Research Article - Der Pharma Chemica ( 2023) Volume 15, Issue 3

A NEW ANALYTICAL RP-HPLC METHOD FOR THE ESTIMATION OF VEMURAFENIB IN PURE FORM AND MARKETED PHARMACEUTICAL DOSAGE FORM

Nilima Shukla, Pragati Ranjan Satpathy*, Madhu Chhanda Mishra, Bisakha Tripathy and Bhavna GhoshPragati Ranjan Satpathy, Department of Pharmaceutical Analysis, Sri Jayadev College of Pharmaceutical Sciences, Naharkanta, Bhubaneswar 752101, India, Email: pharm.prsatpathy@gmail.com

Received: 27-Feb-2023, Manuscript No. dpc-23-90310; Editor assigned: 01-Mar-2023, Pre QC No. dpc-23-90310; Reviewed: 15-Mar-2023, QC No. dpc-23-90310; Revised: 17-Mar-2023, Manuscript No. dpc-23-90310; Published: 24-Mar-2023, DOI: 10.4172/0975-413X.15.3.16-25

Abstract

The analytical method was developed and validated for estimation of Vemurafenib in bulk and marketed formulation by Reverse Phase - High performance liquid chromatography. The separation was carried out on Symmetry C18 (4.6mm × 150mm) 5μm column. The mobile phase consists methanol and water were consists of 45:55% v/v) at flow rate 1.0 ml/min at 260nm. The column temperature was adjusted at 40°C with injection volume 10μl. The retention time of Vemurafenib was found to be 2.379 min. The linearity of the calibration curve was linear over the concentration range 24-120 μg/ml. The developed method was validated according to the International Council for Harmonization (ICH) Guidelines. The method was validated for specificity, linearity, accuracy, precision, LOD, LOQ and robustness. The developed method was easy, rapid, linear, precise, accurate and consistent. So, the method can be successfully applied for the routine analysis of Vemurafenib in bulk and marketed pharmaceutical formulation.

Keywords

Vemurafenib; RP-HPLC; Method Development; Validation; ICH Guidelines

INTRODUCTION

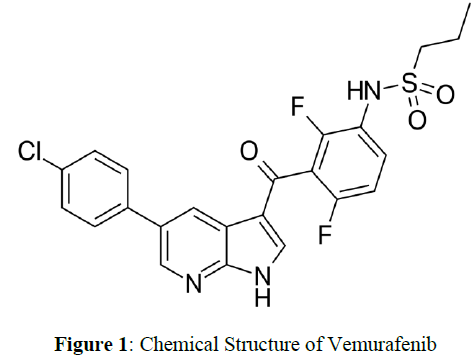

Vemurafenib is an orally bioavailable, ATP-competitive, small-molecule inhibitor of BRAF (V600E) kinase with potential antineoplastic activity. Vemurafenib [1] selectively binds to the ATP-binding site of BRAF (V600E) kinase and inhibits its activity, which may result in an inhibition of an over-activated MAPK signaling pathway downstream in BRAF (V600E) kinase-expressing tumor cells and a reduction in tumor cell proliferation. Approximately 90% of BRAF gene mutations involve a valine-to-glutamic acid mutation at residue 600 (V600E); the oncogene protein product, BRAF (V600E) kinase, exhibits a markedly elevated activity that over-activates the MAPK signaling pathway. The BRAF (V600E) gene mutation has been found to occur in approximately 60% of melanomas, and in about 8% of all solid tumors, including melanoma, colorectal, thyroid and other cancers. Vemurafenib [2] is a selective inhibitor of BRAF kinase that is used in the therapy of patients with metastatic and advanced malignant melanoma. Vemurafenib therapy is commonly associated with transient elevations in serum aminotransferase during therapy and has been linked to rare, but occasionally severe cases of clinically apparent acute liver injury. Vemurafenib [3] is a pyrrolopyridine that is 1H-pyrrolo [2, 3-b] pyridine which is substituted at position 5 by a p-chlorophenyl group and at positions 3 by a 3-amino-2, 6-difluorobenzoyl group, the amino group of which has undergone formal condensation with propane-1-sulfonic acid to give the corresponding sulfonamide. An inhibitor of BRAF and other kinases. It has a role as an antineoplastic agent and a B-Raf inhibitor. It is a pyrrolopyridine, a sulfonamide, a member of monochlorobenzenes, a difluorobenzene and an aromatic ketone. The IUPAC Name of Vemurafenib is N-[3-[5-(4-chloro phenyl)-1H-pyrrolo [2, 3-b] pyridine-3-carbonyl]-2, 4-difluoro phenyl] propane-1-sulfonamide. The Chemical Structure of Vemurafenib is as following (Figure 1).

