Research Article - Der Pharma Chemica ( 2021) Volume 13, Issue 11

Corrosion Inhibition of Hydrophobic Nano Film of Eco Friendly Banana peel Extract on Mild Steel in Seawater.

M Sangeetha1*, D Madhan2 and S Rajendran32Department of Physics, K.S.R Institute for Engineering and Technology, Tiruchengode, Tamilnadu, India

3Department of Chemistry, St Antony’s College of Arts and Science for women, Dindigul, India

M Sangeetha, Department of Chemistry, EMG Yadava Womens College, Madurai, Tamilnadu, India, Email: sangeethamanirevathi@gmail.com

Abstract

Eco friendly Hydrophobic nano film prepared from Banana Peel Extract (BPE) adsorbed on mild steel in seawater. The surface structure and composition were then characterized by means of Scanning Electron Microscopy (SEM) and Atomic Force Microscope (AFM) techniques. The electrochemical studies showed that the hydrophobic surface significantly improved the corrosion resistance of mild steel in seawater and it acts as a Mixed type of inhibitor. The Contact angle for the BPE inhibitor system on the surface was measured in 173°C.

Keywords

Hydrophobic film, Contact angle, Eco friendly, Banana peel extract, Mixed inhibitor.

Introduction

The phenomenon of corrosion is as old as the history of metals and it has been looked on as a menace which destroys metals and structures and turns beauty into a beast. Our human civilization cannot exist without metals and yet corrosion is their Achilles heel. The need growing for the corrosion inhibitors becomes increasingly necessary to stop or delay the attack of a metal in an aggressive solution. Considerable efforts are made to find suitable compounds to be used as corrosion inhibitors in various corrosive media. A number of heterocyclic compounds have been reported as corrosion inhibitors and the screening of synthetic heterocyclic compounds is still being continued. Several other inorganic inhibitors such as zinc, chromate, polyphosphate, and nitrite were used as corrosion inhibitors. Also, molybdate, phosphates, phosphonocarboxylic acids and polymers were used as inhibitors, along with metal ions such as Zn2+. Though many synthetic compounds showed good anticorrosive activity, most of them are highly toxic to both human beings and the environment. These toxic effects and ecological problems associated with the discharge of such materials have resulted in the development of other efficient and environmentally acceptable inhibitors. Hence the recent trend is the search for environmental friendly inhibitors. Most of the natural products are non-toxic, biodegradable and readily available in plenty. Various parts of the plants seeds, fruits, leaves, flowers, etc., have been used as corrosion inhibitors. Several studies have been published on the use of natural products as corrosion inhibitors.

Tannins are being used for protection of steel against corrosion in cooling water systems and in paints. The biocidal and inhibitive effects of Azadirachta Indica have been studied on mild steel in fresh water. The scale inhibition efficiencies of the aqueous extracts of plant materials, namely Cordia latifolia, Eucalyptus and Jasmine auriculatum have been evaluated. Corrosion inhibition has been studied with Eugenia jambolans, Androgaphis paniculata, Acacia Arabica. Kliskic, have used the first neutral phenol sub fraction of the aqueous extract of rosemary leaves as a corrosion inhibitor for the Al-Mg alloy in a 3% NaCl solution at 298 K. Lawsonia extract has been used to inhibit corrosion of metals. Corrosion inhibition of iron in hydrochloric acid solutions by naturally occurring henna has been investigated. The corrosion inhibition efficiency of a caffeine-Zn2+ system in mild steel immersed in an aqueous solution containing 60 ppm of chloride was investigated by weight loss study. Aqueous extract of kalmegh (Andrographis paniculata) leaves has been used as green inhibitor. Eco-friendly corrosion inhibitors garcinia kola has been used to prevent corrosion of mild steel in H2SO4 solutions. The inhibitory effects of ocinum Tenuiplorum (Tulsi) has been investigated. Anti-corrosive effect of Raphia hookeri exudates gum-halide mixtures have been studied. An ethanol extract of Phyllanthus amarus green inhibitor has been used to prevent the corrosion of mild steel in H2SO4.Terminalia Catappa extract has corrosion inhibitive property [1].

