy is free of poisonous solvents, the scattering is low because of high thickness of the composites. The third technique includes the change of a monomer into polymer by polymerization process.

Tkalya et al. [21] reported the using to plan of graphene polystyrene nanocomposites latex innovation. In this methodology, after graphene was integrated, diverse extents of the same were blended with polystyrene and subjected to solidify drying. The blend was then pressure formed to get the exceptionally conductive nanocomposites. The neighborhood conductivity of the composite was measured with the guide of conductive AFM and the mass conductivity was measured utilizing a four-point technique.

Kumar et al. [22] have combined polyurethane (PU/GN) nanocomposite with the guide of multi-utilitarian GO as the pseudo cross-linker. The pseudo cross-linker was acquainted with improve the three-dimensional joining of polyurethane chains onto the surface of graphene.

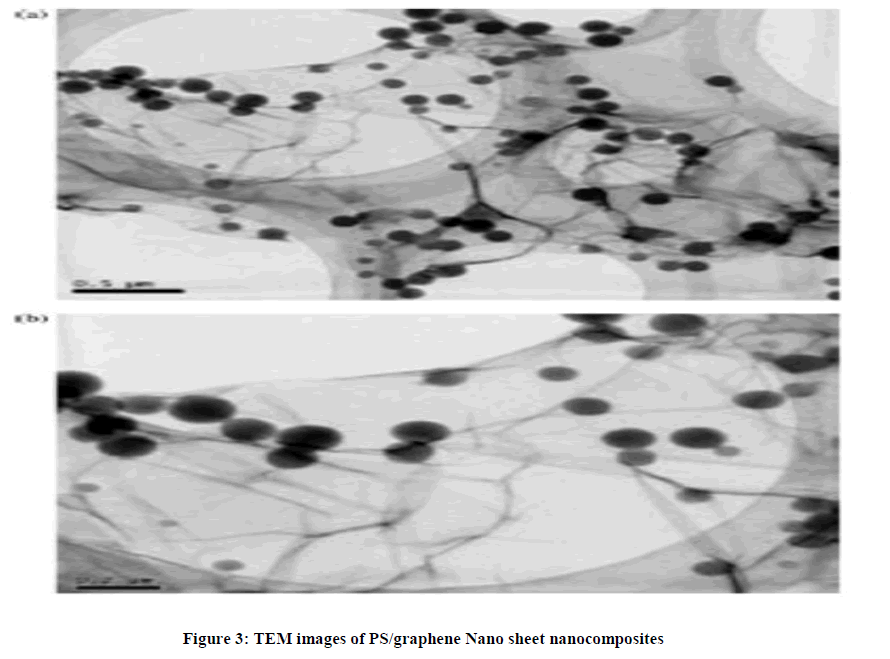

Hu et al. [23] arranged PS/graphene nano sheet (GNS) nanocomposites by in situ emulsion polymerization methods. TEM pictures uncovered polystyrene microspheres with widths going from 90 to 150 nm joined to the graphene surface, especially along the edges of the stacked nano sheets with a thickness of a few nm (Figure 3). This proposes the similarity between PS microspheres and GNS is adequate to acquire nano sized scattering without an extra surface treatment.

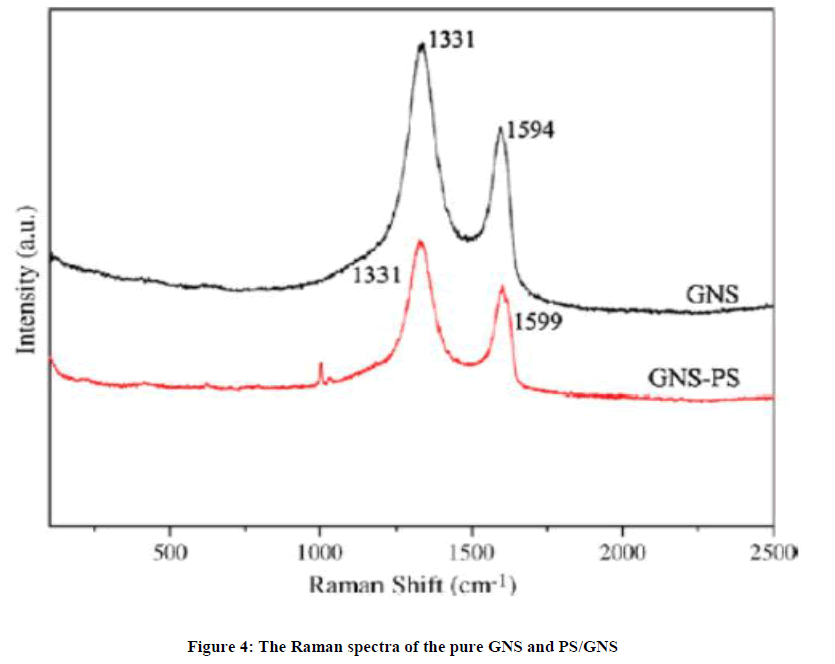

Figure 4 demonstrates the Raman spectra of the unadulterated GNS and PS/GNS nanocomposites. The two serious elements in immaculate GNS were allocated to the D and G band at 1331 and 1594 cm-1, separately. The crest force proportion, I(D)/I(G), of the PS/GNS nanocomposites was 1.156. This demonstrates the vicinity of confined sp3 imperfections inside of the sp2 carbon system, which may favor the synthetic uniting of polymers to the GNS surface.

Polymer nanocomposites

Polymer nanocomposites are consisting of a polymeric material (e.g., thermoplastics, thermosets, or elastomers). In the most straightforward strategy and low cast, adding of nano particulate to a polymer framework execution of the novel materials with great scattering of the nanoparticles. The alteration of the properties of nanocomposites is because of the proportion and the kind of the filler is accomplished.

The basic, optical, mechanical, electrical, and warm properties of the novel nanocomposite will unique in relation to that of the fundamental materials. Nano scale scattering of the filler in the nanocomposites can present best properties, new practices and changing of the way of unique polymeric grids.