Literature survey [4-7] reveals that only one enantiomeric, simple, rapid, chromatographic method in bulk and marketed pharmaceutical dosage forms by UV, RP-HPLC, UPLC and LC-MS methods has been reported for the estimation of Vemurafenib. The aim of the present study is to develop a simple, precise and accurate, economic stability indicating reversed-phase HPLC method for the estimation of Vemurafenib in bulk and marketed pharmaceutical dosage form as per ICH guidelines.

MATERIALS AND METHODS

Instruments Used (Table 1)

Chemicals used (Table 2)

| S.No. | Instruments and Glasswares | Model |

|---|---|---|

| 1 | HPLC | WATERS Alliance 2695 separation module, Software: Empower 2, PDA 996 Detector. |

| 2 | pH meter | Lab India |

| 3 | Weighing machine | Sartorius |

| 4 | Volumetric flasks | Borosil |

| 5 | Pipettes and Burettes | Borosil |

| 6 | Beakers | Borosil |

| 7 | Digital ultra sonicator | Labman |

| S.No. | Chemical | Brand names |

|---|---|---|

| 1 | Vemurafenib (Pure) | Local Market |

| 2 | Water and Methanol for HPLC | LICHROSOLV (MERCK) |

| 3 | Acetonitrile for HPLC | Merck |

HPLC Method Development

Preparation of Standard Solution

Accurately weigh and transfer 10 mg of Vemurafenib working standard into a 10ml of clean dry volumetric flasks add about 7ml of Methanol and sonicate to dissolve and removal of air completely and make volume up to the mark with the same Methanol.

Further pipette 0.72ml of the above Vemurafenib stock solutions into a 10ml volumetric flask and dilute up to the mark with Methanol.

Procedure

Inject the samples by changing the chromatographic conditions and record the chromatograms, note the conditions of proper peak elution for performing validation parameters as per ICH guidelines.

Mobile Phase Optimization

Initially the mobile phase tried was methanol: Water and Acetonitrile: Water with varying proportions. Finally, the mobile phase was optimized to Methanol and Water in proportion 45:55 v/v respectively.

Optimization of Column

The method was performed with various C18 columns like ODS column, Xterra, and X Bridge C18 column. Symmetry C18 (4.6mm x 150mm, 5μm) was found to be ideal as it gave good peak shape and resolution at 1.0ml/min flow.

Preparation of Mobile Phase

Accurately measured 450 ml (45%) of HPLC Methanol and 550 ml of HPLC Water (55%) were mixed and degassed in a digital ultrasonicator for 10 minutes and then filtered through 0.45 μ filter under vacuum filtration [8].

Diluent Preparation

The Mobile phase was used as the diluent.

Method Validation Parameters

System Suitability

Accurately weigh and transfer 10 mg of Vemurafenib working standard into a 10ml of clean dry volumetric flasks add about 7mL of Diluents and sonicate to dissolve it completely and make volume up to the mark with the same solvent. (Stock solution).

Further pipette 0.72ml of the above Vemurafenib stock solution into a 10ml volumetric flask and dilute up to the mark with diluents.

Procedure

The standard solution was injected for five times and measured the area for all five injections in HPLC. The %RSD for the area of five replicate injections was found to be within the specified limits.