There are several reviews on the use of plant extracts corrosion inhibitors. Recently aqueous extract of Cocos nucifera Coconut Palm Petiole. Fennel (Foeniculum Vulgare) Essential Oil. Pericarp of the Fruit of Garcinia Mangostana. Natural Fenugreek. An ethanol extract of Vernonia Amygdalina Ipomoea involcrata ginger. Naturally occuring ginger as a corrosion inhibitor for steel in molar hydrocloric acid at 353 K.

Musa acuminata fruit peel extract in acid medium. Musa Paradisiaca extract in 0.5 M sulphuric acid solution. An ethanol extract of musa species peels as a green corrosion inhibitor. Inhibitory Effects of Ocimum Tenuiflorum (Tulsi) On the Corrosion of Zinc in Sulphuric Acid are studied by Sanjay K. Comparative Study of Corrosion Inhibition Efficiency of Holy Basil (Tulsi) for Tin in HNO3 Solution. Ocimum tenuiflorum leaves extract have been used as corrosion inhibitors. The present work is undertaken.

• To evaluate the inhibition efficiency (IE) of an aqueous extract of Banana peel (BPE) in controlling the corrosion of carbon steel in sea water, in the absence and presence of Zn2+

• To analyze the protective film formed on the carbon steel by Polarization study

• To evaluate the hydrophobic nature of the film by calculating contact angle of the metal surface

• To analyze the surface of the metal by SEM, and Atomic Force Microscope techniques.

Experimental Methods and Materials

Preparation of the specimen

Carbon steel specimens of size 1.0 cm × 4.0 cm × 0.2 cm and chemical composition 0.026 % Sulphur, 0.06 % Phosphorous, 0.4 % Manganese, 0.1 % Carbon and the rest iron were polished to a mirror finish and degreased with trichloroethylene and used for the weight loss method and surface examination studies.

Preparation of banana peel extract

An aqueous extract of Banana peel was prepared by grinding 10g of Banana peel, with distilled water, filtering the suspending impurities, and making up to 100 ml. The extract was used as corrosion inhibitor in the present study.

Weight-loss method

Carbon steel specimens were immersed in 100 ml of the sea water in [Nagarkovil, Tamilnadu, India] containing various concentrations of the inhibitor Banana Peel Extract (BPE) in the absence and presence of Zn2+ for one day. The weights of the specimens before and after immersion were determined using Digital Balance (Model AUY 220 SHIMADZU). The corrosion Inhibition Efficiency (IE) was then calculated using the equation

IE=100 [1-(W2/W1)] %

Where W1 is the weight loss value in the absence of inhibitor and W2 is the weight loss value in the presence of inhibitor

Surface examination study

The carbon steel specimens were immersed in various test solutions for a period of 1 day. After 1 day, the specimens were taken out and dried. The nature of the film formed on the surface of the metal specimen was analyzed by various surface analysis techniques.

Potentiodynamic polarization

Polarization studies were carried out in a CHI- electrochemical work station with impedance model 660A. It was provided with iR compensation facility. A three electrode cell assembly was used. The working electrode was carbon steel. A SCE was the reference electrode. Platinum was the counter electrode. From polarisation study, corrosion parameters such as corrosion potential (Ecorr), corrosion current (Icorr), Tafel slopes anodic = ba and cathodic = bc were calculated and polarization study was done. The scan rate (V/S) was 0.01. Hold time at (Efcs) was zero and quiet time (s) was two [2].

Contact angle measurement technique

The carbon steel were immersed in blank as well as in inhibitor solutions for a period of one day, after 1 day the specimens were taken out, rinsed with double distilled water, dried and hydrophobic nature of film formed on the metal surface was observed by placing a droplet of water on the metal surface, and the image of the droplet is captured using Nixon, Wide 5X Zoom, Cool PLX digital camera

Scanning electron microscopic studies (SEM)

The carbon steel immersed in blank solution and in the inhibitor solution for a period of one day was removed, rinsed with double distilled water, dried and observed with a scanning electron microscope to examine the surface morphology. The surface morphology measurements of carbon steel were examined using JEOL MODEL6390 computer controlled scanning electron microscope. The elemental analysis of the carbon steel surface of the same condition was carried out using an energy dispersive X-ray analyzer (EDAX) unit attached to the SEM machine [3].