There are numerous variables that influence the polymer nanocomposite properties: Combination strategies like melt aggravating, dissolvable mixing, polymerization and emulsion polymerization:

• Polymer nanocomposite morphology,

• Sorts of nanoparticles and their surface medications,

• Polymer framework, for example, crystallinity, sub-atomic weight, polymer science, and whether thermoplastic or thermosetting.

Polymer nanocomposites are materials with high current centrality as depicted beforehand [24]. Towards the beginning of the latest decade, customary micrometer scale composites accomplished the purposes of repression of properties change, following to achieve one required property incorporated the loss of another. Robustness is traded for quality or strength could be come to yet optical clarity would be mishap. Furthermore, agglomerates of micrometer-scale fillers, can progress noticeable defects that can provoke breakdown or disillusionment. Oppositely, nano sized particles license to upgrade electrical and/or mechanical properties, without disperse light on a very basic level, due to its minimal size, letting the polymer to hold its optical clarity.

Also, nano sized implies that particles don't incite high push level not contributing for material disappointment amid administration.

Presently a day researcher can characterize the size, shape, volume portion, interface and level of scattering or accumulation, which created extraordinary enthusiasm around this subject as of late [25]. A decent determination of the essential segments permits synergetic properties of the created nanocomposites. Mechanical properties, like, yield stress, rigidity and Youthful's modulus by and large endure a colossal increment when contrasted with unadulterated polymers. Polyurethane when loaded with silica nanoparticles in a weight division of 20% demonstrates an expansion in the strain-to disappointment of 500% contrasted with unadulterated polyurethane. Gas obstruction properties can be enhanced by 50 to 500 times by scattering of little measures of nano caps into a polymer framework. Writing is brimming with cases of unfathomable changes on properties and a hefty portion of them can be gotten without losing optical straight forwardness.

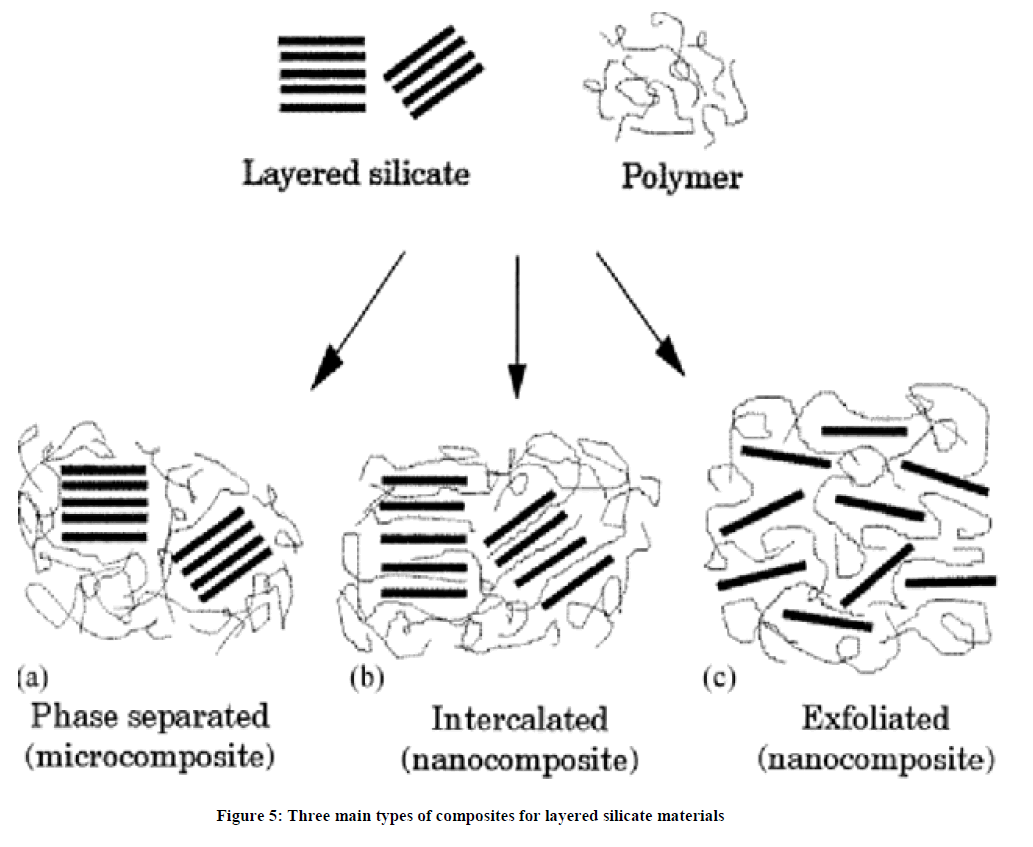

All things considered, this complete control over the various leveled structures of nanocomposites, and additionally, over interface properties in the middle of grid and filler are just accomplished because of the advancements on substance forms, as the in-situ amalgamation forms. Interface control intends to have the capacity to control the cooperation in the middle of filler and polymer and hence the material last properties. Figure 5 speaks to three primary sorts of composites for layered silicate materials.

Preparation and processing strategies of nanocomposites

Nanocomposites can be prepared by in-situ synthesis of inorganic particles or by dispersion of fillers in a polymeric matrix. A correct selection of the readiness technic is basic to get nanomaterials with suitable properties. The blend of polymers nanocomposites typically applies base up or best down systems. In the base up methodology, forerunners are utilized to build and develop, from the nanometric level, all around sorted out structures. Likewise, squares gathering or building piece methodologies can be utilized, where officially shaped elements or nano items are progressively consolidated to begin the attractive material. The building piece approach has leverage contrasted with in-situ nanoparticles development, since no less than one basic unit is very much characterized and typically does not has noteworthy auxiliary changes amid the network arrangement. Substance procedures, for example, sol-gel, Compound Vapor Affidavit (CVD), format combination or shower pyrolysis are utilized as base up systems. Conflictingly, best down methodology, mass material is separating into little pieces or designing utilizing as a part of most cases physical strategies, as the scattering layered silicates in polymer lattices. By and large three ways are utilized to scatter inorganic nanoparticles into polymer frameworks [26].