Specificity

Preparation of Standard Solution

Accurately weigh and transfer 10 mg of Vemurafenib working standard into a 10ml of clean dry volumetric flasks add about 7ml of Diluents and sonicate to dissolve it completely and make volume up to the mark with the same solvent. (Stock solution)

Further pipette 0.72ml of the above Vemurafenib stock solutions into a 10ml volumetric flask and dilute up to the mark with diluents.

Preparation of Sample Solution

Take average weight of the Tablet and crush in a mortar by using pestle and weight 10 mg equivalent weight of Vemurafenib sample into a 10mL clean dry volumetric flask and add about 7mL of Diluent and sonicate to dissolve it completely and make volume up to the mark with the same solvent.

Further pipette 0.72ml of Vemurafenib above stock solution into a 10ml volumetric flask and dilute up to the mark with diluent.

Procedure

Inject the three replicate injections of standard and sample solutions and calculate the assay by using formula:

Linearity

Accurately weigh and transfer 10 mg of Vemurafenib working standard into a 10ml of clean dry volumetric flasks add about 7ml of Diluents and sonicate to dissolve it completely and make volume up to the mark with the same solvent. (Stock solution)

Preparation of Level – I (24ppm of Vemurafenib)

Pipette out 0.24ml of stock solution in to a 10ml volumetric flask and make up the volume up to mark by using diluent.

Preparation of Level – II (48ppm of Vemurafenib)

Pipette out 0.48ml of stock solution in to a 10ml volumetric flask and make up the volume up to mark by using diluent.

Preparation of Level – III (72ppm of Vemurafenib)

Pipette out 0.72ml of stock solution in to a 10ml volumetric flask and make up the volume up to mark by using diluent.

Preparation of Level – IV (96ppm of Vemurafenib)

Pipette out 0.96ml of stock solution in to a 10ml volumetric flask and make up the volume up to mark by using diluent.

Preparation of Level – V (120ppm of Vemurafenib)

Pipette out 1.2ml of stock solution in to a 10ml volumetric flask and make up the volume up to mark by using diluent.

Procedure

Inject each level into the chromatographic system and measure the peak area. Plot a graph of peak area versus concentration (on X-axis concentration and on Y-axis Peak area) and calculate the correlation coefficient [9].

Precision

Repeatability

Preparation of Vemurafenib Product Solution for Precision:

Accurately weigh and transfer 10 mg of Vemurafenib working standard into a 10ml of clean dry volumetric flasks add about 7ml of Diluents and sonicate to dissolve it completely and make volume up to the mark with the same solvent. (Stock solution) Further pipette 0.72 ml of the above Vemurafenib stock solutions into a 10ml volumetric flask and dilute up to the mark with diluents.

The standard solution was injected for five times and measured the area for all five injections in HPLC. The %RSD for the area of five replicate injections was found to be within the specified limits.

Intermediate Precision

To evaluate the intermediate precision (also known as Ruggedness) of the method, Precision was performed on different days by maintaining same conditions.

Procedure

Day 1

The standard solution was injected for six times and measured the area for all six injections in HPLC. The %RSD for the area of six replicate injections was found to be within the specified limits.

Day 2

The standard solution was injected for six times and measured the area for all six injections in HPLC. The %RSD for the area of six replicate injections was found to be within the specified limits.

Accuracy

For preparation of 50% Standard Stock Solution

Accurately weigh and transfer 10 mg of Vemurafenib working standard into a 10ml of clean dry volumetric flasks add about 7mL of Diluents and sonicate to dissolve it completely and make volume up to the mark with the same solvent. (Stock solution)

Further pipette 0.36ml of the above Vemurafenib stock solution into a 10ml volumetric flask and dilute up to the mark with diluents.

For preparation of 100% Standard Stock Solution

Accurately weigh and transfer 10 mg of Vemurafenib working standard into a 10ml of clean dry volumetric flasks add about 7mL of Diluents and sonicate to dissolve it completely and make volume up to the mark with the same solvent. (Stock solution)

Further pipette 0.72ml of the above Vemurafenib stock solution into a 10ml volumetric flask and dilute up to the mark with diluents.