Atomic force microscopy characterization (AFM)

The carbon steel specimen immersed in blank and in the inhibitor solution for a period of one day was removed, rinsed with double distilled water, dried and subjected to the surface examination. Atomic force microscopy (Veeco dinnova model) was used to observe the sample’s surface in tapping mode, using a cantilever with linear tips. The scanning area in the images was 5 μm × 5 μm and the scan rate was 0.6 HZ /second

Results and Discussion

The physicochemical parameters of the Sea water collected from Nagarkovil in the state of Tamil Nadu, India, are given in Table 1.

| Parameters | Value |

|---|---|

| Total dissolved salts (mg L-1) | 58564 |

| Electrical conductivity ( µΩ-1cm-1) | 39824 |

| pH | 7.4 |

| Total hardness (CaCO3 equivalent) | 6050 |

| Calcium as Ca2+ (mg L-1) | 1500 |

| Magnesium as Mg2+ (mg L-1) | 900 |

| Sodium as Na+ (mg L-1) | 9500 |

| Chloride as Cl- (mg L-1) | 18350 |

| Fluoride as F- (mg L-1) | 1.1 |

| Potassium (mg L-1) | 1100 |

Sulphate as SO42- (mg L-1 ) |

4354 |

Analysis of results of weight loss study

The calculated Inhibition efficiencies (IE) and corresponding corrosion rates of Banana Peel Extract (BPE) in controlling the corrosion of carbon steel immersed in the presence and absence of Zn2+ have been tabulated in Table 2. It is observed that aqueous extract of banana peel shows good Inhibition Efficiency (IE) (in the absence of Zn2+).When Zn2+ (5 ppm) is added IE decreases at first.

| BPE ( mL) | IE% Zn2+ (ppm) | CR mm/y Zn2+ (ppm) | ||||||

|---|---|---|---|---|---|---|---|---|

| 0 | 5 | 15 | 25 | 0 | 5 | 15 | 25 | |

| 0 | -- | 20 | 25 | 30 | 0.1623 | 0.1298 | 0.1217 | 0.1136 |

| 2 | 62 | 65 | 42 | 60 | 0.0616 | 0.0568 | 0.0941 | 0.0649 |

| 4 | 71 | 94 | 98 | 94 | 0.047 | 0.0097 | 0.0032 | 0.0097 |

| 6 | 57 | 90 | 90 | 82 | 0.0697 | 0.0162 | 0.0162 | 0.0292 |

| 8 | 48 | 82 | 84 | 80 | 0.0843 | 0.0292 | 0.0259 | 0.0324 |

When Zn2+ is added further, IE increases at 4 ml of BPE and 15 ppm of Zn2+. This formation gives 98 % IE. This may be due to the fact that, when the concentration of Zn2+ increases, the Zn2+-BPE complex formed is precipitated in the bulk of the solution. Hence BPE is not transported towards the metal surface. So the IE decreases. A similar observation was made by Hibiscus Rosa-Sinensis Al at pH 12, Euphorbia, Henna [4].