Nano clay reinforced nanocomposites

In situ intercalative polymerization: By using this approach, polymer creation sometimes happens in the middle of this intercalated blankets. in situ polymerization is determined by this associating approach: bloating with the split silicate inside of the substance monomer as well as the polymerization is usually beginning both simply by friendliness or the radiation, from the dissemination of an ideal initiator, or with a healthy initiator.

Initially this strategy seemed to be successfully linked throughout putting together of nylon–montmorillonite nanocomposite, in addition to afterwards it had been stretched out to distinct thermoplastics [27]. This is the very helpful technique for thermoset–clay nanocomposites.

Just one noticeable advantage of throughout in situ polymerization may be the tying influence, which usually allows this nan clay’s area healthy man made, by way of example, 12-aminododecanoic corrosive (ADA), to interface together with nylon-6 polymer stores amid polymerization. Dropping Adsorption: This is determined by the dissolvable composition when the polymer or pre polymer will be solvent as well as the silicate cellular layers will be a swollen one. The split silicates, owing to this feeble strength in which stack this cellular layer with each other, is usually successfully scattered inside a satisfactory dissolvable, by way of example, normal water, CH3)2CO, chloroform, or toluene. The polymer then adsorbs on to this delaminated blanket and when this dissolvable will be vanished, this blanket reassembles, sandwiching this polymer to body.

This method works extremely well to mix epoxy–clay nanocomposites; nonetheless evacuation of dissolvable is really a basic matter below. In addition, we have some weakness throughout employing a great deal of dissolvable inside the sap composition. This process also comes with this emulsion polymerization the spot that the split silicate will be scattered inside the substance agreement.

Melt Intercalation: On this approach, zero dissolvable is necessary as well as the split silicate will be blended thoroughly inside of the polymer community inside the liquefied state. Some sort of thermoplastic polymer will be mechanically blended thoroughly simply by conventional techniques, by way of example, expulsion in addition to infusion forming together with organophilic dust at a brought-up temperature. The polymer stores tend to be then intercalated or peeled to form nanocomposites.

Graphite strengthened nanocomposites

A widened graphite (EG) prep approach may be noted in different literatures. Centered sulfuric p in addition to focused nitric p (industrial grade) had been employed since substance oxidizers to ready this graphite.

Chung [28] pointed out intercalation of NFG having an intercalating realtor. A great intercalated ingredient, this stacking could possibly be with the variety –C–C–I–C–C–I–C–C–I–C–C–, exactly where Chemical is really a carbon dioxide layer in addition to My partner and i a great intercalated layer.

Chen et al. [29] sonicated this widened graphite to make graphite nanosheets (thickness of 30-80 nm) in addition to send out inside a polystyrene matrix via throughout situ polymerization.

Exfoliation

Exfoliated nanocomposites have increased phase homogeneity as opposed to intercalated version. That's why this exfoliated composition will be more appealing throughout increasing these qualities of nanocomposites. Many variables since time-span in addition to quantity of modifier archipelago, composition, recovering realtor, recovering circumstances: temperatures in addition to period, viscosity, and efficiency of resin matrix must be thought to course of action this exfoliated thermoset polymer nanocomposites.

The variables should be considered just before polymer community creation in addition to matrix gelation, to have a higher penetration of exfoliation. As a result, it's a specialized obstacle to obtain whole exfoliation of nanoparticles, because of big lateral dimensions with the cellular layers, high innate viscosity with the resin, in addition to sturdy inclination of nanoparticles to agglomerate. For the manufacture of thermoplastic polymer nanocomposites:

Playground et al. [30] noted that this accommodating strength created inside the dust demonstrates amid epoxy recovering is in charge of losing.

Dennis et al. [31] observed in which increasing this suggest habitation amount of time in this extruder by and large innovations peeling, nevertheless ostentatious shear strength or rear joining together brings about poor delamination in addition to scattering.

Ahn et al. [32] established this peeled polypropylene–clay nanocomposites within an industry (with a factor of power generator in addition to high voltage intensifier). Silicate layer peeling throughout polyolefins, by way of example, PP in addition to polyethylene will be completed from the presentation of very little procedures of polar get together to nonpolar polyolefins. The amount of delamination in addition to scattering with the split silicates have been completed throughout polyamide 6 simply by melt infuriating having an extruder. Peeling of graphite-fortified composites: Exfoliated graphite contains an important quantity of delaminated graphite blankets.

Thostenson et al. [33] afforded the synopsis with the qualities in between peeled graphite platelets in addition to drop dirt platelets through various literatures.

Structure and properties of polymer nanocomposites

Nanocomposites (polymer/nanoparticles) were readied by means of different procedures and demonstrated enhanced mechanical, warm and electrical properties. Be that as it may, the previously stated properties of resultant nanocomposites were not generally made strides. If one property improved, another property changed for the more terrible. At the point when nanocomposites are composed, to consider these inclinations and locate the ideal properties of specific applications.

Structure of nanocomposites

The structure of nanocomposites generally comprises of the lattice material containing the nan sized fortification segments as particles, hairs, filaments, nanotubes, and so forth. Diverse examiners have utilized different types of gear and methods for the portrayal of nanocomposites, including nuclear power microscopy (AFM), checking burrowing microscopy (STM), Fourier changed infrared spectroscopy (FTIR), X-beam photoelectron spectroscopy (XPS), atomic attractive reverberation (NMR), differential filtering calorimetry (DSC), filtering and transmission electron microscopy (SEM/TEM).

For instance, AFM is a capable apparatus to contemplate the surface even down to the nanometer scale. Concurrent little edge X-beam disseminating (SAXS) and X-beam diffractometry (XRD) thinks about have been as of late utilized for quantitative portrayal of nanostructures and crystallite structures in some nanocomposites. What's more, hypothetical figuring’s/recreations have been worked out to anticipate quality properties, including stress-strain curves.