For preparation of 150% Standard Stock Solution

Accurately weigh and transfer 10 mg of Vemurafenib working standard into a 10ml of clean dry volumetric flasks add about 7mL of Diluents and sonicate to dissolve it completely and make volume up to the mark with the same solvent. (Stock solution)

Further pipette 1.08ml of the above Vemurafenib stock solution into a 10ml volumetric flask and dilute up to the mark with diluents.

Procedure

Inject the Three replicate injections of individual concentrations (50%, 100%, 150%) were made under the optimized conditions. Recorded the chromatograms and measured the peak responses. Calculate the Amount found and Amount added for Vemurafenib and calculate the individual recovery and mean recovery values [10].

Robustness

The analysis was performed in different conditions to find the variability of test results. The following conditions are checked for variation of results.

For preparation of Standard Solution

Accurately weigh and transfer 10 mg of Vemurafenib working standard into a 10ml of clean dry volumetric flasks add about 7mL of Diluents and sonicate to dissolve it completely and make volume up to the mark with the same solvent. (Stock solution)

Further pipette 0.72ml of the above Vemurafenib stock solution into a 10ml volumetric flask and dilute up to the mark with diluents.

Effect of Variation of Flow Conditions

The sample was analyzed at 0.7 ml/min and 0.9 ml/min instead of 0.8ml/min, remaining conditions are same. 10μl of the above sample was injected and chromatograms were recorded.

Effect of Variation of Mobile Phase Organic Composition

The sample was analyzed by variation of mobile phase i.e. Methanol: Water was taken in the ratio and 40:60, 50:50 instead of 45:55, remaining conditions are same.10μl of the above sample was injected and chromatograms were recorded.

RESULTS AND DISCUSSION

Method Development

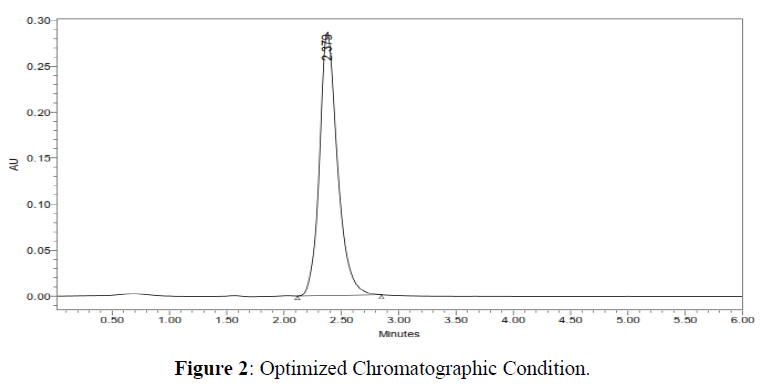

Several trials were made to get good peak resolution, acceptable plate count & tailing factor. Method was optimized for the estimation of Vemurafenib in bulk and marketed pharmaceutical dosage form (Figure 2).

Mobile phase ratio : Methanol: water (45:55 v/v)

Column : Symmetry C18 (4.6×150mm) 5µ

Column temperature : 40ºC

Wavelength : 260nm

Flow rate : 0.8ml/min

Injection volume : 10µl

Run time : 6.0 minutesValidation of Method

System Suitability

The system suitability studies [11-13] is concerned as per ICH guidelines [14]. The parameter like capacity factor, tailing factor, asymmetry factor & number of theoretical plate, and resolution were calculated (Table 3).

| S.No. | Peak Name | RT | Area (µV*sec) | Height (µV) | USP Plate Count | USP Tailing |