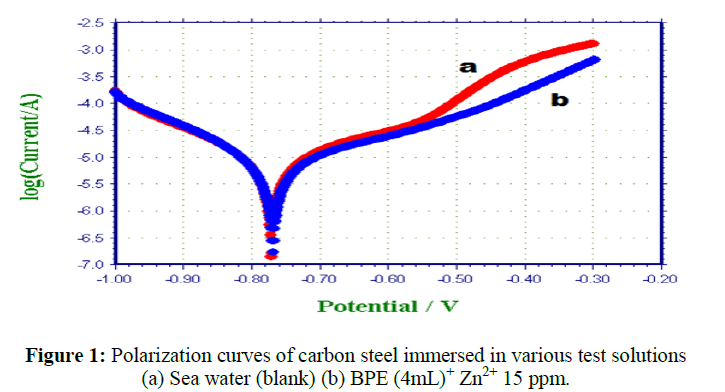

Analysis of polarization curves

Polarization study has been used to detect the formation of protective film on the metal surface. When a protective film is formed on the metal surface, the Linear Polarization Resistance (LPR) increases and the corrosion current (Icorr) decreases. The potentiodynamic polarization curves of carbon steel immersed in various test solutions are shown in Figure 1. The corrosion parameters namely, corrosion potential (Ecorr), Tafel slopes (bc = cathodic; ba = anodic), Linear Polarization Resistance (LPR) and corrosion current (Icorr) are given in Table 3. When carbon steel is immersed in sea water, the corrosion potential is -771 mV vs SCE. The formulation consisting of 4 mL of Banana Peel (BPE) and 15 ppm of Zn2+ shifts the corrosion potential to -769 mV vs SCE [5]. The shift in corrosion potential is very small. The observed variation in Ecorr is much less than + 85 mV and hence it cannot be classified as anodic or cathodic inhibitor.

| System | Ecorr mV vs SCE |

Bc mV/decade | ba mV/decade | LPR ohm cm2 | I corr A/cm2 |

|---|---|---|---|---|---|

| Sea water(blank) | -771 | 165 | 226 | 4852 | 8.579 × 10-6 |

| BPE(4mL)+ Zn2+ (15ppm) |

-769 | 151 | 240 | 5425 | 7.440 × 10-6 |

This suggests that this formulation controls the anodic reaction and cathodic reaction to an equal extant. So we can conclude that this inhibitor acts as mixed type of inhibitor. The LPR value increases from 4852 ohm cm2 to 5425 ohm cm2. This suggests that a protective film is formed on the metal surface. Further the corrosion current decreases from 8.579 × 10-6 A/cm2 to 7.440 × 10-6 A/cm2. The IE calculated from corrosion current is 52%. This value is lower than the IE obtained by weight loss method (98%). The discrepancy may be explained by the fact that in electrochemical process, the instantaneous corrosion current is measured. However, in the case of the weight loss method, IE is calculated after a long time. The protective film formed is strengthened as the duration of immersion increases.

In presence of inhibitors, the cathodic and anodic Tafel slopes are more or less equal when compared with sea water (blank). This indicates that the formulation consisting of BPE and Zn2+ functions as mixed type inhibitor controlling the cathodic reaction and anodic reaction to an equal extend. However the anodic Tafel slope is slightly higher. This is reflected in the shift of corrosion potential to the anodic side [6].