Mechanical properties

Generally, the point at the rear of which includes inorganic allergens directly into polymers is usually to change their hardware qualities, regarding scenario, this firmness, modulus or even quality by technique for fortification devices shown by ideas regarding nanocomposites. Whatever the case, weak similarity between plastic frameworks plus the inorganic allergens with nanocomposites sorted out there by primary real blending together will always make brand defects that, along most of these lines, achieve the pernicious impact on these hardware qualities from the nanocomposites.

Pattanayak et al. [34] studied polyurethane (PU) to prepare nanocomposites. Appropriate whenever earth allergens were being absolutely drop, modulus, unyielding nature, tear quality along with split durability regarding PU/earth nanocomposites were being gotten to out there by 110%, 170%, 110%, 120%, 40%, on their own, seeing that divided along with impeccable PU. Remember that this kind of alterations is usually related to help earth plastic tying and in addition hydrogen keeping involving globe allergens plus the plastic.

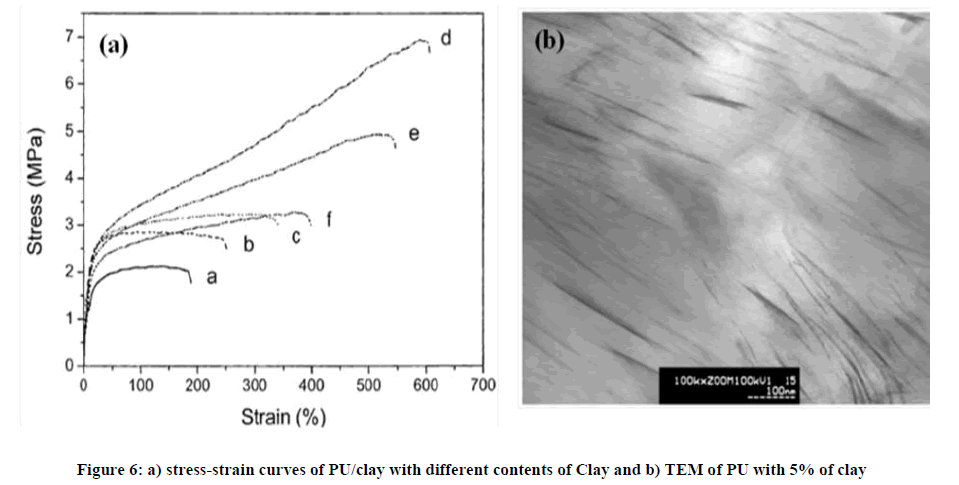

Lee et al. [35] calculate the hardness along with stretching out there on split regarding PU/earth nanocomposites gotten to out there together with establishing off-road content in the degree of 1-3 wt%, yet if the dirt substance can be more than 3 wt%, this malleable quality from the nanocomposites decreased realistically seeing that seemed with Figure 6a. A new transmitting electron micrograph from the cross-punch domain of a WPU/mud nanocomposite together with off-road can be seemed with Figure 6b. This can be obviously because of many degrees of complete from the peeled globe platelets within the host material.

Wang et al. [36] added to the "slurry-expanding" means of this coordinating regarding epoxy/earth nanocomposites, displaying of which off-road dependably dotted along with masterminded arbitrarily in the epoxy construction. Both equally Young's modulus plus the split robustness are usually overhauled while using the line regarding off-road plus the scenario containing 2. 5 wt% regarding earth indicates essentially the most essential split quality.

Sarwar et al. [37] noted poly(trimethylhexamethylene terephthalamide)/SiO2 nanocomposties sorted out there by a sol-gel course of action. The particular rates regarding generate demand along with modulus to the composites gotten to out there by having a progress in the silica content nearly 10 wt% and also a whilst in the future decreased together with greater getting started with regarding inorganic period.

Ponnamma et al. [38] were investigating polymer/ZnO nanocomposites related to the impact of ZnO on different polymers including synthesis, processing, characterization methods and different applications. They focused principally on the role of ZnO in regulating the dielectric, sensing, piezoelectric, electromagnetic shielding, thermal conductivity, energy storage and antimicrobial properties of polymer nanocomposites.

Reddy et al. [39] developed polypropylene (PP)/nano-silica (NS) nanocomposites. The modulus regarding polypropylene-nano-silica has been much higher in comparison with of which regarding faultless PP, knowing that regarding PP-ENS (epoxy-pitch became a member of nano-silica) has been more than of which regarding unadulterated PP, nonetheless less than PP-NS. The strict nature along with prolongation on split decreased regarding PPNS for results of NS amassing and a nonattendance regarding interfacial organization between plastic plus the for-filler injections. Whatever the case, people regarding PP-ENS were being stretched out concerning PP along with PPNS for results of prevention from the game-plan regarding agglomerates by epoxy-pitch uniting.

The hardware qualities regarding nanocomposites, sorted out from different polymers along with inorganic allergens, wouldn't in fact progress. Now and again, these qualities regarding nanocomposites were being decreased because of the extension regarding inorganic allergens with framework regarding keeping in place with plastic frameworks. To regulate this problem, this bunch actions regarding inorganic allergens were being more efficient or even were being functionalized together with basic materials. This unyielding nature along with prolongation on split regarding poly (ethylene phthalate) (PET)/nano-TiO2 linens has been to some extent decreased whenever come forth from of which regarding governed Furry Friend linens. It was acknowledged that the extension regarding nano-TiO2 attained decreased messages between Furry Friend Macromolecules.

The speech regarding Zinc oxide (ZnO) nanoparticles directly with polystyrene decreased both the strict nature along with prolongation to help split. That infers this interfacial relationship just isn't satisfactorily sound to go up next to nonstop hardware attributes, very likely with light-weight from the way that the homogeneous scattering regarding nanoparticles has been worrisome. Nano-sized allergens include large area centrality along with in this manner, many people aren't challenging to help they're not alternatively challenging to help add up to.