|---|---|---|---|---|---|---|

| 1 | Vemurafenib | 2.317 | 2274631 | 239458 | 5728 | 1.2 |

| 2 | Vemurafenib | 2.302 | 2284721 | 239582 | 5093 | 1.2 |

| 3 | Vemurafenib | 2.323 | 2238127 | 236493 | 5391 | 1.2 |

| 4 | Vemurafenib | 2.343 | 2259349 | 249482 | 6139 | 1.2 |

| 5 | Vemurafenib | 2.321 | 2204850 | 239452 | 5281 | 1.2 |

| Mean | 2252336 | |||||

| Std. Dev. | 31827.08 | |||||

| % RSD | 1.41307 |

Specificity

The analyte should have no interference from other extraneous components and be well resolved from them. Specificity [15] is a procedure to detect quantitatively the analyte in presence of component that may be expected to be present in the sample matrix, while selectivity is the procedure to detect qualitatively the analyte in presence of components that may be expected to be present in the sample matrix. The method was quite selective. There was no other interfering peak around the retention time of Vemurafenib; also the base line did not show any significant noise. The evaluation of the specificity of the method was determined against stress (forced) degradation application.

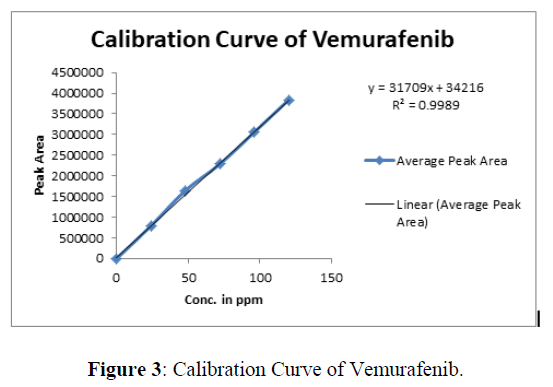

Linearity

Linearity was tested for the drug i.e. Vemurafenib, for the concentration 24 -120 μg/ml of Vemurafenib. The response factors were plotted against corresponding concentration of Vemurafenib to obtain the calibration curve [16,17] (Table 4) (Figure 3).

| Concentration Level (%) | Concentration mg/ml |

Average Peak Area |

|---|---|---|

| 33 | 24 | 791554 |

| 66 | 48 | 1647073 |

| 100 | 72 | 2283804 |

| 133 | 96 | 3058339 |

| 166 | 120 | 3839630 |

Chromatographic Data for Linearity Study

Linearity Plot

The plot of Concentration (x) versus the Average Peak Area (y) data of Vemurafenib is a straight line.

Y = mx + c

Slope (m) = 31709

Intercept (c) = 34216

Correlation Coefficient (r) = 0.998

Validation Criteria: The response linearity is verified if the Correlation Coefficient is 0.99 or greater [18].

Conclusion: Correlation Coefficient (r) is 0.99, and the intercept is 34216. These values meet the validation criteria.

Precision

The precision of an analytical procedure expresses the closeness of agreement (degree of scatter) between a series of measurements obtained from multiple sampling of the same homogeneous sample under the prescribed conditions [19] (Table 5).

| S. No. | Peak Name | Retention time | Area (µV*sec) | Height (µV) |

USP Plate Count | USP Tailing |

|---|---|---|---|---|---|---|

| 1 | Vemurafenib | 2.356 | 2259464 | 245362 | 5938 | 1.2 |

| 2 | Vemurafenib | 2.356 | 2275915 | 248293 | 5827 | 1.2 |

| 3 | Vemurafenib | 2.357 | 2282117 | 240795 | 5032 | 1.2 |

| 4 | Vemurafenib | 2.358 | 2278675 | 230139 | 5978 | 1.2 |

| 5 | Vemurafenib | 2.359 | 2282448 | 249605 | 6183 | 1.2 |

| Mean | 2275724 | |||||

| Std. Dev | 9476.485 | |||||

| %RSD | 0.416416 |

Repeatability

Obtained Five (5) replicates of 100% accuracy solution as per experimental conditions. Recorded the peak areas and calculated % RSD [20].