Contact angle measurement

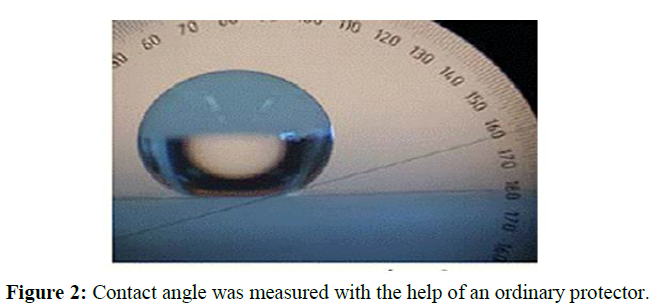

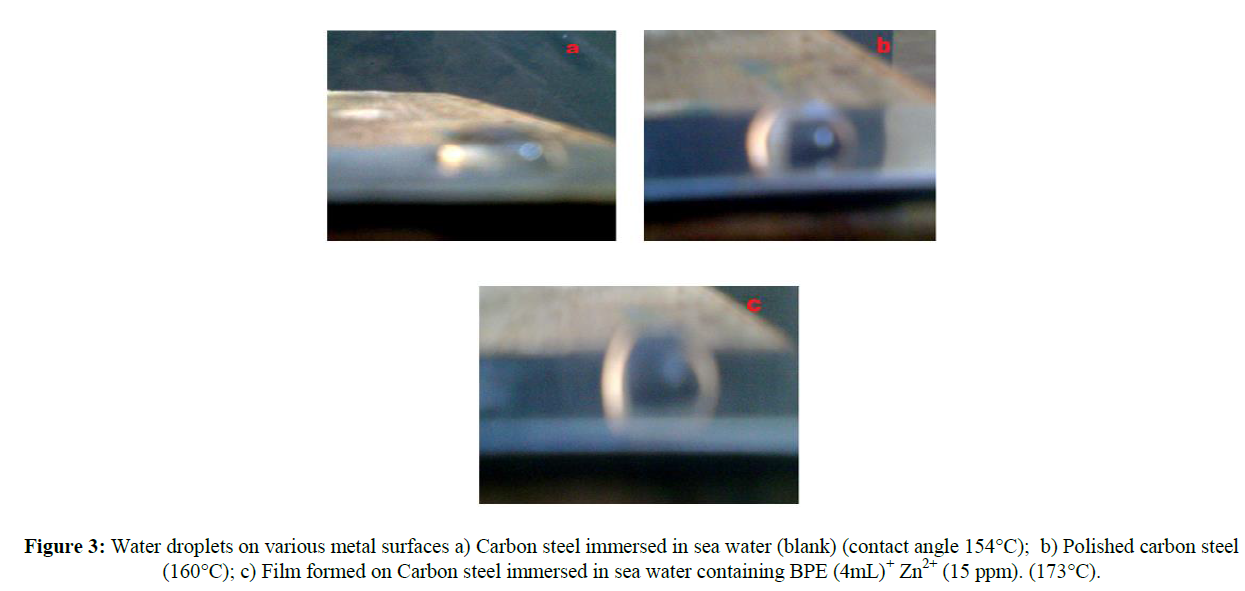

Contact angle of a water drop on the metal surface is a measure of hydrophobic nature of metal surface. As the contact angle increases the hydrophobicity of the surface increases .This means that water cannot penetrate the film and contact the metal surface. Hence corrosion inhibition increases. The contact angles of water droplets placed on various metal surfaces are given in table:4. The photos of the droplets, taken with an ordinary digital camera, are shown in Figures 2. The contact angle was measured with the help of an ordinary protector is given in the Scheme 1.

It is observed from the Table 4. That the contact angle of the polished surface is greater than that on the corroded surface (Blank). It is interesting to note that on the inhibited metal surface, the contact angle is higher (173°C). That is, this surface is relatively more hydrophobic than the other two surfaces. This accounts for the high corrosion inhibition efficiency of the inhibitor system, which encourages the formation of a hydrophobic film on the metal surface. The photographs of the water droplets on the metal surface were taken with an ordinary digital camera. The droplet on the corroded surface (blank) is flattened. That is contact angle is less? The droplet on the polished metal surface looks like a semicircle. But the droplet on the hydrophobic surface has a spherical shape. The contact angle is higher.

| Surface | Contact angle |

|---|---|

| Metal placed in sea water(Blank- corroded) | 154◦ |

| Polished metal | 160◦ |

| Film formed on the metal surface after immersion in seawater containing inhibitors (4 mL of inhibitor + 15 ppm of Zn2+) | 173◦ |

This accounts for the high inhibition efficiency of the inhibitor system. In the case of a higher inhibition efficiency system, the droplets are sitting on the hydrophobic films. That is, this system corresponds to cassie’s model. Usually, when water droplets sit on metal surface following cassie’s model, higher hydrophobicity and hence, higher corrosion inhibition is expected; and that is the case in present study also.