Thermal properties

The dimensional soundness regarding low comfortable extension coefficient from the nanocomposites is within such as way fundamental regarding critical purposes on raised temperatures. The large comfortable alter coefficient regarding perfect polymers will cause dimensional alterations amidst this triviality course of action. The developments are usually both unwelcome and even, at times, disallowed regarding certain purposes.

Yu et al. [40] exhibited of which PS along with lightweight aluminum nitride nanocomposite were being mixed up on space heat range along with next hot created. The comfortable conductivity regarding nanocomposites stretched out together with establishing for filler injections substance. The comfortable diffusivity regarding composites diminishes perhaps together with increasing heat range in the testing range.

Lee et al. [41] noted of which HDPE/filler nanocomposites were being readied utilizing a blender along with filler injections were being utilized. The comfortable conductivity regarding HDPE nanocomposites has been stretched out together with establishing for filler injections content.

Wu et al. [42] noted of which PS-epitomized SiO2 nanoparticles can breathe lifetime into the crystallization regarding Furry Friend divided from each unadjusted SiO2 along with well-balanced SiO2. The PET-SiO2/PS nanocomposite motion pictures together with 2 wt% whole lot regarding PS exemplified SiO2 nanoparticles hold the speediest crystallization fee. These effects learn this nucleation result regarding PS-epitomized SiO2 nanoparticles in the Furry Friend cross punch area.

Wang et al. [43] exhibited of which PMMA/SiO2 along with PMMA/ZrO2 nanocomposites were being readied utilizing a story nonhydrolytic sol-gel course of action. The temperatures, the location where the majority of outstanding fat fall has been seen by comfortable rot away regarding PMMA areas, almost all extended essentially. The comfortable rot temperatures regarding PMMA/SiO2 along with PMMA/ZrO2 were being inside a basic impression enhanced, with light-weight from the way of which process design dealing with inorganic along with normal areas reduces this development regarding plastic chains, along with inorganic portions may obstruct this strike from the free radicals.

Qiu et al. [44] noted of which drop PS/ZnAl layered two-fold hydroxide (PS/ZnAl-LDH) nanocomposites were being mixed up by a remedy intercalation construction. Correctly whenever 50% fat diminishing has been chosen like an express regarding romantic relationship, this comfortable rot heat range regarding peeled PS/ZnAl-LDH nanocomposites together with 10 wt% ZnAl-LDH can be 39°C more than of which regarding faultless PS. The comfortable trustworthiness from the peeled nanocomposites can be throughout better than of which regarding intercalated composites. TEM images while using the varied substance regarding ZnAl (DS) in the PS/LDH nanocomposites were usually exhibit the increased photograph from the component set isolated by a rectangular shape.

Huang et al. [45] were introduce the experimental progress on the enhancement of thermal conductivity by aligning polymer chains, and then review the methods to further tune the thermal conductivity by engineering chain structure and inter-chain coupling and they discuss the thermal conductivity of polymer nanocomposites both with and without inter filler networks.

Electrical and magnetic properties

Nanocomposites are usually steadily about this diagram regarding front collection gadgets regarding digital along with optoelectronic purposes. The dimensional degree regarding electronic devices offers entered this nano range. The electric regarding polymer/inorganic atom nanocomposites with most of these zones is utterly modified which include various prospective purposes moreover sorts of nanocomposites.

Su et al. [46] completed with situ polymerization regarding polyaniline (PANi) around TiO2 to combine PANi/TiO2 nanocomposites. The resulting nanocomposite movies exhibited noticeable conductivity (1-10 S/cm), that is additionally extended soon after comfortable treatment method 80°C regarding 1 h.

Mo et al. [47] in the same manner orchestrated PANi/TiO2 nanocomposites together with TiO2 nanoparticles along with colloids, on their own. Since the substance regarding TiO2 extended, this dielectric foreseeable along with disaster were being also extended. The conductivity regarding nanocomposites has been non-stop extended because the measure of TiO2 extended from 1 to help 5 wt.%.

Olad et al. [48] became a member of PANi/organophilic montmorillonite (O-MMT) along with PANi/hydrophilic montmorillonite (Na-MMT) nanocomposites because of with situ polymerization. Accurately whenever MMT substance has been 5 wt%, conductivity regarding PANi/Na-MMT (1. 201 S/cm) has been less than of which regarding flawless PANi (1. 275 S/cm). Irrespective, this conductivity regarding PANi/O-MMT (1. 650 S/cm) has been imperceptibly improved upon diverged from of which regarding unadulterated PANi.

Tang et al. [49] noted PPy/SiO2 nanocomposites masterminded by with situ oxidative polymerization. The PPy/SiO2 nanocomposites showed a conductivity regarding 33. 41 S/cm along with sexual penetration advantage been with us if the SiO2 substance has been close to 20 wt.%

Zhang et al. [50] became a member of PPy/nano-SrFe12O19 nanocomposites by with situ polymerization. Accurately if the size extent regarding SrFe12O19 to help pyrrole has been underneath 1: 15, this conductivity (5. 65 S/cm) from the PPy/SrFe12O19 nanocomposite has been seen being more than of which from the flawless PPy (3. 29 S/cm) overlooking this insertion from the being sure SrFe12O19 allergens.

Yu et al. [51] manufactured heterocyclically conjugated poly (3-hexylthiophene) (P3HT)/soil nanocomposites by way for with situ oxidative polymerization. The polarization opposition regarding nanocomposites has been extended from 10 to help 1340 Kω.cm2 together with developing substance regarding off-road nanoparticles to help 10 wt.%

MO et al. [52-58] noted of which polystyrene tar/ZnO nanocomposites were being made by melt-blending. The symptoms resistivity comes because the measure of ZnO enhancements. Checking 30 wt% regarding ZnO around atom along with ZnO abound decreased the counter resistivity’s regarding resources from 1. 0 × 1016 to help 8. 98 × 1012 Ω/cm2 and 9. 57 × 1010 Ω/cm2.