Intermediate Precision (Table 6)

| S.No. | Peak Name | RT | Area (µV*sec) | Height (µV) | USPPlate count | USPTailing |

|---|---|---|---|---|---|---|

| 1 | Vemurafenib | 2.380 | 2236184 | 202188 | 5472 | 1.2 |

| 2 | Vemurafenib | 2.383 | 2238020 | 201837 | 6193 | 1.2 |

| 3 | Vemurafenib | 2.385 | 2239352 | 201273 | 5980 | 1.2 |

| 4 | Vemurafenib | 2.385 | 2242466 | 203923 | 7163 | 1.2 |

| 5 | Vemurafenib | 2.389 | 2244692 | 202938 | 6182 | 1.2 |

| 6 | Vemurafenib | 2.389 | 2247654 | 201982 | 7684 | 1.2 |

| Mean | 2241395 | |||||

| Std. Dev. | 4333.851 | |||||

| % RSD | 0.193355 |

Analyst-1

Analyst 2 (Table 7)

| S.No. | Peak Name | RT | Area (µV*sec) | Height (µV) | USPPlate count | USPTailing |

|---|---|---|---|---|---|---|

| 1 | Vemurafenib | 2.380 | 2236184 | 217363 | 5928 | 1.2 |

| 2 | Vemurafenib | 2.383 | 2238020 | 218467 | 6183 | 1.2 |

| 3 | Vemurafenib | 2.385 | 2239352 | 218346 | 5927 | 1.2 |

| 4 | Vemurafenib | 2.385 | 2242466 | 221736 | 5163 | 1.2 |

| 5 | Vemurafenib | 2.389 | 2244692 | 228361 | 4827 | 1.2 |

| 6 | Vemurafenib | 2.346 | 2263431 | 217553 | 5019 | 1.2 |

| Mean | 2244024 | |||||

| Std. Dev. | 9988.458 | |||||

| % RSD | 0.445114 |

Accuracy

To check the accuracy of the method, recovery studies were carried out by adding the standard drug to at three different level 50%, 100%, 150% and amount recovered and % RSD was calculated for the drug (Table 8).

| %Concentration (at specification Level) |

Area | Amount Added (ppm) |

Amount Found (ppm) |

% Recovery | Mean Recovery |

|---|---|---|---|---|---|

| 50% | 1172485 | 36 | 35.8 | 99.4 | 99.5% |

| 100% | 2314753 | 72 | 71.6 | 99.4 | |

| 150% | 3480210 | 108 | 107.9 | 99. 9 |

The detection limit of an individual analytical procedure is the lowest amount of analyte in a sample which can be detected but not necessarily quantitated as an exact value.

LOD= 3.3 × σ / s

Where

σ = Standard deviation of the response

S = Slope of the calibration curve

Result

= 5.5μg/ml

Quantitation Limit

The quantitation limit of an individual analytical procedure is the lowest amount of analyte in a sample which can be quantitatively determined [21].

LOQ = 10×σ/S

Where

σ = Standard deviation of the response

S = Slope of the calibration curve

Result

= 16.7μg/ml

Robustness

The robustness was performed for the flow rate variations from 0.7 ml/min to 0.9ml/min and mobile phase ratio variation from more organic phase to less organic phase ratio for Vemurafenib [22]. The method is robust only in less flow condition and the method is robust even by change in the Mobile phase ± 5%. The standard and samples of Vemurafenib were injected by changing the conditions of chromatography. There was no significant change in the parameters like resolution, tailing factor, asymmetric factor, and plate count (Table 9).

| Parameter used for sample analysis | Peak Area | Retention Time | Theoretical plates | Tailing factor |

|---|---|---|---|---|

| Actual Flow rate of 0.8mL/min | 3119086 | 2.379 | 5837 | 1.2 |

| Less Flow rate of 0.7mL/min | 2640811 | 2.763 | 5361 | 1.2 |

| More Flow rate of 0.9mL/min | 2640354 | 2.234 | 5231 | 1.2 |

| Less organic phase | 2640758 | 2.765 | 4503 | 1.5 |

| More organic phase | 2640125 | 2.236 | 4491 | 1.5 |

CONCLUSOIN

The analytical method was developed by studying different parameters. First of all, maximum absorbance was found to be at 260nm and the peak purity was excellent. Injection volume was selected to be 10μl which gave a good peak area. The column used for study was Symmetry C18 because it was giving good peak. 40º C temperatures was found to be suitable for the nature of drug solution. The flow rate was fixed at 0.8ml/min because of good peak area and satisfactory retention time.