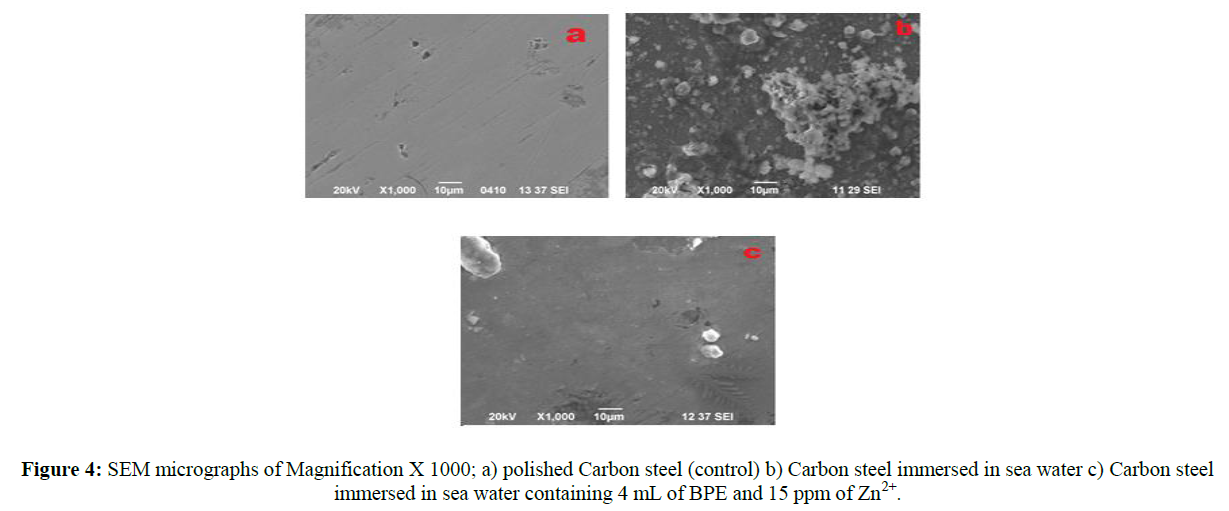

Surface characterization by scanning electron microscopy (SEM)

The SEM images (magnification X 1000) of carbon steel specimen immersed in sea water for 1 day in the absence and presence of inhibitor system are shown in Figure 3. The SEM is used to understand the nature of the surface film; SEM provides a pictorial representation of the surface. The SEM micrographs of polished carbon steel surface (control) in Figure 3 (a) illustrate the smooth surface of the metal. This shows the absence of any corrosion products formed on the metal surface. The SEM micrographs of the carbon steel surface immersed in sea water in Figure 3(b) shows the roughness of the metal surface which indicates the corrosion of carbon steel in seawater. Figure 3 (c) indicates that in presence of 15 ppm of Zn2+ BPE mixture in sea water, the surface coverage increases, which in turn results in the formation of insoluble complex on the surface of the metal (BPE-Zn2+ inhibitor complex) and the surface is covered by a thin layer of inhibitors which control the dissolution of carbon steel. Such results have been reported earlier.