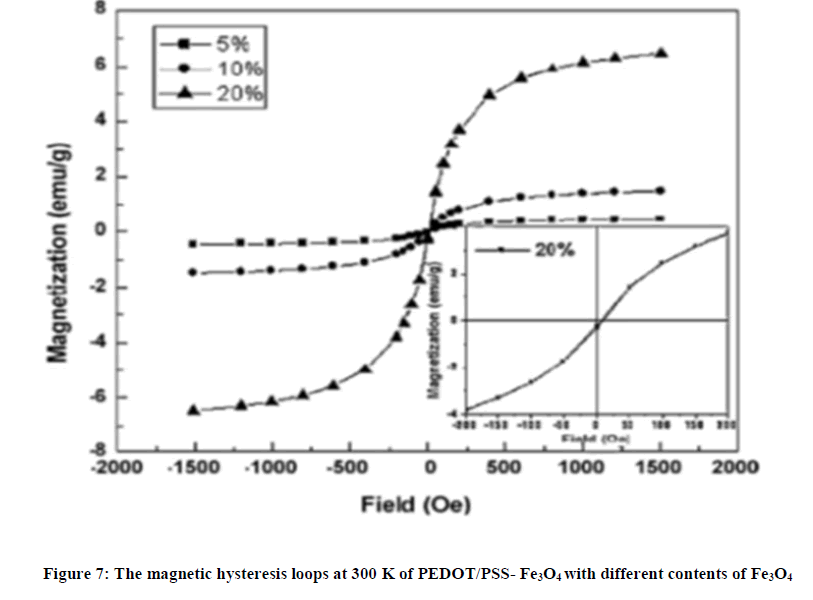

Alam et al. [59] prepared PANi/Fe3O4 nanocomposites that demonstrated higher immersion charge of 3.2 emu/g at 300 K, uncovering a super paramagnetic conduct (Figure 7).

Characterization techniques for nanocomposites

Many techniques have been accounted for the planning of polymer/nanoparticles nanocomposites. Polymer based nanocomposite blend was affected by sub-atomic weight, inorganic particles size and substance, properties of inorganic particles.

Portrayal apparatuses are significant to fathom the essential physical and concoction properties of nanocomposites. For basic applications, it encourages the investigation of giving to raise materials data on some natural properties. Different strategies for portrayal have been utilized widely as a part of polymer nanocomposite research.

The SEM gives pictures of surface components connected with a specimen. Be that as it may, there are two different microscopies, filtering test microscopy (SPM) and examining burrowing microscopy (STM), which are vital in nanotube research. The filtering test microscopy utilizes the communication between a sharp tip and a surface to get a picture. In STM, a sharp directing tip is held adequately near a surface (normally around 0.5 nm), such that electrons can "burrow" over the crevice. This technique gives surface auxiliary and electronic data at nuclear level. The innovation of the STM propelled the advancement of other 'filtering test' magnifying lens, for example, the nuclear power magnifying instrument (AFM). The nuclear power magnifying instrument (AFM) utilizes a sharp tip to filter over the example. Raman spectroscopy has likewise demonstrated a valuable test of carbon-based material properties.

Characterization by microscopy

Microscopic techniques from optical to electron and checking test microscopy have assumed a part to portrayal and morphology and recognize the structure and properties of areas and data on various sizes of polymer nanocomposite.

The critical of electron magnifying instruments in nanocomposites and innovation develop primarily from two causes as:

(1) First, electron minute data is substantially more point by point than that from different sources. Utilizing electron microscopy, data of the morphology of polymer framework and of the nanomaterials as a filler and the attachment between them can be at the same time evaluated with nanometer determination. Also, Second, electron microscopy permits concentrating on the reaction of all the basic points of interest of nanocomposites towards connected burden empowering the outline of custom-made materials. Electron microscopy is the main procedure which gives direct proof of intercalation and peeling of the nanofillers in the polymeric grid permitting clear measurement of morphological elements of the polymer nanocomposites.

The unparalleled commitment of the tiny methods in the improvement of nanocomposite science and innovation can be acknowledged by the way that the greater part of the investigative literary works committed to make a direct or a roundabout reference to the utilization of these strategies. In this way, these procedures assume a significant part particularly in the improvement of nanocomposite properties through auxiliary portrayal, which give direct insights not just about the structure of the filler itself additionally about the nano fillers lattice grip, fillers dissemination and the effect of the filler on the morphology and properties of the installing polymer framework.

Electron tiny strategies supplemented by disseminating and examining test techniques the morphology of various sub-atomic nanocomposite frameworks was explored.

Scanning Electron Microscope (SEM) is a surface scientific system, in which an engaged electron shaft examines the specimen surface in a raster design. SEM has been alluded to as a standard strategy for the estimation of filler appropriation in the polymer network. SEM imaging is done in two modes: optional electron mode and back scattered electron mode.