Mobile phase is Methanol: water was fixed due to good symmetrical peak. So this mobile phase was used for the proposed study. Methanol: water was selected because of maximum extraction sonication time was fixed to be 10min at which all the drug particles were completely soluble and showed good recovery. Run time was selected to be 6min because analyze gave peak around 2.3 and also to reduce the total run time.

The percent recovery was found to be 98.0-102 was linear and precise over the same range. Both system and method precision was found to be accurate and well within range. The analytical method was found linearity over the range of 24-120ppm of the Vemurafenib target concentration. The analytical passed both robustness and ruggedness tests. On both cases, relative standard deviation was well satisfactory. In the present investigation, a simple, sensitive, precise and accurate RP-HPLC method was developed for the quantitative estimation of Vemurafenib in bulk drug and pharmaceutical dosage forms.

This method was simple, since diluted samples are directly used without any preliminary chemical derivatization or purification steps. The %RSD values were within 2 and the method was found to be precise. The results expressed in Tables for RP-HPLC method was promising. The RP-HPLC method is more sensitive, accurate and precise compared to the Spectrophotometric methods. This method can be used for the routine determination of Vemurafenib in bulk drug and in Pharmaceutical dosage forms.

AKNOWLEDGEMENTS

Authors would like to express their best wishes to Sri Jayadev College of Pharmaceutical Sciences, Naharkanta, Bhubaneswar and Synpharma Research lab, Hyderabad, Telangana, India for their co-operation.

REFERENCES

- https://go.drugbank.com/drugs/DB08881

- https://en.wikipedia.org/wiki/Vemurafenib

- https://pubchem.ncbi.nlm.nih.gov/compound/Vemurafenib

- Swartz M, Murphy B. Am Lab. 2005, 37(3): 22-27.

- Swartz M. Pharm. Formulation quality. 2004, 6(5): p. 40-42.

- Biomedical Chromatography: BMC. 2008, 22(5): p. 469-477.

- Analytical Technologies in the Biomedical and life Sciences. 2008, 863(2): p. 258-265.

- García-Encina G, Farrán R, Puig S, et al., J Pharm Biomed Anal. 1999, 2: p. 371–382.

- Pujeri SS, Khader AMA, Seetharamappa J. Der Pharmacia Lettre. 2012, 4 (1):76-86.

- Samir V, Ajay P, Kartik D, et al., J Pharm Bioallied Sci. 2011, 3(2): p. 310-314.

- Bhandage A, Bhosale A, Kasture A. Trop J Pharm Res. 2009, 8(5): p. 449-454.

- Ravisankar P, Gowthami S, Devlala Rao G. IJCRT. 2022, 10(1): p. 18-6.

- Lloyd R. Snyder. Practical HPLC Method Development. 2nd edition, 2012, p.503.

- Guidance for industry, Analytical Procedure and Method Validation, U.S. Department of Health and Human Services FDA, August 2000.

- Cheng YF, Walter TH, Lu Z, et al., LCGC. 2000, 18(10): p. 1162.

- The United State Pharmacopeia 25/National Formulary 20, Ch. 1225, p. 2256-2259.

- ICH Q2B: Validation of Analytical Procedure; Methodology (International Conferences on Harmonization of Technical requirements for the registration of Drugs for Human use, Geneva, Switzerland, May 1997)

- ICH Q2B: Validation of Analytical Procedure; Methodology (International Conferences on Harmonization of Technical requirements for the registration of Drugs for Human use, Geneva, Switzerland, Nov 2003)

- Gorenstein MV, Li JB, Van Antwerp J. LCGC. 1994, 12(10): p. 768-772.

- Young PM and Gorenstein MV. LCGC. 1994, 12(11): p. 832-838.

- Warren WJ, Stanick WA, Gorenstein MV, et al., Bio techniques. 1995, 2: p. 282-297.

- Swartz ME. J liquid chromatography. 2005, 28: p. 1253-1263.

Indexed at, Google Scholar, Crossref

Indexed at, Google Scholar, Crossref