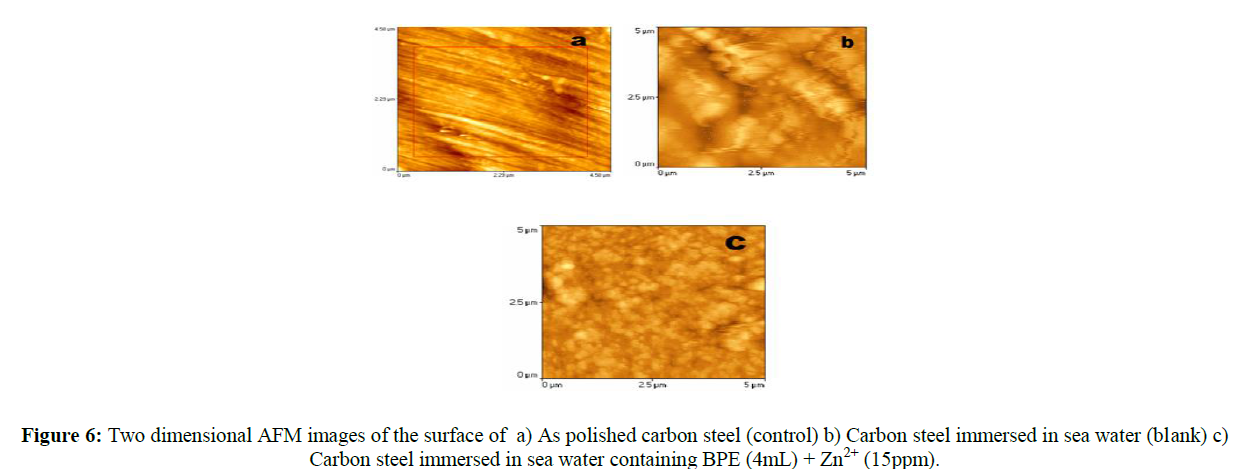

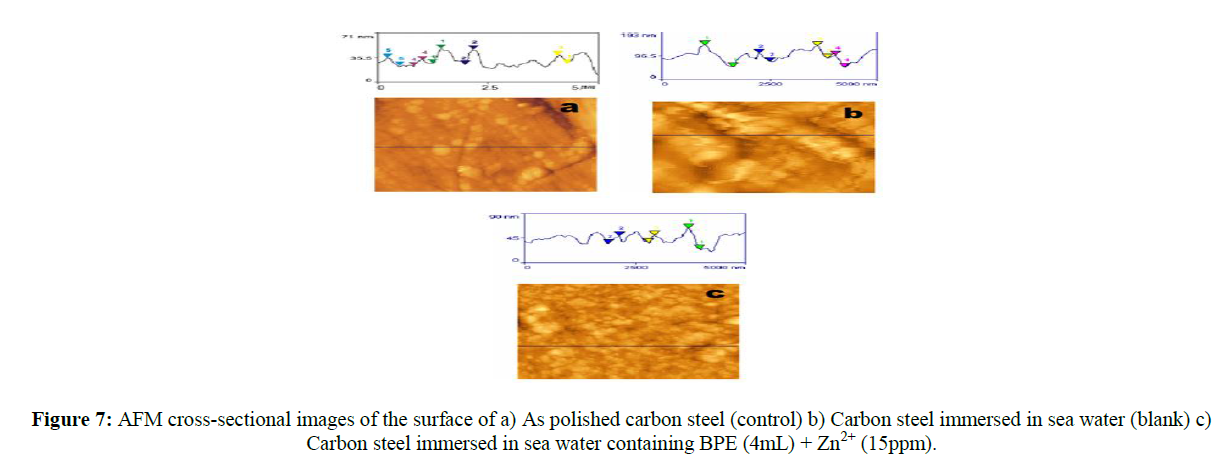

Surface characterization by atomic force microscopy (AFM)

Atomic Force Microscopy (AFM) is a powerful technique to investigative the surface morphology at nano to micro-scale and has become a new choice to study the influence of inhibitor on the generation and the progress of the corrosion at the metal/solution interface. The two dimensional (2D), and the AFM cross-sectional profile of polished carbon steel surface (reference sample), carbon steel surface immersed in sea water (blank sample) and carbon steel surface immersed in sea water containing the formulation of 4 mL of BPE and 15 ppm of Zn2+ are shown in Figure 4, and 5 respectively.

Root-mean-square roughness, average roughness and peak-to-valley value

AFM image analysis was performed to obtain the average roughness, Ra (the average deviation of all points roughness profile from a mean line over the evaluation length), root-mean-square roughness, Rq (the average of the measured height deviations taken within the evaluation length and measured from the mean line) and the maximum peak-to-valley (P-V) height values (largest single peak-to-valley height in five adjoining sampling heights). Table: 5 is a summary (Rq), (Ra), (P-V) value for carbon steel surface immersed indifferent environment [7].