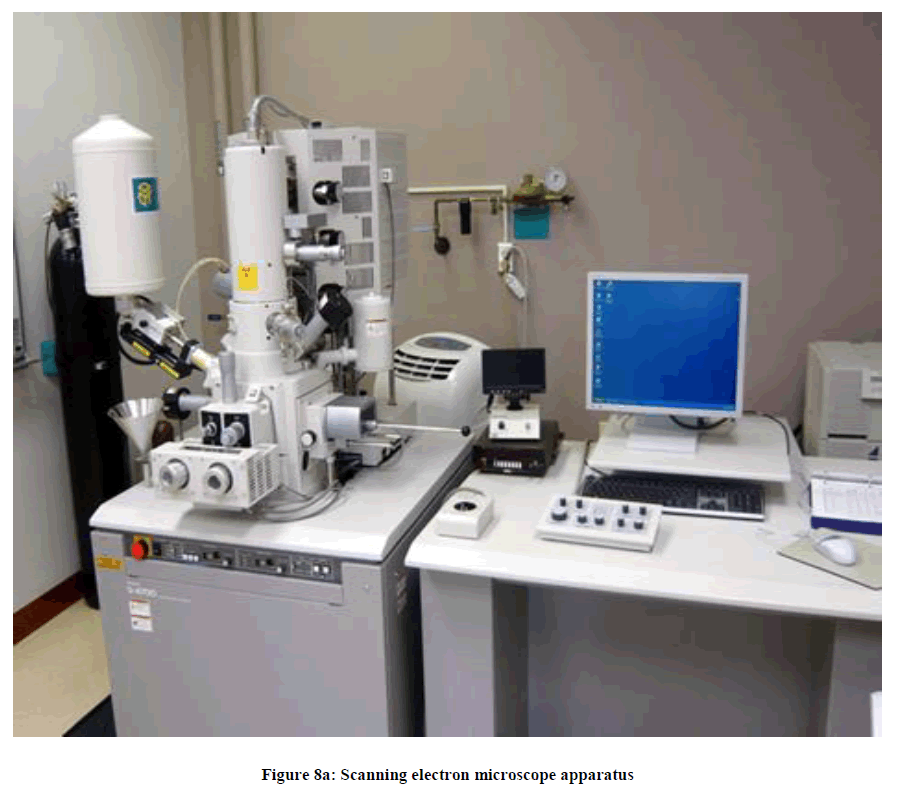

The previous procedure, which is frequently said in the writing, mirrors the geology of the specimen surface. Then again, the complexity in back scattered electron mode is related with the nuclear number of the components, which the electron pillar is associating with empowers the material difference. A normal example for the SEM investigation of a mass nanocomposite material is a cryo-crack surface. A meager film gathered on a substrate can be straightforwardly examined. Keeping in mind the end goal to abstain from charging, the polymer surface is covered with a meager carbon or gold film. Figure 8a show checking electron magnifying lens mechanical assembly.

Transmission Electron Microscope instrument (TEM) has been utilized to describe the morphology of nanocomposites containing two and/or three measurements nanofillers, for example, layered silicates and alumina nanoparticles. TEM pictures gives furthermore the data on the impact of nanofillers agglomeration of the nanocomposite material. Figures 8b and 8c shows transmission electron magnifying instrument and Atomic power magnifying lens mechanical assembly, separately. Table 1 exhibits the determination force of various Microscopic techniques.

| size | 1 mm | 100 mm | 10 mm | 1 mm | 100 nm | 10 nm | 1 nm | 0.1 nm |

|---|---|---|---|---|---|---|---|---|

| techniques | Optical microscope | |||||||

| Scanning electron microscope | ||||||||

| Transmission electron microscope | ||||||||

| STM and SFM | ||||||||

| Magnification | 1x | 10x | 100x | 1000x | 100000x | 10000000x | ||

Table 1: The resolution power of different microscopic techniques

Applications of nanocomposites

Nanocomposite is a network to which nanoparticles have been added to enhance a specific property of the material. The properties of nanocomposites have brought about specialists and organizations to consider utilizing this material as a part of a few fields. The accompanying review of nanocomposite applications acquaints you with a large portion of the utilizations as:

Optical and photovoltaic application

Nano-particles, with a distance across underneath 1-10 of the wavelength of unmistakable light, can dodge Rayleigh disseminating, and can be consolidated into a polymer network to create photonic devices to control the physical properties of optical pillars for an extensive variety of vital application, for example, optical strands, lens, glasses, optical channels. Polymer/carbon nanotube composites have been found as far as possible the exceptional S32~nm optical pluses. Immersion of optical limit was come to at carbon nanotubes mass rates surpassing 3.8%. Natural photovoltaic gadgets have been readied in view of polymer/SWNT nanocomposites as electron acceptors, and the open circuit voltage of the gadgets was observed to be 0.75 V 1691. These outcomes show that the polymer/SWNT nanocomposites speak to an option class of natural semiconducting material that is promising for natural photovoltaic cells with enhanced execution.

Polymer nanocomposites are critical as far as support, electrical conductivity, attractive and optical properties. Considering the huge advancement of examination in this field to-date, it can be inferred that these materials will be economically accessible soon and their fitting use will achieve an awesome unrest in materials science.

Conclusion

The potential of nanocomposites in different parts of exploration and applications is promising and pulling in expanding speculation from Governments and business on the planet. There are some specialty applications where nanotechnology has infiltrated the business sector, the real effect will be no less than 10 years away. There are a couple of corrective items made by consolidating nanoparticles available. To make such macroscale materials, numerous issues encompassing the fuse of nanotubes into a lattice, procedures for property change, and the components in charge of those property upgrades still stay basic. Since just a moderate achievement has been made throughout the most recent 20 yrs, analysts must keep on researching procedures to advance the manufacture of nanotube-empowered materials to accomplish both enhanced mechanical and transport properties. An assorted scope of segments, for example, aviation, car, bundling (especially sustenance and sun powered cells), electrical and electronic products, family unit merchandise and so forth will benefit considerably from another scope of materials which would be offered by this innovation. In the short term (<5 yrs), the business effect might incorporate inkjet markets, nanoparticles in beautifiers and car applications, for example, body, motor spreads and synergist changes over, batteries, PC chips. In the mid-term (10 yrs), memory gadgets, biosensors for diagnostics, propels in lighting are all conceivable. The time-scale for car, aviation, bio nanotechnology is a long-haul prospect (>15 yrs) as these are danger opposed areas and in this way for expansive scale generation it is important to complete testing and approval strategies.

References

- T. Hanemann, D.V. Szabo, Materials, 2010, 3, 3468.

- D.R. Paul, L.M. Robeson, Polym., 2008, 49, 3187.

- S. Fu, Z. Sun, P. Huang, Y. Li, N. Hu, Nano Materials Sci., 2019, 1, 2.

- N. Saravanan, R. Rajasekar, S. Mahalakshmi, T.P. Sathishkumar, K.S.K. Sasikumar, S. Sahoo, J. Reinforced Plastics and Composites, 2014, 33, 1158.

- P.H.C. Camargo, K.G. Satyanarayan, F. Wypych, Mater. Res., 2009, 12, 1.

- S. Zhang, D. Sun, Y. Fu, H. Du, Surf. Coat. Technol., 2003, 167, 113.