Displays the surface topography of un-corroded metal surface. The value of Rq, Ra and P-V height for the polished carbon steel surface (reference sample) are 4.3 nm, 3.41nm and 35.28 nm respectively. The slight roughness observed on the polished carbon steel surface is due to atmospheric corrosion. Fig: 4b, 5b, displays the corroded metal surface with few pits in the absence of the inhibitor immersed in sea water. The (Rq), (Ra), (P-V) height values for the carbon steel surface are 25.2 nm, 19.9 nm and 89.10 nm respectively. These data suggests that carbon steel surface immersed in sea water has a greater surface roughness than the polished metal surface, which shows that the unprotected carbon steel surface is rougher and was due to the corrosion of the carbon steel in sea water environment. Figure 4c, 5c, displays the steel surface after immersion in sea water containing 4 mL of BPE and 15 ppm of Zn2+. The (Rq) value is reduced from 25.2 nm to 8.45 nm compared with corroded metal surface , (Ra) value is reduced to 6.50 nm from 19.9 nm, (P-V) maximum peak to valley height values also was reduced to 38.63 nm , The (Rq), (Ra), (P-V) height values are considerably less in the inhibited environment compared to the uninhibited environment. These parameters confirm that the surface is smoother. The smoothness of the surface is due to the formation of a compact protective film of Fe2+ - BPE complex thereby inhibiting the corrosion of carbon steel [8].

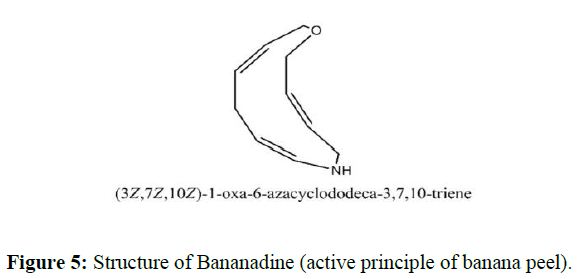

The comparison of the root mean square (rms) roughness and Average (Ra) roughness of the unmodified substrate to the modified samples is an indicator of the film uniformity. The rms roughness parameter is a measure of the deviations in the surface of the mean plane within the sampling area. Modified surfaces with a rms roughness similar to the control surface are considered to be films of monolayer thickness that follow the contour of the surface, while modified surfaces that have much larger rms roughness than the control are multilayer or non-uniform films. When we see the Table 5, The rms roughness of the substrate (4.33 nm) change very much after the adsorption of BPE (bananadine) molecules (8.57 nm) and average roughness is also changes to (6.5 nm) when compared to polished substrate (3.41 nm).This suggests non-uniform deposition of the organic molecules on the surface. Therefore, it is concluded that within the scope of the analysis, the film formed is a nano film of molecules that follows the contour of the underlying substrate. While the film acts as a hydrophobic and show high corrosion resistance. The active principle present in banana peel is bananadine.

| Samples | RMS(Rq) Roughness (nm) | Average(Ra) Roughness (nm) | Maximum Peak-to valley Height (nm) |

|---|---|---|---|

| 1.Polished carbon steel | 4.33 | 3.41 | 35.28 |

| 2.Carbon steel immersed in sea water |

25.2 | 19.9 | 89.1 |

| 3.Carbon steel immersed in sea water + BPE (4mL) + Zn2+ (15ppm) |

8.45 | 6.5 | 38.63 |

Conclusion

The present study leads to the following conclusions. The formulation consisting of 4ml of BPE and 15 ppm of Zn2+ offers 98% inhibition efficiency to carbon steel immersed in sea water. Polarization study reveals that this system formulation acts as a mixed type of inhibitor. SEM studies confirm the formation of protective on the metal surface in the presence of sea water. AFM studies confirm that the surface is smoother and it forms monolayer. The smoothness of the surface is due to the formation of a compact protective film of Fe2+. BPE complex on the metal surface thereby inhibiting the corrosion of carbon steel. Hydrophobic nature of the film is proven by calculating contact angle (173◦) of the metal surface.

References

- F Bentiss, M Traisnel, M Lagrenee, Corros Sci, 2000, 42: p. 127.

- ST Arab, EA Noor, Corrosion, 1993, 49: p. 122.

- H Luo, YC Guan, KN Han, Corrosion, 1988, 54: p. 721.

- K Srivastava, P Srivastava, Br Corros J, 1981, 16: p. 221.

- RM Saleh, AA Ismail, AA El Hosary, Br Corros J, 1982, 16: p. 131.

- AJ Saevell, J Oil Col Chem Assn, 1978, 61: p. 439.

- E Knowles, T White, J Oil Col Chem Assn, 1958, 41: p. 10.

- TK Ross, RA Francis, Corros Sci, 1978, 18: p. 351.