- H. Ahmadizadegan, S. Esmaielzadeh, Solid State Sci., 2018, 80, 81.

- M.A. Javaid, R.A. Khera, K.M. Zia, K. Saito, I.A. Bhatti, M. Asghar, Inter. J. Biolog. Macrom., 2018, 115, 375.

- F. Zhao, D. Yao, R. Guo, L. Deng, A. Dong, J. Zhang, Nanomater., 2015, 5, 2054.

- Z. Ounaies, C. Park, W.E. Wise, E.J. Siochi, J.S. Harrison, Comp. Sci. Techn., 2003, 63, 1637.

- M.C. Weisenberger, E.A. Grulke, D. Jacques, T. Ramtell, R. Andrews, J. Nanosci. Nanotechn., 2003, 3, 535.

- S. Iijima, Nature, 1991, 354, 56.

- Prateek, D. Singh. N. Singh, A. Garg, R.K. Gupta, Comp. Sci. Tech.,2019, 12, 158.

- D.R. Paul, L.M. Robeson, Polym., 2008, 49, 3187.

- H. Gleiter, Nanostru. Mater., 1992, 1, 1.

- X. Long, Y. Bai, M. Algarni, Y. Choi, Q. Chen, Mater. Sci. Eng., 2015, 645, 347.

- A.T. Lawal, Mater. Res. Bull., 2016, 73, 308.

- C.O. Oriakhi, Nano sandwiches. Chem. Br., 1998, 34, 59.

- P. Ajayan, O. Stephan, C. Colliex, D. Trauth, Sci., 1994, 265, 1212.

- D. Galpaya, Graphene, 2012, 1, 30.

- E. Tkalya, J. Mater. Chem., 2010, 20, 3035.

- S.K. Kumar, Mater. Lett., 2013, 96, 109.

- H. Kim, Y. Miura, C.W. Macosko, Chem. Mater., 2010, 22, 3441.

- L.S. Schadler, Nanocomposite Science and Technology: Wiley-VCH, 2004, 77.

- M. Berta, Polym., 2012, 53, 5771.

- E.R. Hitzky, P. Aranda, M. Darder, M. Ogawa, Chem. Soc. Rev., 2011, 40, 801.

- P.B. Messermith, E.P. Giannelis, Chem. Mater., 1994, 6, 1719.

- D.D.L. Chung, J. Mater. Sci., 1987, 22, 4190.

- D. Chen, P. He, Compo. Sci. Techn., 2004, 64, 2501.

- C. Park, O. Park, J. Lim, H. Kim, Polym., 2001, 42, 7465.

- H.R. Dennis, D. Hunter, D. Chang, S. Kim, D.R. Paul, Polym., 2001, 42, 9513.

- K.H. Ahn, D.H. Kim, U. Park, ANTEC, 2002, 1457.

- E.T. Thostenson, Z. Ren, T.W. Chou, Compo. Sci. Tech., 2001, 61, 1899.

- A. Pattanayak, S.C. Jana, Polym., 2005, 46, 3394.

- H. Lee and L. Lin, Macromol., 39 (2006) 6133;

- K. Wang, L. Chen, J. Wu, M.L. Toh, C. He, A.F. Yee, Macromol., 2005, 38, 788.

- M.I. Sarwar, S. Zulfiqar, Z. Ahmad, Polym. Int., 2008, 57, 292.

- D. Ponnamma, Mater. Sci. Engg. C , 2019, 98, 1210.

- C.S. Reddy, C.K. Das, J. Appl. Polym. Sci., 2006, 102, 2117.

- S. Yu, P. Hing, X. Hu, Compos. Part A, 2002, 33, 289.

- G. Lee, M. Park, J. Kim, J. Lee, H. Yoon, Compos. Part A, 2007, 37, 727.

- T. Wu, Y. Ke, Thin Sol. Films., 2007, 515, 5220.

- K. Wang, M. Choi, C. Koo, Y. Choi, I. Chung, Polym., 2001, 42, 9819.

- C. Huang, X. Qian, R. Yang, Mater. Sci. Engg., 2018, 132, 1.

- S.J. Su, N. Kuramoto, Synthet. Metal., 2000, 114, 147.

- C.C.M. Ma, Y.J. Chen, H.C. Kuan, J. Appl. Polym. Sci., 2006, 100, 508.

- A. Olad, A. Rashidzadeh, Prog. Org. Coat., 2008, 62, 293.

- Q. Tang, X. Sun, Q. Li, J. Lin, J. Wu, J. Mater. Sci., 2009, 44, 849.

- X. Zhang, L.C. Simon, Macromol. Mater. Eng., 2005, 290, 573.

- Y.H. Yu, C.C. Jen, H.Y. Huang, P.C. Wu, C.C. Huang, J.M. Yeh, J. Appl. Polym. Sci., 2004, 91, 3438.

- T.C. Mo, H.W. Wang, S.Y. Chen, Y.C. Yeh, Ceram. Int., 2008, 34, 1767.

- C. Xu, C. Ouyang, R. Jia, Y. Li and X. Wang, J. Appl. Polym. Sci., 2009, 111, 1763.

- Y.J Wang, D. Kim, Electrochim. Acta, 2007, 52, 3181.

- G.P. Pandey, R.C. Agrawal, S.A. Hashmi, J. Power Sour., 2009, 190, 563.

- R. Chai, H. Lian, P. Yang, Y. Fan, Z. Hou, X. Kang, J. Lin, J. Colloid. Interf. Sci., 2009, 336, 46.

- H. Wang, P. Xu, W. Zhong, L. Shen, Q. Du, Polym. Degrad. Stabil., 2005, 87, 319.

- D.K. Avasthi, Y.K. Mishra, D. Kabiraj, N.P. Lalla and J.C. Pivin, Nanotechnol., 2007, 18, 125604.

- J.L. H. Chau, C.T. Tung, Y.M. Lin, A.K. Li, Mater. Lett., 2008, 62, 3416.

- J. Alam, U. Riaz and S. Ahmad, J. Magn. Magn. Mater., 2007, 314, 93.